關於印刷品製作流程的一貫作業,包裝及印刷是其中非常重要的環節。這篇文章將探討這兩個關鍵領域的重要性以及未來的發展趨勢。

包裝在印刷品製作流程中佔據了重要的地位。它不僅僅是一個保護產品的外殼,更是通過視覺傳達與平面設計來吸引消費者的注意。適當的包裝能夠提升產品的價值和質感,將品牌形象傳達給消費者。未來,我們可以預見包裝將更加注重環保和可持續發展。例如,使用可循環再利用的材料或發展可降解的包裝材料,將成為包裝行業的未來發展方向。

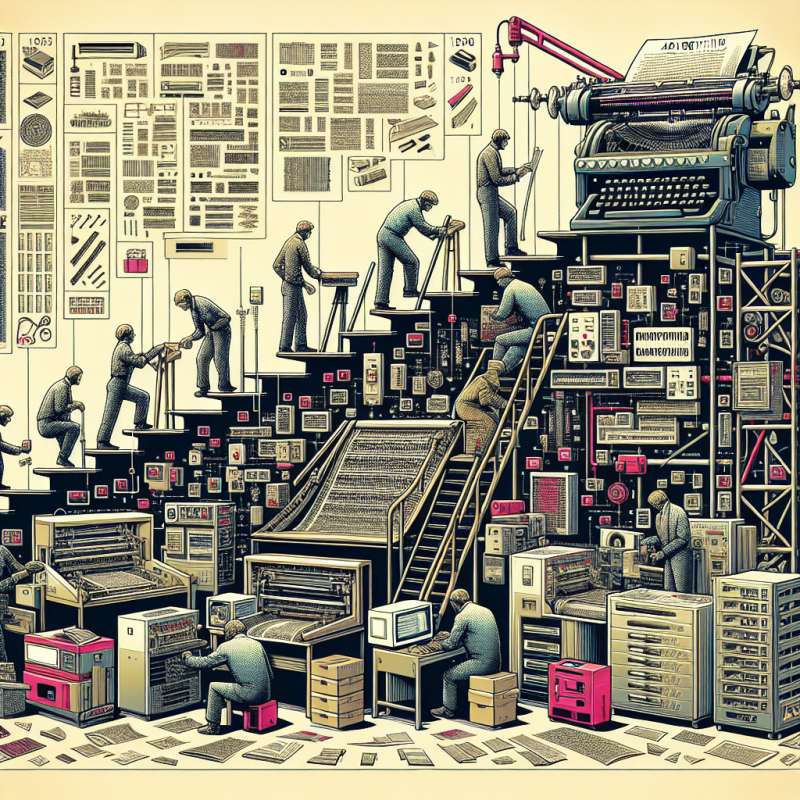

印刷是印刷品製作流程中不可或缺的一環。它涉及到印刷技術的應用、印刷品的製作和印刷品裝訂及加工等方面。隨著數位技術的發展,傳統的印刷方式正在逐漸被數位印刷所取代。數位印刷具有快速、靈活和個性化的優勢,可以根據客戶的需求來定制印刷品。此外,數位印刷還可以降低生產成本,提高產能。因此,未來印刷品製作流程中,數位印刷技術將扮演更重要的角色。

醫療耗材批發是印刷品製作流程中另一個重要的領域。隨著人民生活水平的提高和健康意識的增強,醫療耗材的需求也在持續增加。醫療耗材批發能夠提供各種不同的醫療耗材產品給醫療機構,確保其正常運營。未來,隨著醫療技術的不斷進步,醫療耗材的種類和規格也會不斷擴大。此外,隨著人們對醫療耗材質量和安全性的要求提高,醫療耗材批發商需要不斷提升其品牌形象和產品質量,以滿足市場的需求。

綜上所述,印刷品製作流程中的一貫作業、包裝、印刷、醫療耗材批發等領域,都在不斷發展和創新。對於未來的發展趨勢來說,我們應關注環保與可持續發展、數位印刷技術的應用以及醫療耗材的多樣化需求。只有不斷適應和創新,才能在競爭激烈的市場中取得競爭優勢。

關鍵字: control, RO, digital, raw materials, printing

標題: The Role of Control and RO in the Future Development of Digital Printing with Raw Materials

Control and RO are crucial factors in the future development of digital printing with raw materials. This article explores the importance of these key areas and the future trends in the industry.

Control plays a critical role in the digital printing process. It involves ensuring the consistency and quality of the printed materials. With the advancement of technology, control systems have become more sophisticated, allowing for accurate color management, image adjustments, and print calibration. Additionally, control systems help optimize production processes, reduce waste, and improve efficiency. In the future, we can expect to see more advanced control systems that enhance productivity and enable seamless printing operations.

RO (Return on Investment) is another essential aspect of digital printing. As the printing industry becomes more competitive, companies need to invest wisely in digital printing technology to achieve a higher ROI. Digital printing offers several advantages, including faster printing speed, personalized printing capabilities, and cost-effective production. To maximize RO, businesses should consider factors such as maintenance cost, equipment lifespan, and the potential for future upgrades and expansion. Additionally, businesses should stay updated on the latest industry trends, such as new printing techniques and materials, to stay ahead of the competition.

Digital printing relies heavily on raw materials. The selection of raw materials can greatly influence the quality and durability of the end product. In recent years, there has been a shift towards eco-friendly and sustainable raw materials in the printing industry. This trend is expected to continue in the future, with more emphasis on using recycled or biodegradable materials. Advances in raw material technology will also play a significant role in improving print quality, reducing environmental impact, and enhancing overall printing performance.

In conclusion, control, RO, digital technology, and raw materials are all interconnected in the future development of digital printing. The industry's focus on control systems and RO optimization will drive efficiency and cost-effectiveness. Additionally, the adoption of eco-friendly raw materials will contribute to sustainable printing practices. Embracing the latest trends and innovations in these areas will be essential for businesses to stay competitive and meet the ever-evolving demands of the printing market.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)