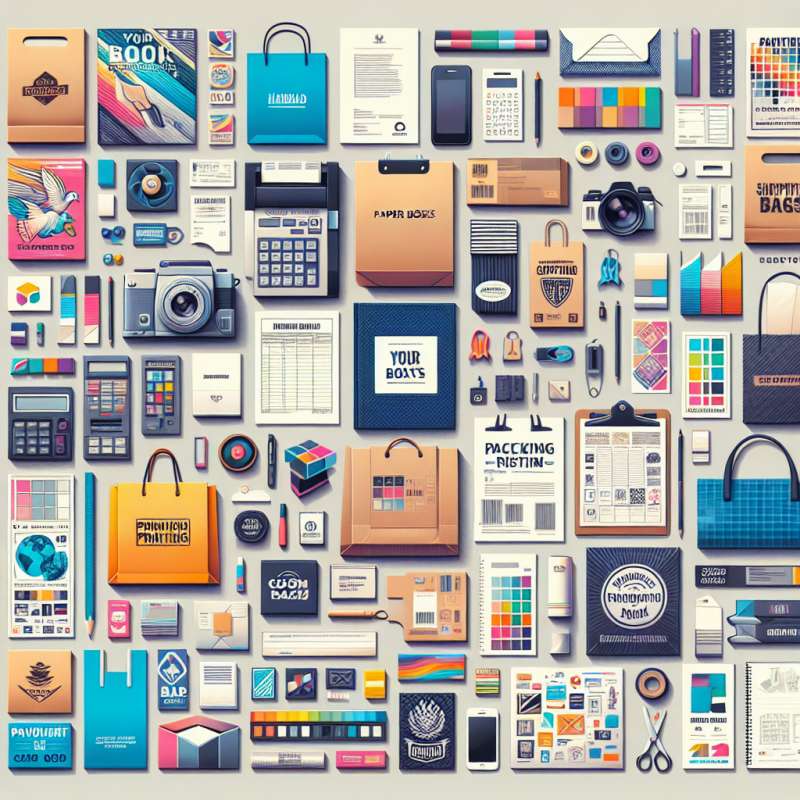

近年來,印刷產業的發展蓬勃,印刷品裝訂及加工作為印刷供應鏈中至關重要的一環,在印刷品的成品和外觀上發揮著不可或缺的作用。在這個日益競爭激烈的市場中,印刷品製作相關技術的進步和展望也成為了人們關注的焦點。以下將介紹幾個與印刷品裝訂及加工相關且具有前途的關鍵字。

首先,裝訂技術是印刷品製作過程中不可或缺的一環。傳統裝訂技術如釘裝、釘線裝訂、塑膠裝訂等在市場上廣為使用。然而,隨著數位印刷技術的發展,新的裝訂技術也逐漸崛起。例如,冷橙皮裝訂技術利用冷膠將雙頁粘接在一起,增加了出版商製作高質量書籍的能力。這些新技術優化了裝訂過程的效益和產品的品質。

其次,數位印刷技術的推出為印刷品製作帶來了巨大的變革。數位印刷技術以其快速、高效和個性化的特點,迅速在市場上得到應用。這種技術不僅可以大量打印高品質的印刷品,還可以根據個別客戶的需求定制印刷品。這種可定制性使得印刷品製作更加靈活,更符合當今個性化消費的市場需求。

再次,自動化製程也是印刷品製作的發展趨勢之一。隨著科技的進步,許多傳統製程已經可以通過機械方式自動化執行,這不僅提高了生產效率,降低了成本,同時也減少了對人工勞動力的需求。自動化製程的應用不僅可以提高生產力,還可以提高產品品質的穩定性和一致性。

最後,環保印刷是未來印刷品製作的重要方向。隨著人們對環境保護意識的提高,環保印刷已經成為印刷業的重要發展方向之一。環保印刷主要通過選擇低碳環保的印刷材料、減少印刷廢棄物的產生以及提高印刷對環境的友好性等方式實現。在未來,環保印刷將會成為消費者選擇印刷服務的重要標準之一。

總之,印刷品裝訂及加工作為印刷產業中不可或缺的一環,其未來發展的關鍵在於裝訂技術的創新、數位印刷技術的應用、自動化製程的推行和環保印刷的發展。隨著科技的不斷進步,我們相信印刷品製作將會在效率、品質和環保等方面實現更大的突破。

文章(英文):

Keywords: printing production, binding technology, digital printing, automated processes, eco-friendly printing

Title: Future Trends in Printing Binding and Processing

Article: In recent years, the printing industry has been thriving, and printing binding and processing play a crucial role in the supply chain, contributing to the final appearance and quality of printed materials. In this increasingly competitive market, the advancements and prospects of printing binding and processing technologies have become a focal point of attention. Here, we will introduce several non-regional keywords that are relevant and promising in the field of printing binding and processing.

Firstly, binding technology is an essential aspect of printing production. Traditional binding techniques, such as saddle stitching, wire binding, and plastic binding, are widely used in the market. However, with the development of digital printing technology, new binding techniques are emerging. For example, perfect binding technology utilizes cold glue to bond double pages together, enhancing publishers' ability to create high-quality books. These new techniques optimize the efficiency and quality of the binding process.

Secondly, the introduction of digital printing technology has brought significant changes to printing production. Digital printing, characterized by its speed, efficiency, and personalization, has rapidly gained popularity in the market. This technology not only enables large-scale printing of high-quality materials but also allows for customization based on individual customer needs. This level of customization makes printing production more flexible and aligns with the market demand for personalized consumption.

Furthermore, automated processes are also a trend in printing production. With technological advancements, many traditional processes can now be automated, improving production efficiency, reducing costs, and minimizing the reliance on manual labor. The application of automated processes not only increases productivity but also enhances the stability and consistency of product quality.

Lastly, eco-friendly printing is a significant direction for the future of printing production. As people's environmental consciousness grows, eco-friendly printing has become one of the important development directions in the printing industry. Eco-friendly printing is primarily achieved through the selection of low-carbon printing materials, waste reduction, and enhancing the overall environmental friendliness of printing processes. In the future, eco-friendly printing will become a vital criterion for consumers when choosing printing services.

In conclusion, printing binding and processing are indispensable aspects of the printing industry, and their future development lies in innovative binding technology, the application of digital printing, the implementation of automated processes, and the advancement of eco-friendly printing. With the continuous progress of technology, we believe that printing production will achieve significant breakthroughs in terms of efficiency, quality, and environmental sustainability.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)