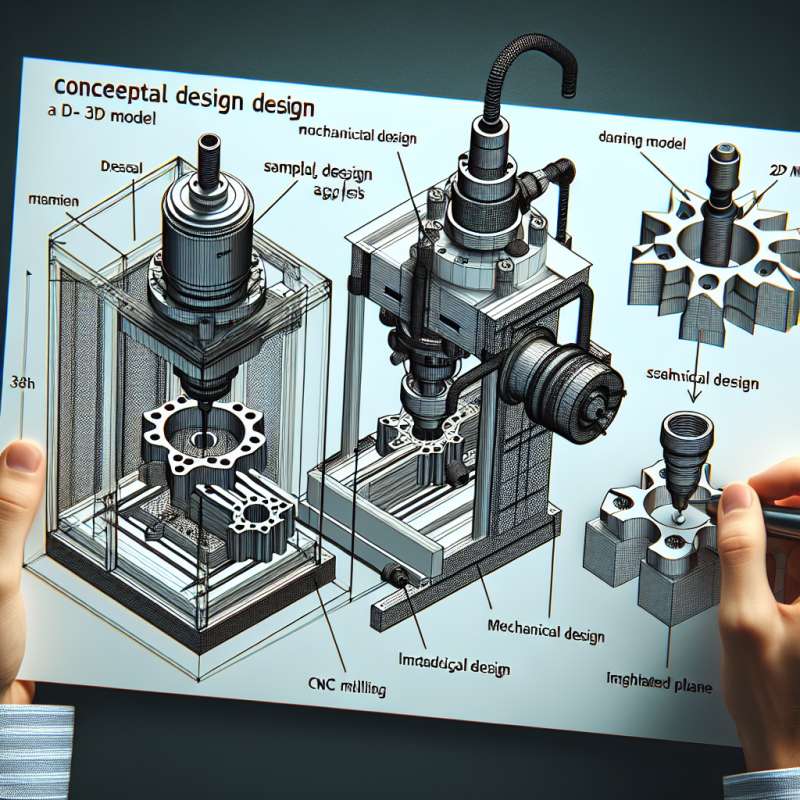

近年來,CNC技術在陶瓷製造業中扮演著關鍵角色。CNC(Computer Numerical Control)是一種透過電腦控制機械工具的技術,它可以精確地控制機器的運動,從而實現高效率的生產過程。

陶瓷產業一直是台灣的優勢產業之一。然而,傳統的陶瓷製造過程存在一些問題,例如生產效率低,產品品質難以保證等。這些問題促使業界開始尋找可以改進生產過程的技術。

為了提高生產效率和降低生產成本,設計和製造公司不斷導入CNC技術。CNC技術可以實現高度自動化的製造過程,從而提高生產效率。通過CNC技術,陶瓷產品的設計和生產過程也變得更加靈活和精確。

此外,研磨技術也在陶瓷製造業中扮演著重要角色。研磨是陶瓷加工過程中必不可少的步驟,它可以改善陶瓷表面的光滑度和精度。隨著研磨技術的不斷發展,陶瓷產品的品質和外觀也得到了顯著提升。

未來,陶瓷產業將繼續面臨著設計和機械製造方面的挑戰。隨著科技的不斷進步,設計和製造公司需要不斷創新和改進技術,以滿足市場的需求和變化。同時,隨著市場對陶瓷產品品質的要求日益提高,陶瓷製造業也需要關注品質控制和測試等方面的技術。

除了陶瓷產業,CNC技術和研磨技術在其他機械製造領域也得到了廣泛應用。例如,CNC技術可以應用於汽車和航空航天等行業的零部件加工,從而提高產品的精度和可靠性。研磨技術則可以應用於高精度工具和元件的製造。這些應用將進一步推動CNC技術和研磨技術的發展。

關鍵字: CNC, ceramics, design, machinery, grinding

標題: The Future Development Trends of CNC Technology in the Ceramics Industry

In recent years, CNC technology has played a crucial role in the ceramics manufacturing industry. CNC (Computer Numerical Control) is a technology that utilizes computer control to operate machinery, enabling precise control of machine movements and achieving high efficiency production processes.

Ceramics industry has long been one of Taiwan's key industries. However, traditional ceramics manufacturing processes have encountered certain challenges such as low production efficiency and difficulties in ensuring product quality. These issues have prompted the industry to seek out technologies that can enhance the production process.

To improve production efficiency and lower production costs, design and manufacturing companies have been incorporating CNC technology. CNC technology enables highly automated manufacturing processes, thereby enhancing production efficiency. Through CNC technology, the design and production processes of ceramics products have also become more flexible and precise.

Furthermore, grinding technology plays a significant role in ceramics manufacturing. Grinding is an essential step in the ceramics processing, improving the smoothness and accuracy of ceramic surfaces. With the continuous development of grinding technology, the quality and appearance of ceramics products have significantly improved.

In the future, the ceramics industry will continue to face challenges in design and machinery manufacturing. With advancing technology, design and manufacturing companies need to continually innovate and improve their techniques to meet market demands and changes. Simultaneously, as market demands for ceramic product quality continue to rise, the ceramics manufacturing industry should focus on quality control and testing technologies.

Aside from the ceramics industry, CNC technology and grinding technology have found wide applications in other machinery manufacturing domains. For instance, CNC technology can be applied in the production of components for industries such as automotive and aerospace, enhancing product precision and reliability. Grinding technology, on the other hand, can be employed in the manufacturing of high-precision tools and components. These applications will further drive the development of CNC technology and grinding technology.

Keyword: CNC, ceramics, design, machinery, grinding

Title: The Future Development Trends of CNC Technology in the Ceramics Industry

Article: In recent years, CNC technology has played a crucial role in the ceramics manufacturing industry. CNC (Computer Numerical Control) is a technology that utilizes computer control to operate machinery, enabling precise control of machine movements and achieving high efficiency production processes.

The ceramics industry has long been one of Taiwan's key industries. However, traditional ceramics manufacturing processes have encountered certain challenges such as low production efficiency and difficulties in ensuring product quality. These issues have prompted the industry to seek out technologies that can enhance the production process.

To improve production efficiency and lower production costs, design and manufacturing companies have been incorporating CNC technology. CNC technology enables highly automated manufacturing processes, thereby enhancing production efficiency. Through CNC technology, the design and production processes of ceramics products have also become more flexible and precise.

Furthermore, grinding technology plays a significant role in ceramics manufacturing. Grinding is an essential step in ceramics processing, improving the smoothness and accuracy of ceramic surfaces. With the continuous development of grinding technology, the quality and appearance of ceramics products have significantly improved.

In the future, the ceramics industry will continue to face challenges in design and machinery manufacturing. With advancing technology, design and manufacturing companies need to continually innovate and improve their techniques to meet market demands and changes. Simultaneously, as market demands for ceramic product quality continue to rise, the ceramics manufacturing industry should focus on quality control and testing technologies.

Aside from the ceramics industry, CNC technology and grinding technology have found wide applications in other machinery manufacturing domains. For instance, CNC technology can be applied in the production of components for industries such as automotive and aerospace, enhancing product precision and reliability. Grinding technology, on the other hand, can be employed in the manufacturing of high-precision tools and components. These applications will further drive the development of CNC technology and grinding technology.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)