化學原材料在製造塑膠日用品時扮演著重要的角色。為了確保生產線的順利運作,進貨及倉儲管理變得至關重要。在進貨過程中,要做好供應商的評估工作,確保所購買的原材料符合質量要求。同時,在倉儲管理方面,要注意庫存控制和貨物管理的效率,確保原材料能夠及時供應給生產線。

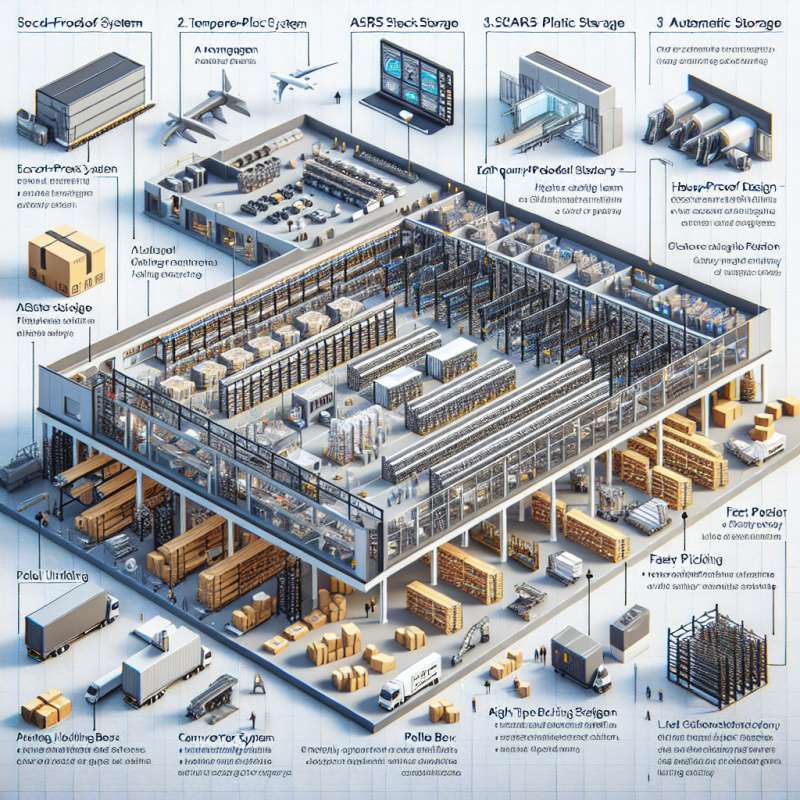

倉儲的安排也是很重要的,不同類型的化學原材料需要存放在不同的地方,以免產生危險。在倉庫管理方面,要精心設計倉庫的配置,包括貨架管理和庫位分配,以提高儲存效率並確保安全。倉庫管理也需要對設備進行定期的維護和管理,以確保作業的正常運轉。

透過進貨和倉儲管理的優化,不僅可以提高生產效率,還可以更好地控制成本。更重要的是,這些管理措施還可以幫助企業預測需求,提前進行進貨計劃,以應對市場變化帶來的挑戰。

Keyword: Chemical Raw Materials, Procurement, Warehousing

Title: Procurement and Warehousing Management of Chemical Raw Materials

Article:

Chemical raw materials play a vital role in the production of plastic daily necessities. To ensure the smooth operation of the production line, procurement and warehousing management become crucial. During the procurement process, it is important to evaluate suppliers to ensure the purchased raw materials meet quality requirements. At the same time, in warehousing management, attention should be paid to inventory control and the efficiency of goods management to ensure timely supply of raw materials to the production line.

The arrangement of warehouses is also important, as different types of chemical raw materials need to be stored in different places to prevent hazards. In warehouse management, careful design of warehouse configuration, including shelf management and warehouse space allocation, is necessary to improve storage efficiency and ensure safety. Warehouse management also requires regular maintenance and management of equipment to ensure the normal operation of operations.

By optimizing procurement and warehouse management, not only can production efficiency be improved, but costs can also be better controlled. More importantly, these management measures can help companies predict demand, plan for procurement in advance to address challenges brought by market changes.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)