近年來,膠材應用在各個行業中得到了廣泛的應用,其中以進口的高品質膠材為主要原料。為了提高生產效率和產品質量,許多企業紛紛引入自動化設備,以應對市場需求的增長。

在膠材應用中,攪拌脫泡是一個重要環節,影響著產品的質量和性能。自動攪拌機的應用能夠提高生產效率,降低人力成本,同時保證產品品質。進口的設計先進的攪拌脫泡設備受到了市場的廣泛關注。

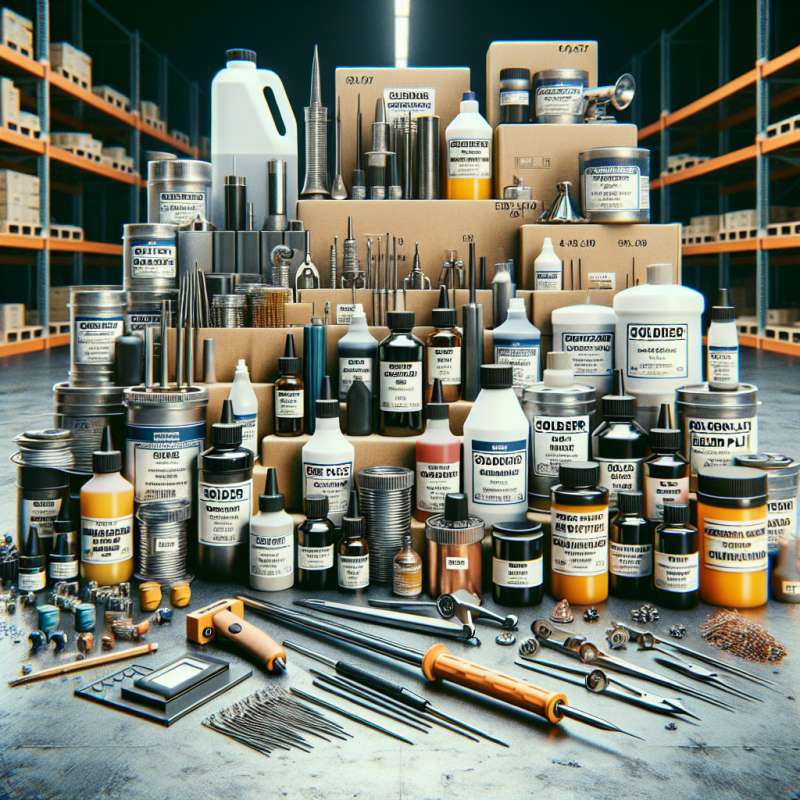

除了攪拌脫泡設備,自動化的真空系統、自動點塗膠系統也受到了廣泛的歡迎。這些設備不僅提高了生產效率,還能夠幫助企業節省人力成本,減少人為錯誤的發生。隨著市場需求的增長,自動化設備的應用將逐漸普及。

對於膠材應用行業來說,設計新穎、高效的設備將會成為市場競爭的重要因素。除了進口設備,國內企業也應該加強自主研發,提高產品的技術含量和競爭力。未來,隨著市場需求的增長,膠材應用自動化設計將會成為行業的發展趨勢。

Keywords: resin, mixing and deaeration, import, automation, design

Title: Increasing Demand for Automated Design in the Resin Application Market

Article:

In recent years, resin applications have been widely used in various industries, with high-quality imported resins as the main raw materials. To improve production efficiency and product quality, many enterprises have introduced automated equipment to meet the growing market demand.

In resin applications, mixing and deaeration is a crucial process that affects the quality and performance of products. The use of automated mixing equipment can improve production efficiency, reduce labor costs, and ensure product quality. Imported and advanced design mixing and deaeration equipment have attracted widespread attention in the market.

In addition to mixing and deaeration equipment, automated vacuum systems and automatic adhesive dispensing systems have also been widely welcomed. These equipment not only improve production efficiency but also help companies save on labor costs and reduce the occurrence of human errors. With the growing market demand, the application of automated equipment will gradually become more widespread.

For the resin application industry, the design of novel and efficient equipment will be a key factor in market competition. In addition to imported equipment, domestic enterprises should also strengthen independent research and development, improve the technical content and competitiveness of products. In the future, with the increasing market demand, the automated design of resin applications will become a trend in the industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)