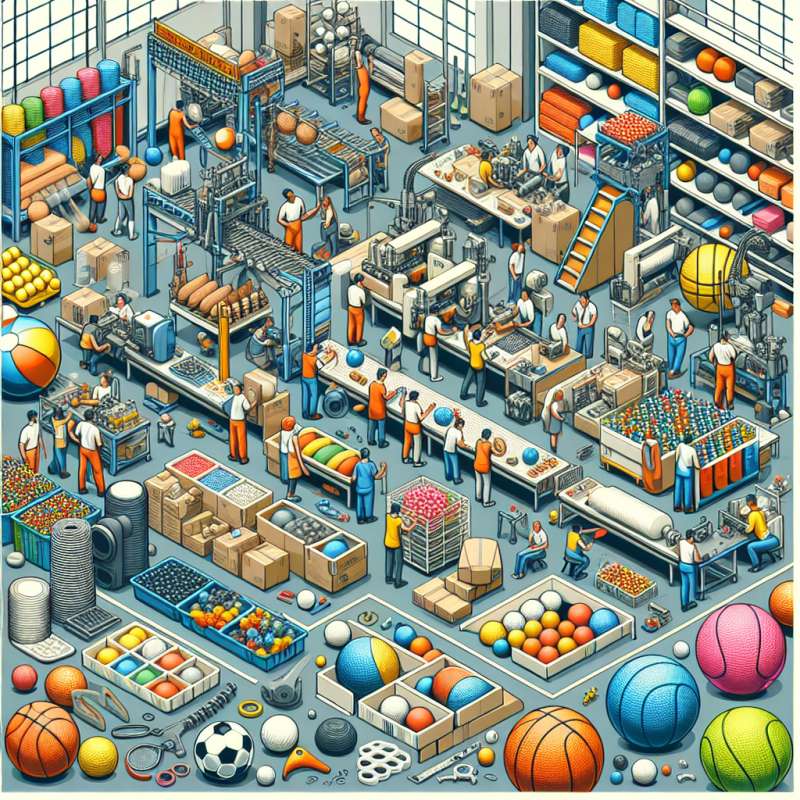

代工製造與環保設計一直以來都是金屬與橡膠製品製造業的重要關鍵。隨著科技的不斷發展,這些領域也面臨著新的挑戰和機遇。本文將探討這些關鍵趨勢以及未來發展的前景。

在金屬製品製造和橡膠製品製造領域,代工一直扮演著重要的角色。代工能夠幫助公司降低生產成本,提高生產效率,使企業專注於核心業務。然而,未來的趨勢顯示,代工不再僅僅是為了降低成本,而是注重提供高品質、高精密度的產品。精密製造技術和設備的發展,使得代工能夠生產更複雜、更精細的產品。因此,未來代工製造將更加注重設計和技術創新,以滿足不斷變化的市場需求。

另一個重要的趨勢是環保設計。隨著人們對可持續發展和環境保護意識的提高,金屬和橡膠製品製造業被迫尋找更環保的解決方案。環保設計可以幫助企業減少浪費,減少對資源的依賴,並降低對環境的負面影響。例如,采用環保材料、節能技術和循環利用設備等,可以使製造過程更加綠色和可持續。因此,環保設計將成為金屬和橡膠製品製造業的重要發展方向。

除了代工和環保設計,金屬罐製造也是一個重要的未來發展領域。金屬罐廣泛應用於食品、飲料和化妝品等行業,因其優秀的保護特性而受到廣泛青睞。未來,金屬罐製造將朝著更輕量化、更環保的方向發展。使用節能技術和環保材料,減少對自然資源的消耗,是金屬罐製造業的重要趨勢。

另外,橡膠製品製造領域也有著廣闊的未來發展空間。橡膠製品在各個行業中都起著重要作用,如汽車、電子、醫療等。近年來,隨著技術的發展,橡膠製品的性能和功能得到了大幅提升。未來的趨勢顯示,橡膠製品製造將更加注重創新設計和高性能材料的應用。同時,橡膠製品也將朝著更環保和可回收的方向發展,以減少對環境的影響。

總之,代工製造和環保設計將成為金屬和橡膠製品製造業的未來發展趨勢。這些趨勢將推動行業不斷創新,提高產品品質和生產效率,同時保護環境和提升可持續性。隨著技術的不斷進步,金屬和橡膠製品製造業將迎來更加美好和可持續的未來。

關鍵字: Manufacturing subcontracting, Design, Precision, Environmental protection, Metal product manufacturing, Metal can manufacturing, Other uncategorized rubber product manufacturing

標題: Future Trends: Subcontracting Manufacturing and Eco-Design Lead the Future of Metal and Rubber Product Manufacturing

Subcontracting manufacturing and eco-design have always played important roles in the metal and rubber product manufacturing industry. With the continuous advancement of technology, these areas also face new challenges and opportunities. This article will explore these key trends and the future prospects of the industry.

In the fields of metal product manufacturing and rubber product manufacturing, subcontracting has always been a crucial factor. Subcontracting helps companies reduce production costs and improve efficiency, allowing businesses to focus on core competencies. However, future trends indicate that subcontracting is no longer solely focused on cost reduction but emphasizes the delivery of high-quality, high-precision products. The development of precision manufacturing techniques and equipment enables subcontracting to produce more complex and intricate products. Therefore, future subcontracting manufacturing will prioritize design and technological innovation to meet the ever-changing market demands.

Another important trend is eco-design. With increasing awareness of sustainable development and environmental protection, the metal and rubber product manufacturing industry is compelled to seek more environmentally friendly solutions. Eco-design can help businesses reduce waste, decrease reliance on resources, and minimize negative environmental impacts. For instance, adopting eco-friendly materials, energy-saving technologies, and recycling equipment can make the manufacturing process greener and more sustainable. Thus, eco-design will become a significant direction for the development of the metal and rubber product manufacturing industry.

In addition to subcontracting and eco-design, metal can manufacturing is also an important area for future development. Metal cans are widely used in the food, beverage, and cosmetic industries due to their excellent protective properties. In the future, metal can manufacturing will move towards lightweight and more environmentally friendly approaches. Utilizing energy-efficient technologies and eco-friendly materials to reduce natural resource consumption is a major trend in metal can manufacturing.

Furthermore, the field of rubber product manufacturing also offers vast potential for future development. Rubber products play vital roles in various sectors such as automotive, electronics, and healthcare. In recent years, with technological advancements, rubber products have undergone significant improvements in performance and functionality. Future trends indicate that rubber product manufacturing will focus more on innovative designs and the application of high-performance materials. Simultaneously, rubber products will move towards greater environmental friendliness and recyclability to minimize environmental impact.

In conclusion, subcontracting manufacturing and eco-design will be the future trends driving the metal and rubber product manufacturing industry. These trends will spur continuous innovation, enhance product quality and production efficiency, while also preserving the environment and promoting sustainability. With the constant advancement of technology, the metal and rubber product manufacturing industry will embrace a brighter and more sustainable future.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)