近年來,電子產業的蓬勃發展催生了許多相關產業的興起,其中包括電腦週邊設備製造。許多公司開始專注於設計和製造各種電子產品,以滿足市場對於科技產品的需求。

電子產業的發展過程中,許多企業也開始尋找更有效的生產方式,其中一種方法是將加工和製造工作外包給代工廠。透過代工廠的幫助,企業可以更專注於產品設計和市場推廣,同時也能夠節省成本和時間。

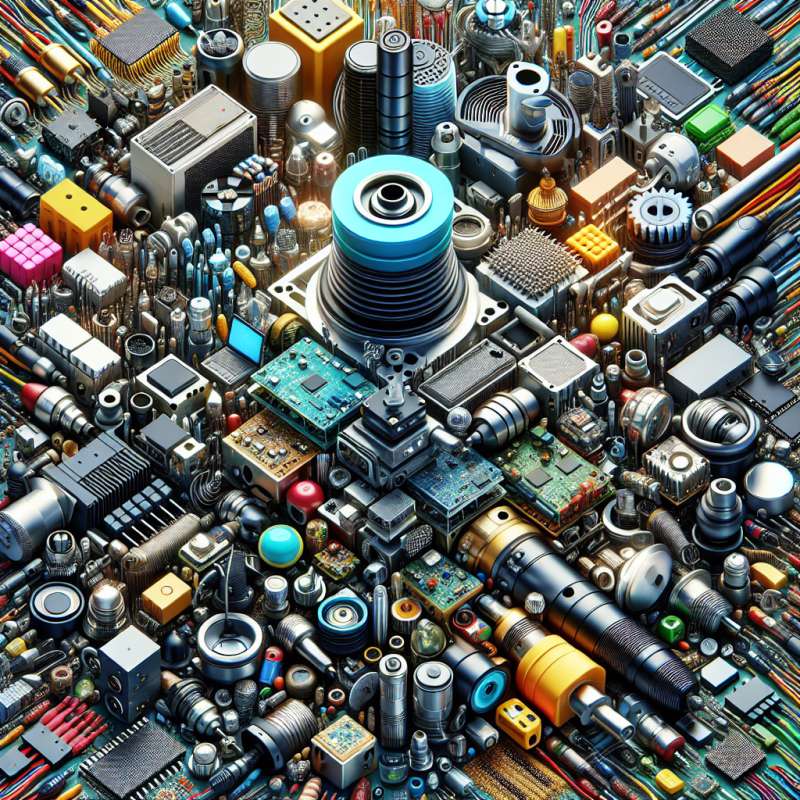

電子產業中常見的製造過程包括印刷電路板組件製造和通用機械設備製造。這些製造過程需要使用各種零件和材料,如線材、絕緣材料、端子等。另外,在電子產品的製造過程中,接頭和膠套也是不可或缺的元件。

多數大型電子公司通常設置專門的事業部來負責生產和製造,專注於產品的研發和生產流程。未來,隨著科技的不斷進步和市場的快速變化,電子設備製造業將需要不斷創新和升級,以滿足消費者對於更先進產品的需求。

Keywords: electronics, computer peripheral equipment manufacturing, business unit

Title: Future Trends in Electronics Manufacturing Industry

Article: In recent years, the rapid development of the electronics industry has led to the rise of many related industries, including computer peripheral equipment manufacturing. Many companies have started focusing on designing and producing various electronic products to meet the market demand for technology products.

During the development of the electronics industry, many enterprises have also started seeking more efficient manufacturing methods, one of which is outsourcing processing and manufacturing work to contract manufacturers. With the help of contract manufacturers, companies can focus more on product design and marketing, while also saving costs and time.

Common manufacturing processes in the electronics industry include printed circuit board assembly manufacturing and general machinery equipment manufacturing. These manufacturing processes require the use of various parts and materials such as wiring, insulation materials, and terminals. Additionally, connectors and protective sleeves are also essential components in the manufacturing process of electronic products.

Most large electronics companies typically establish dedicated business units to handle production and manufacturing, focusing on product research and production processes. In the future, with the continuous advancement of technology and rapid market changes, the electronics manufacturing industry will need to constantly innovate and upgrade to meet consumer demand for more advanced products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)