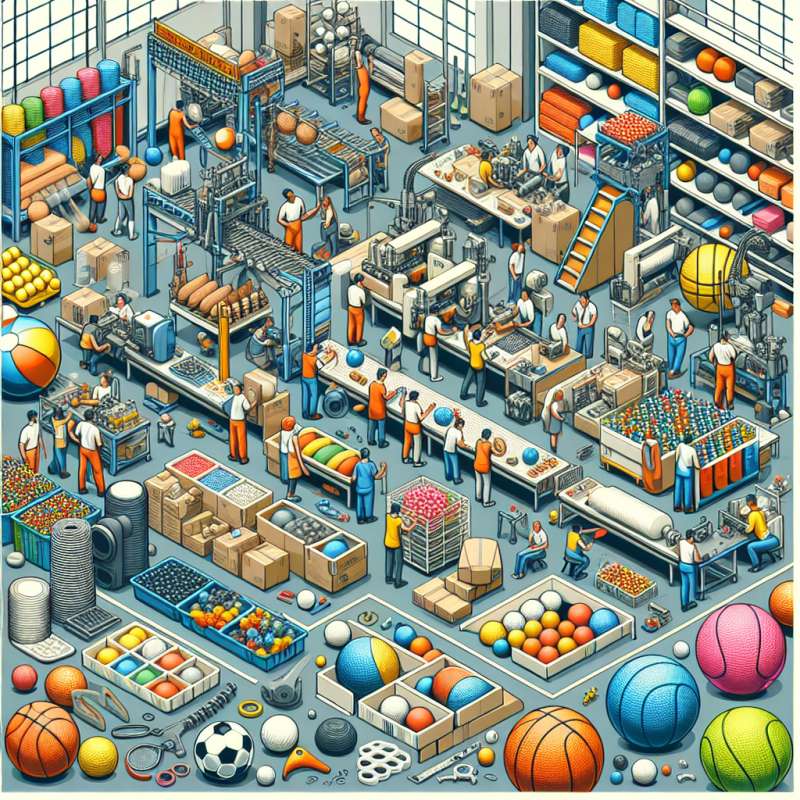

在橡膠製造工廠中,品質控制是至關重要的環節。製造橡膠製品需要遵循一系列複雜的製造工藝,從原料的選擇到產品檢測,每個步驟都需要受到嚴格的品質控制。

橡膠製品的製造工藝包括製品設計、橡膠配方的調配、橡膠材料的製備、製造過程的控制以及最終的產品檢測等步驟。在製造過程中,製造廠必須嚴格控制每一個細節,以確保產品的品質符合客戶的要求。

品質控制在整個生產線上起著至關重要的作用。從原料的檢驗到生產過程中的監控,再到最終產品的檢測,每個環節都需要嚴格的品質控制。製造工廠必須擁有先進的設備和技術,以確保製造過程中的品質控制得以有效執行。

橡膠製造廠在產能規劃、成本控制和生產效率方面也面臨著挑戰。通過不斷提高生產效率、降低成本,同時保證產品品質,可以使橡膠製造廠在競爭激烈的橡膠行業中立於不敗之地。

Translation:

Keywords: Rubber products, manufacturing process, quality control

Title: Quality Control Process in Rubber Manufacturing Plant

Article: In a rubber manufacturing plant, quality control is a crucial aspect. Manufacturing rubber products requires adherence to a series of complex manufacturing processes, from the selection of raw materials to product testing, where each step must undergo strict quality control measures.

The manufacturing process of rubber products includes product design, formulation of rubber compounds, preparation of rubber materials, process control during manufacturing, and final product testing. Throughout the manufacturing process, the plant must rigorously control every detail to ensure that the product quality meets the customer's requirements.

Quality control plays a crucial role throughout the production line. From inspection of raw materials to monitoring during production, and final product testing, each step requires strict quality control. Manufacturing plants must have advanced equipment and technology to ensure effective execution of quality control during the manufacturing process.

Rubber manufacturing plants also face challenges in production capacity planning, cost control, and production efficiency. By continuously improving production efficiency, reducing costs, and ensuring product quality, rubber manufacturing plants can maintain a competitive edge in the competitive rubber industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)