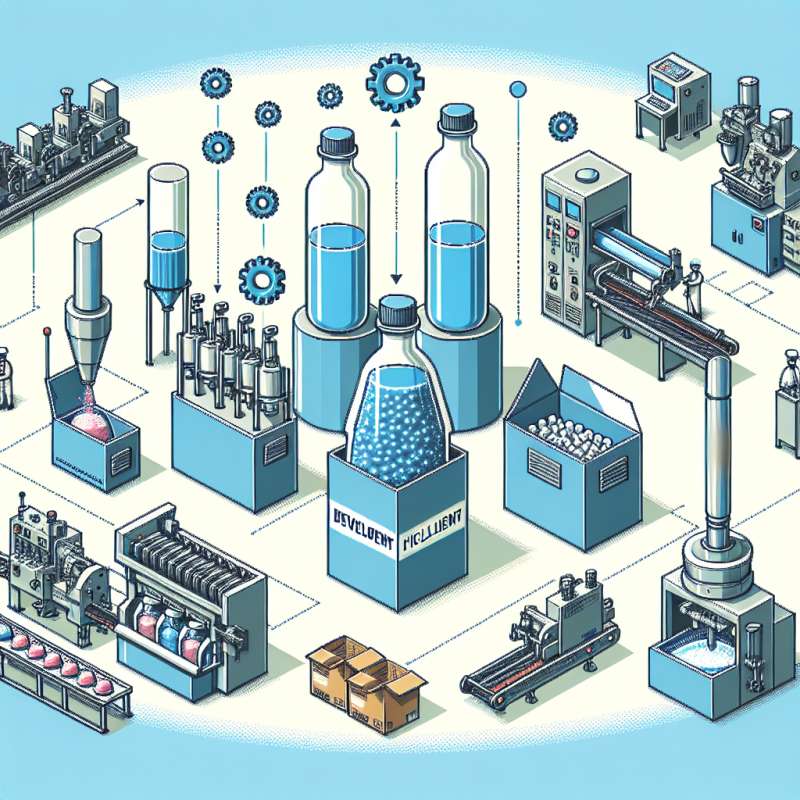

隨著科技的進步和全球經濟的發展,化學產業成為全球經濟中重要的一環。在化學產業中,錠劑、矽膠、控制、包裝等技術是不可或缺的,而相關的機械和工程技術也扮演著重要的角色。未來,化學產業製造技術將繼續進步和創新,以滿足市場和消費者的需求。

在錠劑製造方面,技術的發展將專注於提高生產效率和品質控制。現代化的製藥設備,如高速壓片機和藥片包覆機,將大大提高錠劑生產的速度和精度,同時減少了生產過程中的浪費。而對於錠劑的包裝,也將結合自動化技術和智能控制系統,實現高效率、精確度高的包裝和標識。

矽膠的應用在各個領域中都有所增加,從日常生活用品到醫療器械都有廣泛的應用。未來,矽膠製造技術將更加注重環保和可持續發展。例如,研發出更節能的生產工藝,減少對環境的影響,同時開發更多可回收和再利用的矽膠材料。

控制技術是現代工業中不可或缺的一環,尤其是在化工機械設備製造中。未來,隨著工業自動化水平的提高,控制系統將更加智能化和高效化。這將使得化工機械設備的監控和操作更加容易,並具有更高的安全性。同時,控制技術的發展也將促進化工生產的節能和減排。

包裝在化學產業中有著重要的地位。未來,包裝技術將更加專注於保護產品質量和提高運輸效率。例如,將開發出更耐用和環保的包裝材料,以延長產品的保存期限,同時減少對環境的影響。此外,智能包裝技術也將進一步發展,實現產品的追蹤和溯源,為消費者提供更多的信息和保障。

總之,未來化學產業製造技術的發展將朝著提高生產效率、環保和智慧化的方向前進。錠劑、矽膠、控制、包裝等關鍵技術將在這個過程中發揮重要作用,為化學產業的發展奠定基礎。

關鍵字:tablet, silicone gel, control, packaging, machinery, steel smelting, chemical machinery manufacturing

標題:Future Trends in Chemical Industry Manufacturing Technology

With the advancement of technology and global economic development, the chemical industry has become an important part of the global economy. In the chemical industry, technologies such as tablet manufacturing, silicone gel production, control systems, and packaging play crucial roles, and related machinery and engineering technologies are also essential. In the future, chemical industry manufacturing technology will continue to progress and innovate to meet market and consumer demands.

In terms of tablet manufacturing, the focus of technological development will be on improving production efficiency and quality control. Modern pharmaceutical equipment, such as high-speed tablet presses and coating machines, will greatly enhance the speed and accuracy of tablet production while reducing waste during the manufacturing process. In the field of tablet packaging, automation technology and intelligent control systems will be integrated to achieve efficient and precise packaging and labeling.

The application of silicone gel has been increasing in various fields, from everyday products to medical devices. In the future, the manufacturing technology of silicone gel will emphasize environmental protection and sustainable development. For example, more energy-efficient production processes will be developed to reduce environmental impact, while more recyclable and reusable silicone gel materials will be explored.

Control technology is an indispensable part of modern industry, especially in the manufacturing of chemical machinery equipment. In the future, with the improvement of industrial automation level, control systems will become more intelligent and efficient. This will make monitoring and operation of chemical machinery equipment easier and safer. Furthermore, the development of control technology will promote energy saving and emission reduction in chemical production.

Packaging plays a significant role in the chemical industry. In the future, packaging technology will focus more on product quality protection and transportation efficiency improvement. For instance, more durable and environmentally friendly packaging materials will be developed to extend the shelf life of products while reducing environmental impact. Additionally, smart packaging technology will further advance to enable product tracking and traceability, providing consumers with more information and assurance.

In conclusion, future developments in chemical industry manufacturing technology will focus on improving production efficiency, environmental friendliness, and intelligence. Key technologies such as tablet manufacturing, silicone gel production, control systems, and packaging will play vital roles in establishing the foundations for the development of the chemical industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)