在製造自行車零件的過程中,橡膠是一種常見的材料。橡膠具有耐磨的特性,非常適合用於自行車輪胎製造。製造橡膠輪胎需要考慮到輪胎壓力、胎紋設計以及輪胎尺寸等因素,以確保輪胎的耐用性和性能。製程技術和橡膠製品的設計也是至關重要的,影響著產品的品質和耐用性。

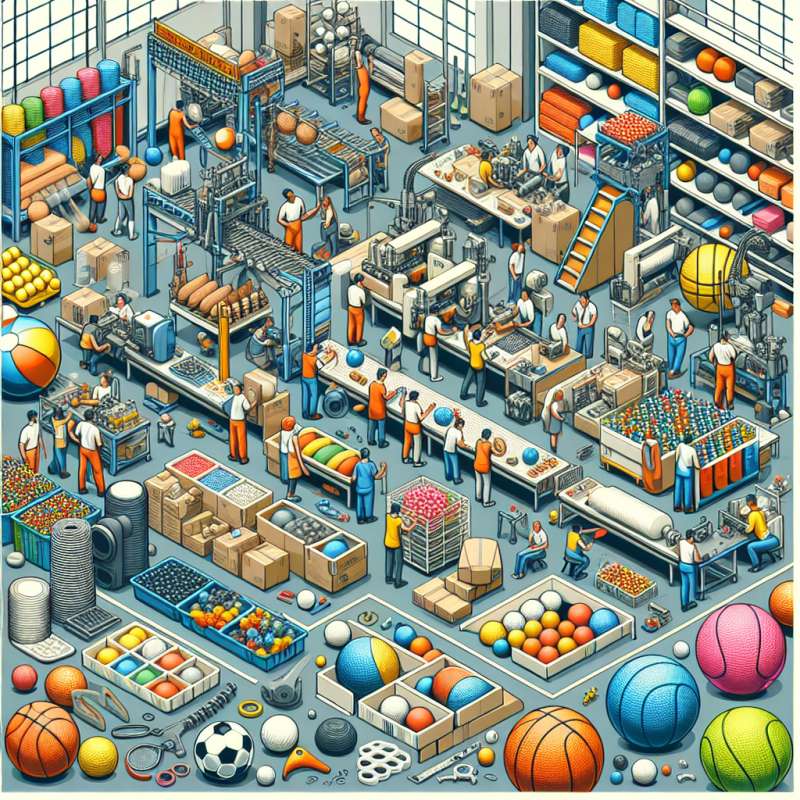

橡膠製品的製造需要先將原料進行加工,然後進行生產線的製造工藝。製造過程中需控制生產效率和成本,並重視品質控制和製品檢測。生產線上的設備和橡膠技術都是關鍵,能夠影響製造工廠的產能和產品開發。

橡膠配方和橡膠材料的選擇對製品設計和生產效率有著重要的影響。此外,橡膠加工的技術和製造工場的規劃也對產品的品質和成本控制至關重要。橡膠行業在製造工廠的產能規劃和產品開發中扮演著重要角色。

綜合以上因素,橡膠製自行車零件的生產線技術至關重要,需要重視橡膠製品的生產過程和技術,確保產品的質量和性能。

Translation:

Keywords: Rubber, Bicycle Parts, Production Line

Title: Production Line Technology of Rubber-Made Bicycle Parts

Article: Rubber is a common material used in the manufacturing of bicycle parts. Rubber is wear-resistant and is particularly suitable for making bicycle tires. When manufacturing rubber tires, factors such as tire pressure, tread design, and tire size need to be considered to ensure the durability and performance of the tires. Process technology and product design of rubber products are also crucial, affecting the quality and durability of the products.

The production of rubber products involves processing raw materials and then manufacturing processes on the production line. Controlling production efficiency and costs, and emphasizing quality control and product testing during the manufacturing process are essential. Equipment on the production line and rubber technology are critical, affecting the production capacity of manufacturing plants and product development.

The selection of rubber formulas and materials has a significant impact on product design and production efficiency. Additionally, the technology of rubber processing and the planning of manufacturing facilities are essential for product quality and cost control. The rubber industry plays a vital role in production capacity planning and product development in manufacturing plants.

Considering the factors mentioned above, the production line technology of rubber-made bicycle parts is crucial. It is essential to prioritize the production process and technology of rubber products to ensure product quality and performance.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)