鋁合金是一種輕質且具有良好耐腐蝕性能的材料,因此被廣泛應用於製造產品中。鋁合金鑄造技術作為一種重要的製造方法,能夠有效地生產各種鋁合金製品,包括鋁件製造。

鋁合金鑄造是將鋁合金材料融化後注入到模具中進行形成的製造過程。通過鑄造,可以製造出各種粗製品,如引擎零件、車身組件、航空器結構等。這些鋁合金製品都具有高強度和優異的耐磨耐腐蝕性能。

隨著科技的發展,鋁合金鑄造技術不斷進步和改進。現代的鋁合金鑄造工藝已經相當成熟,能夠生產出高精度和高性能的鋁合金製品。同時,鋁合金鑄造還可以實現工藝優化,降低製造成本,提高生產效率。

在未來,隨著對輕量化材料需求的增加,鋁合金鑄造技術將會得到更廣泛的應用和發展。作為一種綠色環保的製造方法,鋁合金鑄造將會在各個行業中發揮重要作用,推動產品的革新和進步。

Keywords: Aluminum Alloy, Casting, Aluminum Parts Manufacturing

Title: Application and Development of Aluminum Alloy Casting Technology

Article:

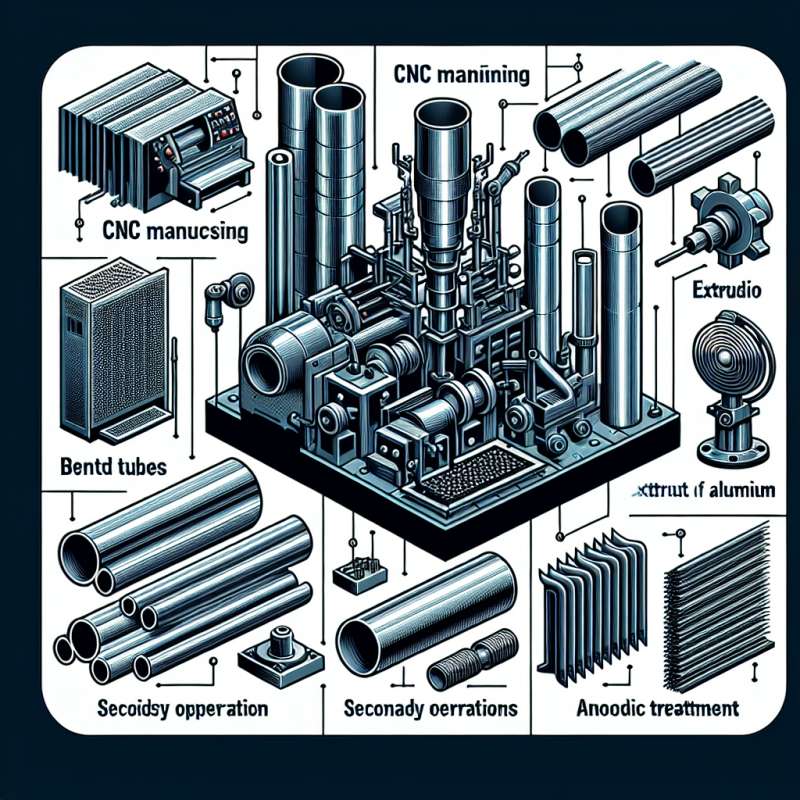

Aluminum alloy is a lightweight material with excellent corrosion resistance, making it widely used in the manufacturing of products. Aluminum alloy casting technology, as an important manufacturing method, can efficiently produce various aluminum alloy products, including aluminum parts manufacturing.

Aluminum alloy casting is a manufacturing process that involves melting aluminum alloy material and injecting it into molds for shaping. Through casting, various rough products can be produced, such as engine components, body assemblies, aircraft structures, etc. These aluminum alloy products exhibit high strength and excellent wear and corrosion resistance.

With the advancement of technology, aluminum alloy casting technology continues to progress and improve. Modern aluminum alloy casting processes are quite mature, capable of producing high-precision and high-performance aluminum alloy products. Additionally, aluminum alloy casting can achieve process optimization to reduce manufacturing costs and improve production efficiency.

In the future, with the increasing demand for lightweight materials, aluminum alloy casting technology will be more widely applied and developed. As a green and environmentally-friendly manufacturing method, aluminum alloy casting will play an important role in various industries, driving product innovation and advancement.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)