近年來,隨著科技的進步和產業的發展,製造業與工程領域的需求也日益增加。在這樣的趨勢下,錫爐製作、焊接代工、鐵架焊接等相關行業更加受到重視。

客製化製作和機架焊接成為產業重要的一環,許多企業專注於提供客製化的解決方案,以滿足客戶個別需求。同時,機架焊接技術也不斷升級,提高了產品的質量和耐用性。

未來,隨著綠色環保意識的抬頭,無鉛溫控錫爐將成為發展的重要趨勢之一。此外,結構殼體加工焊接、CO2氬焊電焊等新技術的應用將進一步提升產業的水準。

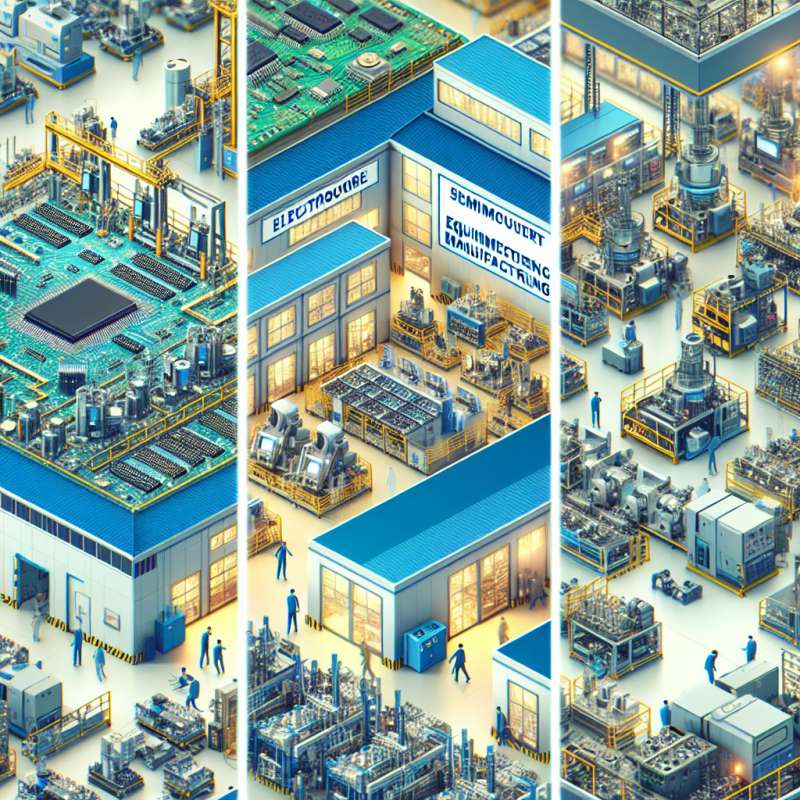

台車鐵櫃焊接代工、電子及半導體生產用機械設備製造也將在未來持續受到關注和需求。這些關鍵技術和產品將助力行業持續茁壯發展。

Keywords: Tin furnace manufacturing, Welding outsourcing, Iron frame welding, Customized production, Frame welding

Title: Future Development Trends in Tin Furnace Manufacturing and Iron Frame Welding Industry

Article: In recent years, with the advancement of technology and the development of industries, the demand for manufacturing and engineering sectors has been increasing. In this trend, industries such as tin furnace manufacturing, welding outsourcing, and iron frame welding are gaining more attention.

Customized production and frame welding have become important aspects of the industry, with many companies focusing on providing customized solutions to meet individual customer needs. At the same time, frame welding technology is constantly being upgraded, improving the quality and durability of products.

In the future, with the rise of green environmental awareness, lead-free temperature-controlled tin furnaces will become an important trend in development. In addition, the application of new technologies such as structural shell processing welding, CO2 argon welding, and electric welding will further enhance the industry's standards.

Welding outsourcing for trolley iron cabinets, as well as the manufacturing of machinery equipment for electronics and semiconductor production, will continue to receive attention and demand in the future. These key technologies and products will help the industry continue to thrive and develop.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)