功能性母粒是一種添加劑,能夠賦予塑膠材料特定的功能性質和改善其性能。作為未來塑膠製品製造的主要材料之一,功能性母粒在各個行業中扮演著關鍵角色。

尼龍是一種常用的塑膠材料,具有高強度、耐磨和耐腐蝕等優良特性。功能性母粒在尼龍的製造過程中被廣泛應用,能夠增強其特定的功能性能。例如,添加阻燃塑膠功能性母粒可以提高尼龍的阻燃性能,使其更適用於高安全性要求的產品製造。

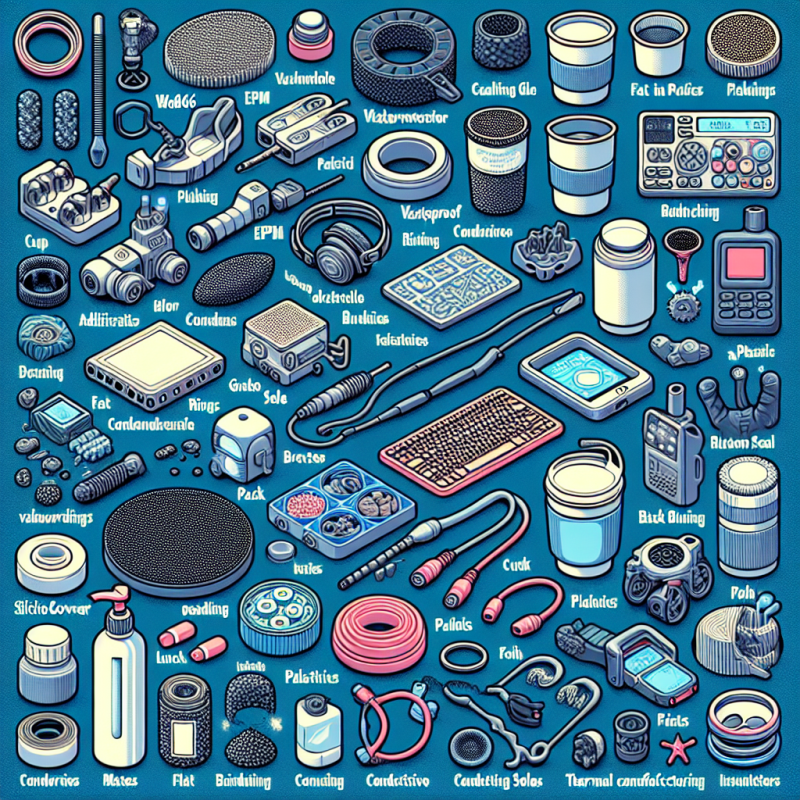

塑膠外殼及配件製造是塑膠製品製造中非常重要的一環。功能性母粒可以為塑膠外殼和配件提供多種增值功能。例如,添加導電碳黑功能性母粒可以使外殼具有導電性,用於電子產品可以防止靜電累積。同樣地,添加抗靜電塑膠功能性母粒可以有效減少靜電的產生,保護敏感電子元件。

塑膠代工是一種生產模式,即將製造過程委託給專業的製造廠商。功能性母粒在塑膠代工中有很大的應用潛力。使用功能性母粒可以有效提高產品的性能和質量,同時降低製造成本。例如,添加改性母粒可以提高塑膠的強度和硬度,增強產品的耐用性。

未來發展趨勢中,塑膠行業將持續推動功能性母粒的研發和應用。導熱塑膠功能性母粒可以提高塑膠材料的導熱性能,應用於高溫環境中的產品製造。奈米粉體功能性母粒的應用也將得到更廣泛的發展,以提高塑膠材料的機械強度和耐久性。

總結而言,功能性母粒在未來塑膠製品製造中將發揮重要作用。尼龍、塑膠外殼及配件製造、塑膠代工是其中幾個重要領域。隨著技術的不斷發展,我們可以期待更多創新的功能性母粒應用和新興的市場需求。

關鍵字: Functional masterbatch, Nylon, Plastic casing and accessories manufacturing, Plastics, Contract manufacturing

標題: The Crucial Role of Functional Masterbatch in Future Plastic Product Manufacturing

Functional masterbatch is an additive that gives plastic materials specific functional properties and improves their performance. As one of the main materials in future plastic product manufacturing, functional masterbatch plays a crucial role in various industries.

Nylon is a commonly used plastic material known for its high strength, wear resistance, and corrosion resistance. Functional masterbatch is widely used in the production of nylon to enhance its specific functional properties. For example, adding flame retardant plastic functional masterbatch can improve the flame retardancy of nylon, making it more suitable for the manufacturing of products with high safety requirements.

Plastic casing and accessories manufacturing is an essential part of plastic product manufacturing. Functional masterbatch can provide various value-added functions for plastic casings and accessories. For instance, adding conductive carbon black functional masterbatch can make the casing conductive, preventing static accumulation in electronic products. Similarly, adding anti-static plastic functional masterbatch can effectively reduce static generation, protecting sensitive electronic components.

Plastic contract manufacturing is a production model where the manufacturing process is outsourced to specialized manufacturers. Functional masterbatch has great potential in plastic contract manufacturing. Using functional masterbatch can effectively improve the performance and quality of products while reducing manufacturing costs. For example, adding modified masterbatch can enhance the strength and hardness of plastics, increasing the durability of the products.

In the future, the plastic industry will continue to drive the research, development, and application of functional masterbatch. Functional thermally conductive plastic masterbatch can improve the thermal conductivity of plastic materials, making them suitable for manufacturing products in high-temperature environments. The application of nano-powder functional masterbatch will also have a wider development to enhance the mechanical strength and durability of plastic materials.

In conclusion, functional masterbatch will play a significant role in future plastic product manufacturing. Nylon, plastic casing and accessories manufacturing, and plastic contract manufacturing are a few important areas. With the continuous advancement of technology, we can expect more innovative applications of functional masterbatch and emerging market demands.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)