在橡膠製造業中,製造工藝和產能規劃是非常重要的關鍵。橡膠製品通常是利用橡膠材料進行加工和製造而成的。製造工藝包括了設計製品、選擇適當的橡膠配方、製程控制、品質檢測等,可以影響產品的生產效率和品質控制。而產能規劃則是評估生產線的產能,確保生產能力與市場需求相符,並做出相應的投資與調整。

橡膠製品的製造工藝是一個複雜的過程,需要充分考慮原料的選擇、製品設計的合理性、生產線設備的配備等因素。在生產過程中,橡膠技術和橡膠加工的專業知識至關重要,以確保製品符合標準和客戶需求。同時,成本控制也是製造過程中需要特別關注的一點,通過提高生產效率和優化製造工藝,可以降低生產成本,提高競爭力。

在橡膠行業中,有效的產能規劃是保障生產持續穩定的重要措施。通過分析市場需求、監控生產進度、優化生產線配置等方式,可以確保產品開發和生產過程的順利進行。合理的產能規劃也可以避免生產過程中因為生產能力不足而導致的損失,同時提高生產效率和產品質量。

關鍵字: Rubber products, Manufacturing process, Production capacity planning

Title: Manufacturing Process and Production Capacity Planning in Rubber Manufacturing

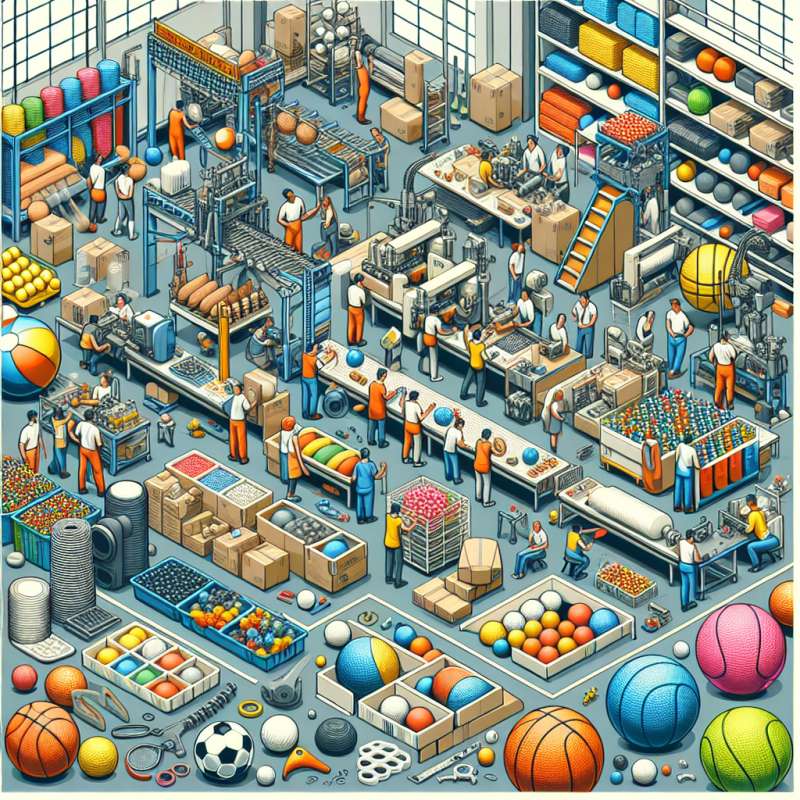

Article: In the rubber manufacturing industry, the manufacturing process and production capacity planning are crucial keys. Rubber products are typically processed and manufactured using rubber materials. The manufacturing process involves designing products, selecting appropriate rubber formulations, process control, quality testing, etc., which can affect production efficiency and quality control. Production capacity planning evaluates the production capacity of production lines, ensuring that production capabilities align with market demand and making appropriate investments and adjustments.

The manufacturing process of rubber products is a complex one, requiring careful consideration of factors such as material selection, product design rationality, and equipment configuration. In the production process, expertise in rubber technology and rubber processing is crucial to ensure that products meet standards and customer requirements. Cost control is also a key focus in the manufacturing process. By improving production efficiency and optimizing manufacturing processes, production costs can be reduced, and competitiveness enhanced.

In the rubber industry, effective production capacity planning is crucial to ensuring stable and continuous production. By analyzing market demand, monitoring production progress, and optimizing production line configurations, product development and production processes can proceed smoothly. Reasonable production capacity planning can also prevent losses due to insufficient production capacity and improve production efficiency and product quality.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)