木竹是一種常見的原料,可以用來製作各種製品。木竹製品的製造過程通常包括以下幾個步驟。首先,選用優質的木竹,以確保製品的質量。然後,將木竹進行加工,比如切割、削皮等,以便後續的製造工序。接著,根據製品的設計要求,進行製造和組裝。最後,進行包裝和檢驗,確保產品符合標準。

在製造過程中,製造商通常會根據客戶的需求和設計要求,製作不同種類的木竹製品,比如桌子、椅子、筷子等。這些製品不僅美觀大方,而且具有較高的耐用性和實用性,深受消費者歡迎。

總的來說,木竹製品的製造過程需要經過精心設計和嚴格控製,才能生產出高質量的產品,滿足市場需求。

Translation:

Keywords: bamboo, products, manufacturing

Title: The manufacturing process of bamboo products

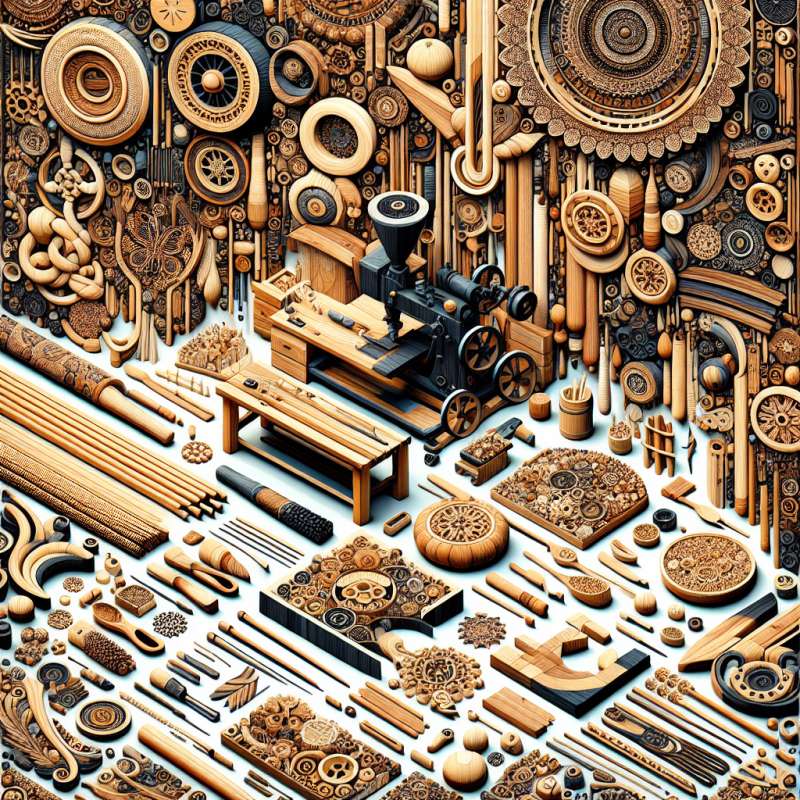

Article: Bamboo is a common raw material that can be used to make various products. The manufacturing process of bamboo products usually includes the following steps. First, select high-quality bamboo to ensure the quality of the products. Then, process the bamboo, such as cutting and peeling, for the subsequent manufacturing processes. Next, manufacture and assemble according to the design requirements of the products. Finally, package and inspect to ensure the products meet standards.

During the manufacturing process, manufacturers typically produce different types of bamboo products, such as tables, chairs, chopsticks, based on customer needs and design requirements. These products are not only aesthetically pleasing but also have high durability and practicality, making them popular among consumers.

In summary, the manufacturing process of bamboo products requires careful design and strict control to produce high-quality products that meet market demands.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)