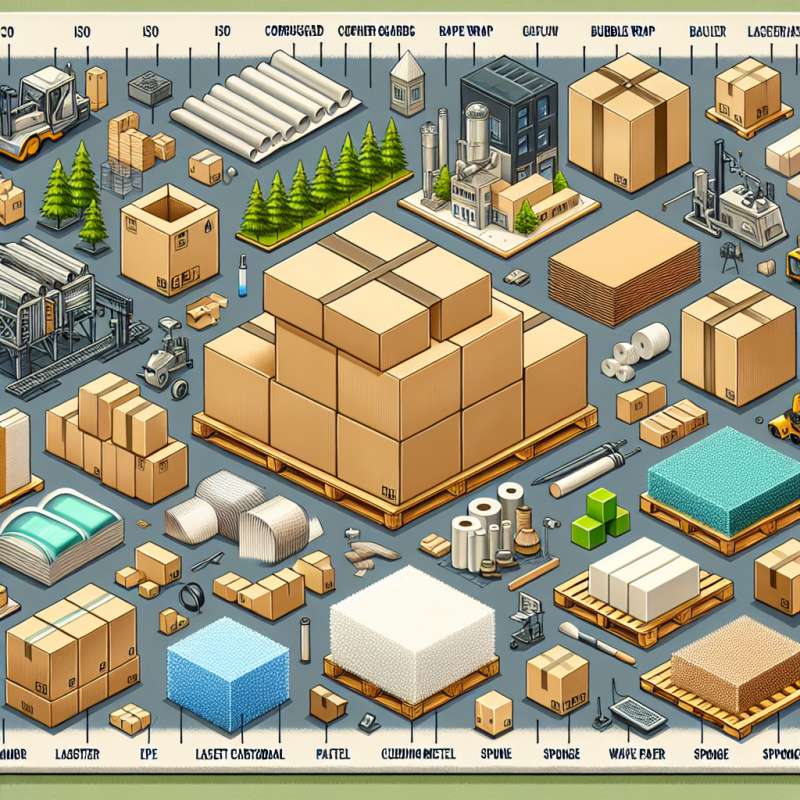

客製化包裝盒及印刷品裝訂加工是現代商業活動中不可或缺的一部分。隨著市場的需求日益增長,這些領域的發展也呈現出令人振奮的趨勢。

在市場演化的新潮流下,客製化已成為各大企業的必要選擇。客戶們希望能夠展現個性化的產品,並將其形象與品牌相結合。客製化包裝盒的需求不斷增加,從而推動了相關產業的發展。製造商們正不斷努力提供更多增值服務,如與客戶合作設計、印刷個性化的包裝盒,以及製造符合客戶需求的特殊形狀和構造的包裝盒。這樣的趨勢會繼續優先考慮客戶的個性化需求,為客戶創造出獨一無二的包裝方式。

印刷技術在客製化包裝盒的製作中起著不可或缺的作用。隨著數位印刷技術的進步,不僅可以實現個性化的印刷需求,還可以更高效地進行生產。數位印刷技術的優勢在於其靈活性和相對較低的成本,這使得製造商能夠更快速地回應客戶的需求。此外,環保意識的提高使得可持續印刷成為趨勢。將環保材料與數位印刷技術相結合,能夠提供可持續發展的解決方案,並符合客戶對環保產品的要求。

除了客製化包裝盒,印刷品裝訂及加工也是一個快速發展的行業。在過去,印刷品裝訂主要集中在傳統的裝訂方式上,如裝訂機器和手工裝訂。然而,隨著技術的進步,數位印刷和自動裝訂的結合催生了更高效和更精確的裝訂方法。自動裝訂機器能夠實現更多機械化的操作,從而提高生產效率和產品質量。此外,自動化裝訂還可以實現個性化需求,如客戶可以選擇不同的裝訂方式(如釘裝、膠裝、騎馬釘等)和加工選項(如烫金、壓紋等)。這樣的發展趨勢將繼續推動印刷品裝訂行業的創新和增長。

總結來看,客製化包裝盒及印刷品裝訂加工的未來趨勢是以客戶需求為導向的發展,並融入數位印刷和自動化裝訂技術。而在環保意識的提高下,可持續發展也將成為重要的發展方向。這些趨勢將不斷推動相關行業的創新和進步,並為客戶提供更好的產品和服務。

關鍵字:customization, packaging boxes, printing, paper boxes, printed materials binding and processing

標題:The Future Trends of Customization in Packaging Boxes and Printed Materials Binding and Processing

Customization in packaging boxes and printed materials binding and processing is an essential part of modern business activities. With the increasing demand in the market, these sectors are showing exciting trends.

In the wave of market evolution, customization has become a necessary choice for major corporations. Customers want to showcase personalized products that can be aligned with their brand image. The demand for customized packaging boxes is constantly growing, which drives the development in the related industries. Manufacturers are striving to provide more value-added services, such as collaborating with customers to design and print personalized packaging boxes, as well as manufacturing boxes with unique shapes and structures tailored to meet customer requirements. This trend will continue to prioritize the personalized needs of customers, creating unique packaging solutions for them.

Printing technology plays an indispensable role in the production of customized packaging boxes. With the advancement of digital printing technology, not only can personalized printing requirements be fulfilled, but production can also be more efficient. The advantages of digital printing lie in its flexibility and relatively lower cost, enabling manufacturers to respond to customer needs more quickly. Additionally, the increasing environmental awareness has made sustainable printing a trend. Combining eco-friendly materials with digital printing technology offers sustainable solutions, meeting customers' demands for environmentally-friendly products.

Apart from customization in packaging boxes, the industry of printed materials binding and processing is also experiencing rapid growth. In the past, printed materials binding mainly focused on traditional binding methods, such as binding machines and manual binding. However, with technological advancements, the combination of digital printing and automated binding has given rise to more efficient and precise binding methods. Automated binding machines can achieve more mechanized operations, thereby improving production efficiency and product quality. Furthermore, automated binding can also cater to personalized demands, such as offering different binding options (e.g., stapling, gluing, saddle stitching) and processing choices (e.g., foil stamping, embossing). This trend will continue to drive innovation and growth in the printed materials binding and processing industry.

In conclusion, the future trends of customization in packaging boxes and printed materials binding and processing lie in customer-centric development, incorporating digital printing and automated binding technology. Moreover, sustainable development will become an important direction under the increasing environmental awareness. These trends will continuously propel innovation and advancement in the related industries, providing customers with better products and services.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)