半導體是現代化社會中不可或缺的元件,被應用於各種產品,從智能手機到自動駕駛汽車。而在半導體的製造過程中,專用機在SMT(表面黏著技術)製造中扮演著重要角色。在本文中,將介紹半導體專用機的設計和開發趨勢,並探討未來的發展前景。

半導體專用機是專為製造半導體產品而設計的機器。它們通常具有高度自動化和精確度,以提高生產效率和降低生產成本。專用機的設計和開發過程中,設計工程師需要考慮到多個因素,包括生產需求、材料特性和最新的技術趨勢。

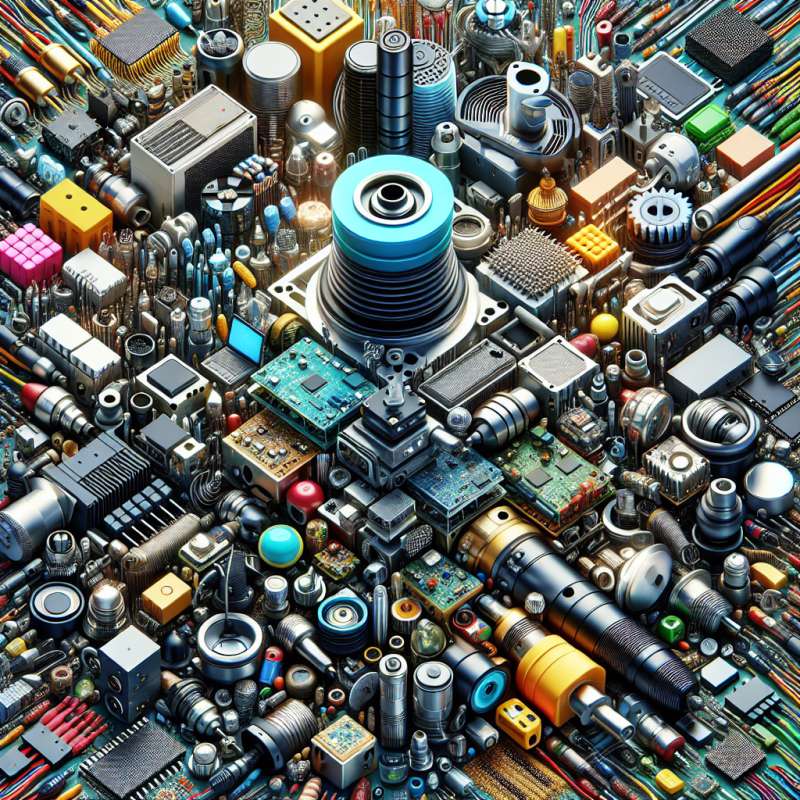

在SMT製造中,專用機的設計和開發起著關鍵作用。SMT是一種將零件焊接到印刷電路板(PCB)上的技術,它使用表面貼裝元件(Surface Mount Devices, SMD),如IC和電容器等。而專用機在這個過程中負責對SMD元件進行準確的放置和焊接。因此,專用機的精度和效率對SMT製造的品質和產能有著重要的影響。

未來,半導體專用機的設計和開發趨勢將朝著以下方向發展:

1. 提高自動化程度:隨著人工智能和機器學習技術的發展,專用機將更加智能化和自動化。這將幫助企業提高生產效率並減少人力成本。同時,自動化還可以提高品質和可靠性,減少人為錯誤的發生。

2. 增強連接性:隨著物聯網(Internet of Things, IoT)的發展,專用機將更加具備連接性,可以與其他設備和系統進行實時數據交換和協同工作。這將提高生產過程的監控和控制,實現智能化的生產環境。

3. 強化耐用性和可靠性:半導體專用機的設計和開發將著重於提高設備的耐用性和可靠性。這樣可以減少設備故障和維修時間,提高生產效率和擴大產值。

總結而言,半導體專用機在SMT製造中扮演著重要角色,其設計和開發趨勢將越來越智能化、自動化和可靠化。未來的發展將朝著提高生產效率和提高品質的方向發展,以滿足不斷增長的半導體市場需求。

關鍵字: Semiconductors, Specialized machines, SMT, Design, Development and Manufacturing

Title: Design and Development Trends of Semiconductor Specialized Machines in SMT Manufacturing

Article:

Semiconductors are vital components in modern society and are utilized in various products, ranging from smartphones to self-driving cars. In the manufacturing process of semiconductors, specialized machines play a significant role in SMT (Surface Mount Technology) manufacturing. In this article, we will explore the design and development trends of semiconductor specialized machines and discuss the future prospects.

Semiconductor specialized machines are designed specifically for the production of semiconductor products. They often feature high automation and precision to enhance production efficiency and reduce manufacturing costs. During the design and development process of specialized machines, engineers must consider multiple factors, including production requirements, material characteristics, and the latest technological trends.

In SMT manufacturing, the design and development of specialized machines are crucial. SMT is a technology that involves the placement and soldering of components onto printed circuit boards (PCBs) using Surface Mount Devices (SMDs) such as ICs and capacitors. Specialized machines are responsible for accurately placing and soldering the SMD components in this process. Therefore, the accuracy and efficiency of specialized machines have a significant impact on the quality and capacity of SMT manufacturing.

In the future, the design and development trends of semiconductor specialized machines will evolve in the following directions:

1. Enhanced automation: With the advancements in artificial intelligence and machine learning technologies, specialized machines will become more intelligent and automated. This will help companies improve production efficiency and reduce labor costs. Moreover, automation can improve quality and reliability while minimizing human errors.

2. Improved connectivity: With the development of the Internet of Things (IoT), specialized machines will possess greater connectivity, allowing real-time data exchange and collaborative work with other devices and systems. This will enhance monitoring and control in the production process, enabling a smarter manufacturing environment.

3. Strengthened durability and reliability: The design and development of semiconductor specialized machines will focus on improving equipment durability and reliability. This will minimize equipment failures and maintenance time, enhancing production efficiency and output.

In conclusion, semiconductor specialized machines play a crucial role in SMT manufacturing, and their design and development trends are moving towards increased intelligence, automation, and reliability. Future developments will focus on improving production efficiency and quality to meet the growing demand in the semiconductor market.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)