預拌混凝土是一種使用原料準備好的混凝土配方,在工廠內進行製造的混凝土產品。製造預拌混凝土需要遵循嚴格的生產工藝和品質控制標準來確保產品的質量和性能。

在生產過程中,原料包括水泥、硅酸鹽、砂、石子等,必須按照混凝土配方精確搭配。生產設備包括攪拌機、傳送帶等,用來將原料混合並密實成混凝土。在製造過程中,可添加溶劑和其他添加劑以調節混凝土的特性,如強度和耐久性。

對於施工現場而言,使用預拌混凝土可以確保施工質量,並有效控制建築結構的強度和耐久性。它常應用在建築、道路、橋梁等工程中,助力工程管理與監理工作。同時,透過混凝土測試,可以評估混凝土的品質,確保施工安全和可持續性。

綜上所述,預拌混凝土生產工藝與特性對於建築領域具有重要意義,它不僅影響建築物的耐久性和結構強度,更關乎工程的施工質量和成本控制。

Keywords: Precast Concrete, Production Process, Concrete Characteristics

Title: Exploration of Precast Concrete Production Process and Characteristics

Article:

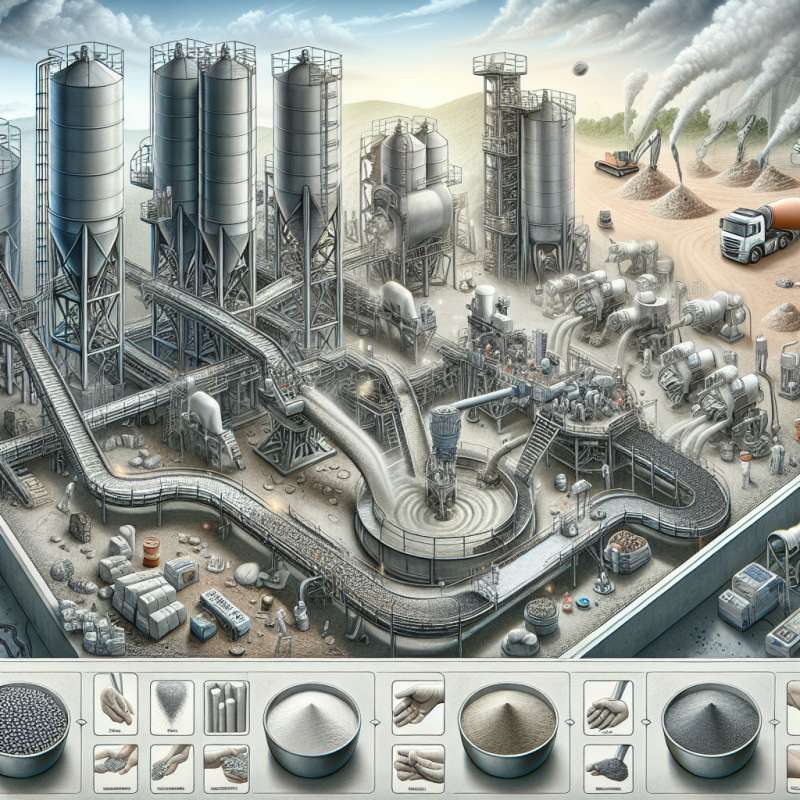

Precast concrete is a type of concrete product manufactured in factories using a pre-prepared concrete mix. The production of precast concrete requires strict adherence to production processes and quality control standards to ensure the quality and performance of the product.

During the production process, raw materials such as cement, silicates, sand, and stones need to be accurately mixed according to the concrete mix. Production equipment includes mixers, conveyors, and other equipment used to mix and compact the raw materials into concrete. Solvents and additives can be added during the manufacturing process to adjust the characteristics of the concrete, such as strength and durability.

Using precast concrete at construction sites can ensure construction quality and effectively control the strength and durability of building structures. It is commonly used in construction, road construction, bridge construction, etc., and contributes to project management and supervision. Through concrete testing, the quality of concrete can be evaluated to ensure construction safety and sustainability.

In conclusion, the production process and characteristics of precast concrete play a vital role in the construction industry. They not only affect the durability and structural strength of buildings but also impact construction quality and cost control.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)