冶金工藝是指將礦石加工成鋼鐵的過程,其中包含了製鐵、熔煉、煉鋼等步驟。在鋼鐵生產過程中,表面處理是至關重要的一環,透過不同的技術能提升鋼材的質量與功能性。其中,鍍鋅技術是一種常見的表面處理方式之一。

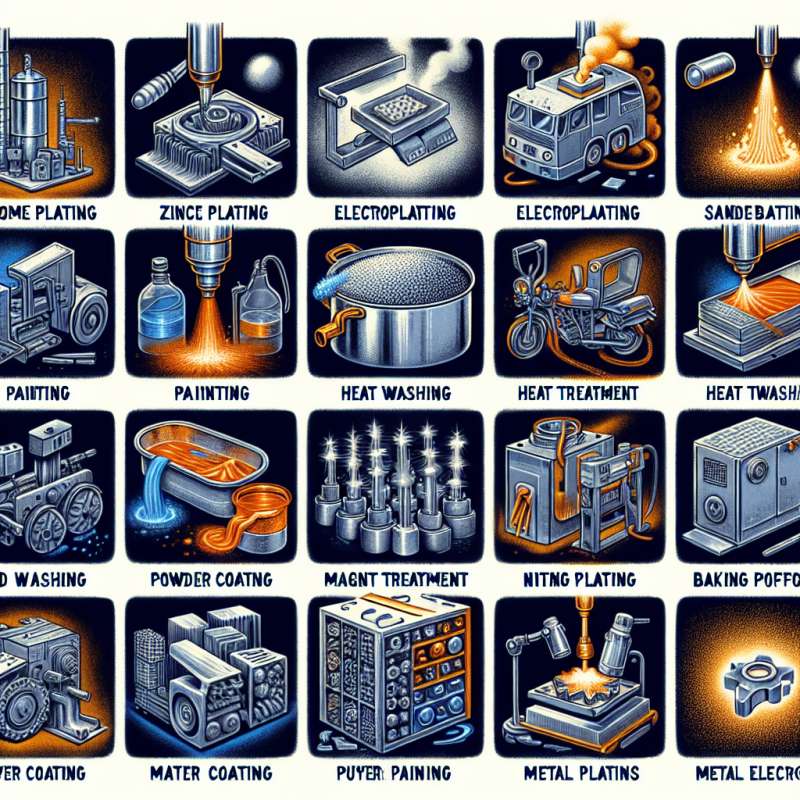

鍍鋅是將鋅層附著在鋼材表面的過程,這能有效防止鋼材受到銹蝕的侵蝕,延長其壽命。鍍鋅還能提高鋼材的耐腐蝕性能,使其適用於更廣泛的應用場景中。除了鍍鋅外,還有許多其他表面處理技術,如塗層、電鍍、熱處理等,都對鋼材的性能有著重要影響。

在製造過程中,鋼材的表面處理不僅影響著產品的外觀質量,更直接關係到其使用壽命和效能。因此,冶金工藝中的表面處理技術不容忽視,對於提升產品質量和市場競爭力至關重要。

Key words: Metallurgical technology, Surface treatment, Galvanizing

Title: Surface treatment and galvanizing technology in metallurgical process

Article: Metallurgical technology refers to the process of processing ore into steel, which includes steps such as ironmaking, smelting, and steelmaking. In the production process of steel, surface treatment is a crucial aspect that can enhance the quality and functionality of steel materials. Amongst various techniques, galvanizing is a common surface treatment method.

Galvanizing involves coating steel surfaces with a layer of zinc, effectively preventing corrosion and extending the lifespan of the steel. Galvanizing also enhances the corrosion resistance of steel, making it suitable for a wider range of applications. Apart from galvanizing, there are many other surface treatment technologies, such as coating, electroplating, heat treatment, etc., which significantly impact the performance of steel materials.

During the manufacturing process, surface treatment of steel materials not only affects the appearance quality of the products but also directly influences their lifespan and performance. Therefore, surface treatment technologies in metallurgical processes are crucial for enhancing product quality and market competitiveness.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)