近年來,全球機械產業發展迅速,不僅與國家經濟發展密不可分,也與人們日常生活息息相關,特別是在半導體、電鍍、污染防治設備製造以及機械設備維修等關鍵領域上,其發展對於促進各行業的創新和發展具有重要意義。本文將探討這些領域的未來發展趨勢和關鍵技術。

半導體是當今科技產業的核心,以其微型化、高效能的特點,廣泛應用於電子產品、通信設備、能源產業等眾多領域。未來,隨著人工智能、物聯網、5G等新興技術的快速發展,半導體產業將迎來更大的發展機遇。新材料、新工藝、先進製造技術將成為半導體產業的關鍵領域,以滿足市場對於高性能、低功耗、小型化產品的需求。

電鍍作為一項重要的表面處理技術,廣泛應用於金屬加工、電子元件、汽車工業等領域。隨著綠色環保理念的提倡和產業要求的提高,未來電鍍技術將會進一步發展,發展趨勢主要體現在減少污染物排放、節能減排、提高鍍層質量等方面。新型電鍍液的開發,以及電鍍設備的自動化、智能化將成為關鍵技術。

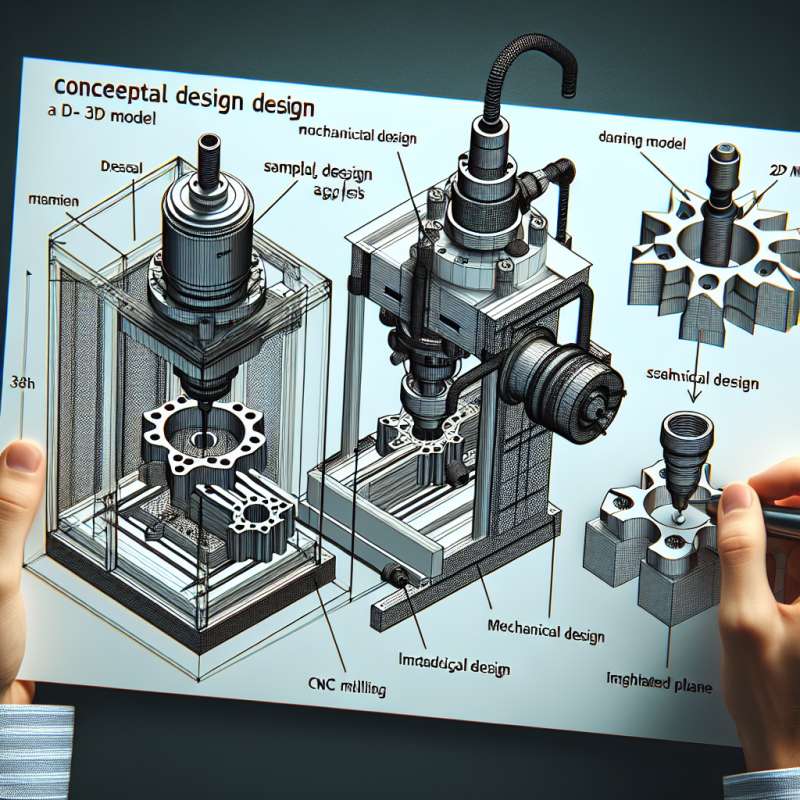

機械產業作為現代工業的基礎,涉及到許多領域,如金屬加工、能源等。未來,機械產業將朝著高效能、智能化的方向發展。機械設備的節能技術、自動化技術、智能制造等將成為發展的關鍵。隨著先進製造技術的應用,機械設備的生產效率將得到提高,同時也將減少資源浪費和環境污染,實現可持續發展。

污染防治設備製造是在環境保護領域中扮演著重要角色的產業。隨著全球環境問題的日益嚴重,對於污染防治的需求也越來越大。未來,隨著綠色技術的成熟和經濟發展的要求,污染防治設備製造將會迎來更多的機遇和挑戰。新型的治理技術、清潔能源裝置、智能監測系統等將成為關鍵技術。

機械設備維修和安裝是機械產業的重要環節,隨著各種機械設備的不斷更新和更換,對於維修和安裝的需求也逐漸增加。未來,隨著機械設備的智能化和自動化,機械設備維修的技術也需要與時俱進。借助遠程監控、故障預測等技術手段,提高維修效率和質量將成為關鍵。

未分類其他機械器具批發是為各個行業提供相關機械器具的供應商。未來,這個領域的發展主要取決於產業變革和市場需求。隨著科技的發展和產業結構的優化升級,機械器具的需求將變得更加個性化和專業化。供應商需要更加關注市場需求,定期更新產品線,以滿足客戶不斷變化的需求。

總結而言,半導體、電鍍、機械、污染防治設備製造以及機械器具批發等領域將成為未來機械產業的關鍵領域。技術創新、綠色發展、智能制造將成為未來發展的主要趨勢。透過加強科研創新、提高產品質量和技術水平,機械產業將有望實現進一步的發展,為各行業的發展和經濟的繁榮做出更大的貢獻。

關鍵字: Semiconductor, Electroplating, Machinery, Pollution Control Equipment Manufacturing, Machinery Maintenance, Machinery Apparatus Wholesale

Title: Future Trends and Key Areas in the Machinery Industry

Article:

In recent years, the global machinery industry has experienced rapid growth, closely tied to the economic development of nations and interconnected with daily life. It is particularly significant in key areas such as semiconductor, electroplating, pollution control equipment manufacturing, machinery maintenance, and machinery apparatus wholesale. This article explores the future trends and key technologies in these fields.

Semiconductor technology has become the core of today's technological industry. With its miniaturization and high-performance features, it is widely applied in electronics, telecommunications, and energy sectors. In the future, as emerging technologies like artificial intelligence, the Internet of Things, and 5G continue to advance, the semiconductor industry will encounter greater opportunities. New materials, advanced processes, and advanced manufacturing technologies will become crucial areas to fulfill the market demand for high-performance, low-power, and miniaturized products.

Electroplating, as an important surface treatment technology, finds wide applications in metal processing, electronic components, and the automotive industry. The future development of electroplating technology will mainly focus on reducing pollutant emissions, energy conservation, emission reduction, and improving coating quality, in line with the promotion of green and eco-friendly concepts and industry requirements. The development of new electroplating solutions and automation and intelligent electroplating equipment will be key technologies.

The machinery industry serves as the foundation of modern industrialization and covers various fields such as metal processing and energy. In the future, the machinery industry will evolve towards high-performance and intelligentization. Energy-saving technologies, automation, and intelligent manufacturing will be critical for development. By applying advanced manufacturing technologies, production efficiency of machinery equipment will be increased while minimizing resource waste and environmental pollution, thereby achieving sustainable development.

Pollution control equipment manufacturing plays a significant role in environmental protection. With the increasing severity of global environmental issues, the demand for pollution control continues to rise. In the future, driven by mature green technologies and economic development needs, pollution control equipment manufacturing will encounter more opportunities and challenges. Key technologies will include innovative purification techniques, clean energy devices, and intelligent monitoring systems.

Machinery maintenance and installation are vital aspects of the machinery industry. As various machinery equipment is constantly updated and replaced, the demand for maintenance and installation steadily grows. In the future, with the advancement of intelligent and automated machinery equipment, maintenance technology must keep pace. Leveraging remote monitoring, fault prediction, and other technological means will improve maintenance efficiency and quality, making it critical for development.

Wholesale of machinery apparatus across various sectors provides essential supplies for different industries. The future development of this field predominantly relies on industrial transformation and market demand. With technological advancements and structural optimization, the demand for machinery apparatus will become more personalized and specialized. Suppliers need to pay closer attention to market needs, regularly update product lines, and meet the ever-changing demands of customers.

In conclusion, the fields of semiconductor, electroplating, machinery, pollution control equipment manufacturing, and machinery apparatus wholesale will be vital areas in the future machinery industry. Technological innovation, green development, and intelligent manufacturing will be the main trends. By strengthening scientific research, improving product quality, and elevating technological standards, the machinery industry is expected to achieve further development, contributing to the progress of various sectors and economic prosperity.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)