金屬表面處理在汽車零件製造中扮演著非常重要的角色。表面處理是指對金屬零件的外表進行處理,以保護其表面、提升外觀和性能。常見的表面處理方法包括鍍鉻、鍍鋅、噴漆、電鍍、噴塗、噴砂、刷漆、酸洗等。

其中,鍍鉻和鍍鋅是常見的防腐蝕處理方法,能有效延長汽車零件的使用壽命。噴漆和烤漆則可以提升零件的外觀質感,增加產品的吸引力。電鍍鍍膜和磷化則可以提高金屬零件的硬度和耐磨性。

在汽車製造的過程中,金屬零件的表面處理是至關重要的一環。通過適當的表面處理,不僅能提升產品的品質和效能,還能降低零件的故障率和維護成本。因此,製造商需要精心選擇合適的表面處理方法,並對其進行嚴格的品質控制。

金屬表面處理在汽車零件製造中的重要性不可忽視,它直接影響著產品的性能和可靠性。只有通過適當的表面處理,才能確保汽車零件具有優異的品質和持久的使用壽命。

Keyword: Metal, Surface Treatment, Automotive Parts

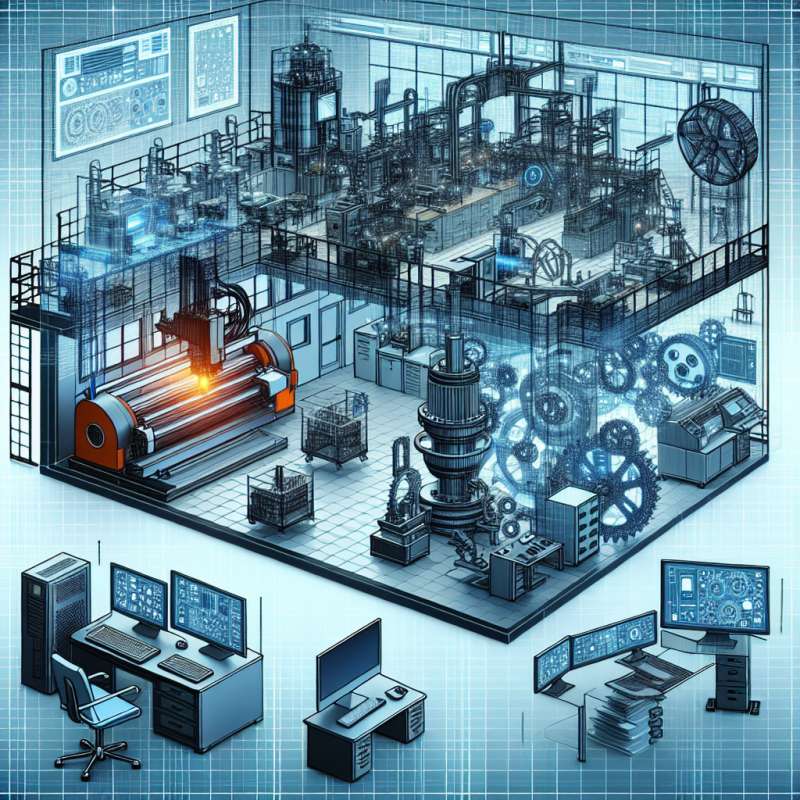

Title: The Importance of Metal Surface Treatment in Automotive Parts Manufacturing

Article: Metal surface treatment plays a crucial role in the manufacturing of automotive parts. Surface treatment refers to the process of treating the exterior of metal parts to protect the surface, enhance appearance, and improve performance. Common surface treatment methods include chrome plating, zinc plating, painting, electroplating, spray coating, sandblasting, brush painting, pickling, and more.

Chrome plating and zinc plating are commonly used corrosion protection methods that can effectively extend the lifespan of automotive parts. Painting and baking can improve the appearance and texture of the parts, increasing product attractiveness. Electroplating and phosphating can enhance the hardness and wear resistance of metal parts.

In the process of automotive manufacturing, surface treatment of metal parts is a crucial step. With proper surface treatment, product quality and performance can be enhanced, while reducing the failure rate and maintenance costs of parts. Therefore, manufacturers need to carefully select suitable surface treatment methods and implement strict quality control measures.

The importance of metal surface treatment in automotive parts manufacturing cannot be overlooked, as it directly affects the performance and reliability of the products. Only through proper surface treatment can automotive parts ensure excellent quality and durability.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)