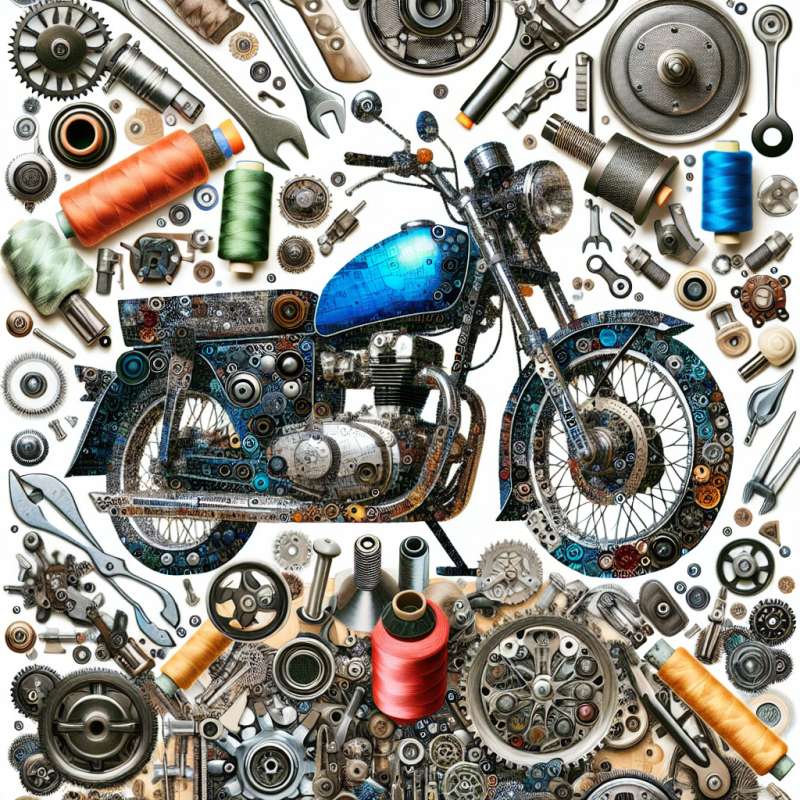

在螺絲及螺帽製造業中,染紗零件與客制化製程正扮演著越來越重要的角色。這些技術的發展不僅改善了製造過程的效率,同時也提升了產品的品質和彈性。

染紗零件是指在染布機械零件製造過程中使用的特殊材料。它們通常由耐磨耗且具有高強度的材料製成,以應對頻繁且高速的運轉環境。隨著紡織行業的快速發展,對於染布機械零件的需求也在不斷增加。未來,我們可以預見到染紗零件將會更加輕量化且具有更長的使用壽命,以滿足紡織行業對於高效率和持久性的需求。

客制化製程是在螺絲及螺帽製造過程中的另一個重要趨勢。隨著工業發展的要求愈趨多元化,客戶對於特定規格和功能需求的螺絲及螺帽也越來越高。客制化製程可以根據客戶的需求,生產出符合其特定要求的螺絲及螺帽。這項技術的發展將解決通用型螺絲及螺帽無法滿足的特殊需求,並提供更好的產品適應性和性能。

除了染紗零件和客制化製程外,螺絲及螺帽製造業還受到其他關鍵技術的影響。氬銲、沖床和車床等機械製造技術在製造過程中發揮著重要的作用。使用氬銲技術可以提高焊接效果和接合強度,增加生產效率。沖床和車床則在螺絲及螺帽的製造零件加工過程中扮演著重要的角色。隨著科技的進步,這些技術將會更加先進和自動化,進一步提高產品的品質和生產效率。

總結而言,染紗零件和客制化製程在螺絲及螺帽製造業中具有重要意義且有著很大的發展潛力。隨著紡織機械設備製造和螺絲、螺帽及鉚釘製造行業的不斷發展,我們可以預見到這些關鍵技術將會逐漸進步,以滿足快速變化和不斷增長的市場需求。

關鍵字: Dyeing Parts, Customization, Screw and Bolt Manufacturing

標題: The Future Development Trends of Dyeing Parts and Customization in Screw and Bolt Manufacturing Industry

In the screw and bolt manufacturing industry, dyeing parts and customization processes are playing an increasingly important role. The development of these technologies not only improves the efficiency of the manufacturing process but also enhances the quality and flexibility of the products.

Dyeing parts refer to special materials used in the production of dyeing machine parts. They are usually made of wear-resistant and high-strength materials to withstand frequent and high-speed operations. With the rapid development of the textile industry, the demand for dyeing machine parts is also increasing. In the future, we can expect that dyeing parts will become lighter and have longer service life to meet the textile industry's requirements for high efficiency and durability.

Customization processes are another significant trend in screw and bolt manufacturing. With the increasing diversity of industrial development, customers have higher demands for screws and bolts with specific specifications and functional requirements. Customization processes can produce screws and bolts that meet the specific requirements of customers. This technology will address the special needs that cannot be met by standard screws and bolts, providing better product adaptability and performance.

In addition to dyeing parts and customization processes, the screw and bolt manufacturing industry is also influenced by other key technologies. Argon welding, punching machines, and lathes play important roles in the manufacturing process. Using argon welding technology can improve welding efficiency and joint strength, increasing production efficiency. Punching machines and lathes are crucial in the manufacturing process of screw and bolt components. With the advancement of technology, these techniques will become more advanced and automated, further improving product quality and production efficiency.

In conclusion, dyeing parts and customization processes have significant importance and great development potential in the screw and bolt manufacturing industry. With the continuous development of textile machinery manufacturing and screw, bolt, and rivet manufacturing industries, these key technologies are expected to progress gradually to meet the rapidly changing and growing market demands.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)