聚酯粒是製造塑膠製品的重要原料之一,其生產過程需要嚴格的品質控制。在製造過程中,首先需要確保所使用的原料符合標準,並通過檢測確保質量穩定。製程中的技術和設備也需要保持優良狀態,以確保產品質量可控。

品質控制是生產過程中至關重要的一環,可以通過嚴格的檢測來確保產品的合格率。全自動化的生產線可以提高效率,降低成本,同時提高產能,以應對市場需求的變化。

環保問題一直是塑膠製造業面臨的挑戰,然而聚酯粒的生產過程中,品質控制與環保可謂並重。透過不斷創新技術及改進製程控制,生產出優質的聚酯粒不僅讓企業擁有競爭力,同時也可保護環境。

關鍵字: Polyester granules, raw materials, quality control

Title: Quality Control in the Manufacturing Process of Polyester Granules

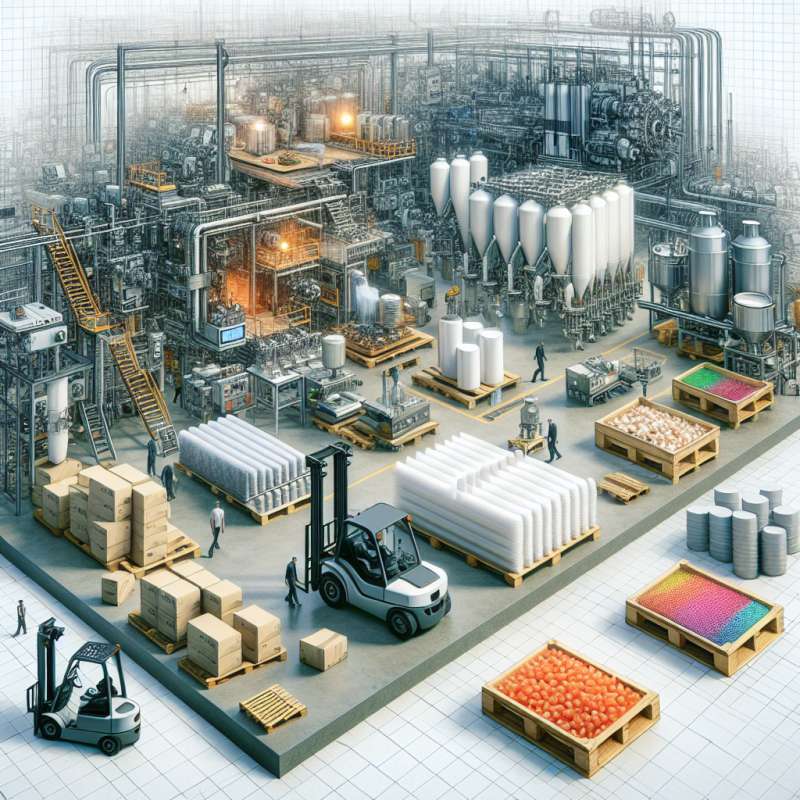

Article: Polyester granules are vital raw materials for producing plastic products, and their manufacturing process requires strict quality control. In the production process, it is essential to ensure that the materials used meet standards and undergo testing to ensure consistent quality. The technology and equipment used in the process also need to be maintained in excellent condition to ensure the controllability of product quality.

Quality control is a crucial aspect of the production process, ensuring product compliance through rigorous testing. Fully automated production lines can improve efficiency, reduce costs, and increase production capacity to meet market demand fluctuations.

Environmental concerns have always been a challenge for the plastic manufacturing industry. However, in the production process of polyester granules, quality control and environmental protection are equally critical. Through innovative technologies and improved process control, producing high-quality polyester granules not only enhances a company's competitive edge but also protects the environment.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)