隨著科技的進步和市場需求的不斷變化,模具製造行業也在不斷發展。3D列印技術的應用為模具製造帶來了革命性的變化,不再需要傳統的木模或鋼模,而是可以通過CNC機械直接製造出精確的模具。這不僅提高了製造效率,還減少了製造成本。

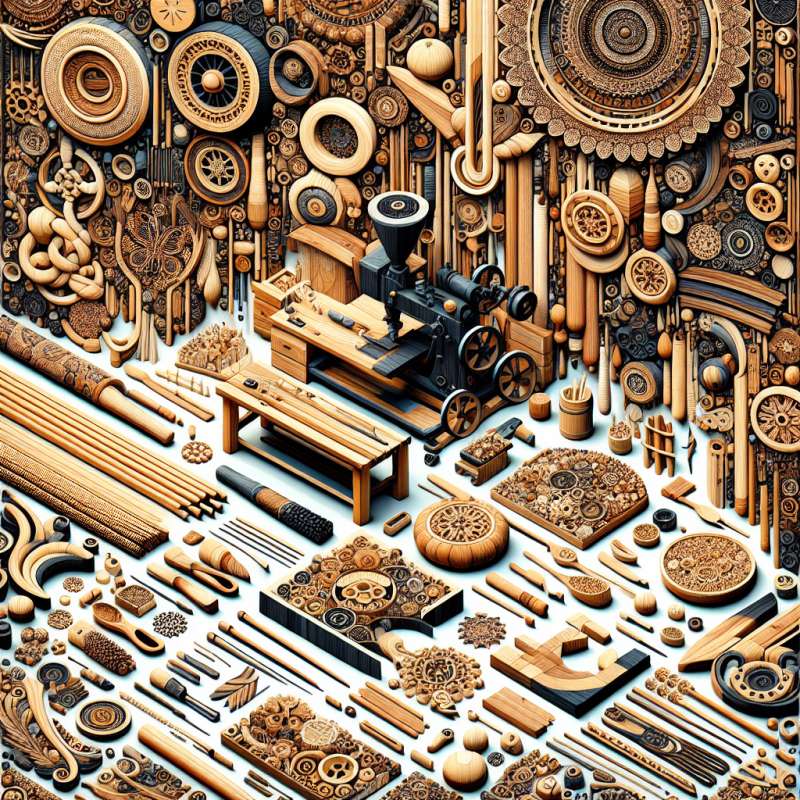

工業設計在模具製造過程中起著至關重要的作用,通過設計優化可以提高模具的壽命和生產效率。同時,木模作為一種傳統的模具製造材料,在現代工業設計中仍然占有一席之地。木模因其質地較輕,加工容易,成本低廉,適用於許多複雜形狀的模具製造。

未來模具製造行業將繼續向數碼化、智能化和自動化方向發展,通過3D列印技術和CNC機械的結合,可以實現快速、精確地製造出各種複雜形狀的模具。同時,工業設計將更加重視模具製造過程中的使用性和可持續性,以確保模具在生產中的高效運作。

未來模具製造行業的發展充滿潛力,隨著技術的不斷創新和應用,我們有信心能夠看到更多更先進的模具製造技術和產品的誕生。

Keyword: Mold, 3D, Industrial Design, CNC, Wooden Mold

Title: Future Trends in Mold Manufacturing

Article: With the advancement of technology and the constantly changing market demands, the mold manufacturing industry is also evolving. The application of 3D printing technology has brought revolutionary changes to mold manufacturing, eliminating the need for traditional wooden or steel molds and allowing for precise molds to be produced directly through CNC machinery. This not only increases manufacturing efficiency but also reduces production costs.

Industrial design plays a crucial role in the mold manufacturing process, as design optimization can improve mold lifespan and production efficiency. Additionally, wooden molds, as a traditional mold manufacturing material, still hold a place in modern industrial design. Wooden molds are lightweight, easy to process, and cost-effective, making them suitable for manufacturing many complex-shaped molds.

The future of the mold manufacturing industry will continue to develop towards digitization, intelligence, and automation. The combination of 3D printing technology and CNC machinery will enable the rapid and accurate production of various complex-shaped molds. Furthermore, industrial design will focus more on usability and sustainability in the mold manufacturing process to ensure efficient operation during production.

The future of the mold manufacturing industry is full of potential, and with continuous technological innovation and application, we are confident that we will see more advanced mold manufacturing technologies and products emerge.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)