近年來,隨著科技的發展,濕製程技術在塑膠外殼及配件製造領域中扮演著舉足輕重的角色。濕製程是一種利用液體溶液和溶劑將材料塗布或浸泡在基材上的製程,透過適當的處理形成所需的產品。

在塑膠外殼製造中,濕製程能夠提供高度的精密度和表面光滑度,使得最終產品外觀更為美觀且質感較佳。同時,濕製程也可實現多種特殊效果,如防水、防潮、耐磨等功能,使產品更能符合客戶的需求。

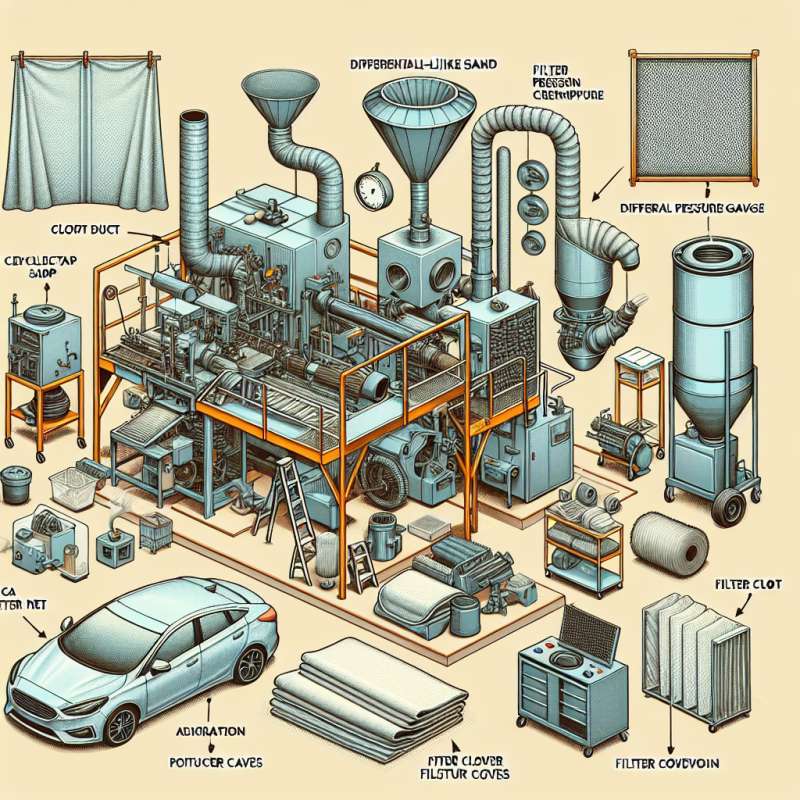

除了應用於塑膠外殼製造外,濕製程同樣廣泛運用於其他產業,如管路工程、污染防治設備製造等領域。濕製程設備維修也變得至關重要,以確保製程的穩定運行和產品品質的穩定性。

總括而言,濕製程技術在塑膠外殼製造中的應用是不可或缺的。它不僅提升了產品的質量和效率,也為相關產業帶來了更多的發展機遇。

English Translation:

Keywords: Wet Process, Wet Process Equipment, Plastic Shell and Parts Manufacturing

Title: Application of Wet Process Technology in Plastic Shell Manufacturing

Article: In recent years, with the advancement of technology, wet process technology plays a crucial role in the manufacturing of plastic shells and parts. The wet process is a process that involves coating or immersing materials in a liquid solution and solvent on a substrate to form the desired product through appropriate treatment.

In plastic shell manufacturing, wet process offers high precision and surface smoothness, resulting in more aesthetically pleasing and higher-quality final products. Additionally, wet process can achieve various special effects such as waterproofing, moisture resistance, and wear resistance, making the products better cater to customers' needs.

Apart from being applied in plastic shell manufacturing, wet process is also widely used in other industries such as pipeline engineering, pollution control equipment manufacturing, and more. Maintenance of wet process equipment has become crucial to ensure the stable operation of the process and the consistency of product quality.

In conclusion, the application of wet process technology in plastic shell manufacturing is indispensable. It not only enhances the quality and efficiency of products but also brings more development opportunities to related industries.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)