近年來,NCT鈑金和自動化設備在金屬加工製造業中扮演著非常重要的角色。NCT鈑金技術是一種高效率的金屬板料加工技術,可以實現金屬板料的快速切割和成型,並且精度高、成本低。而自動化設備的應用則可以提高生產效率,降低人力成本,並且確保產品質量一致。

在金屬加工處理方面,氬焊是一種常見的焊接技術,可以實現金屬件的高強度連接,同時也可以提高產品的耐用程度。以及在電路工程領域,金屬加工製造業也需要考慮金屬與電路元件的結合,在製造過程中要注意電氣性能的穩定性和可靠性。

融合這些新興技術和金屬加工製造業,可以大幅提升公司的產品競爭力,加速生產週期,並提高整體作業效益。為了在激烈的市場競爭中立於不敗之地,金屬加工製造業需要不斷更新技術,並尋找創新的解決方案。

Translation:

Keywords: NCT sheet metal, automation equipment, argon welding, metal processing, circuit engineering

Title: Application of Emerging Technologies in Metal Processing Manufacturing Industry

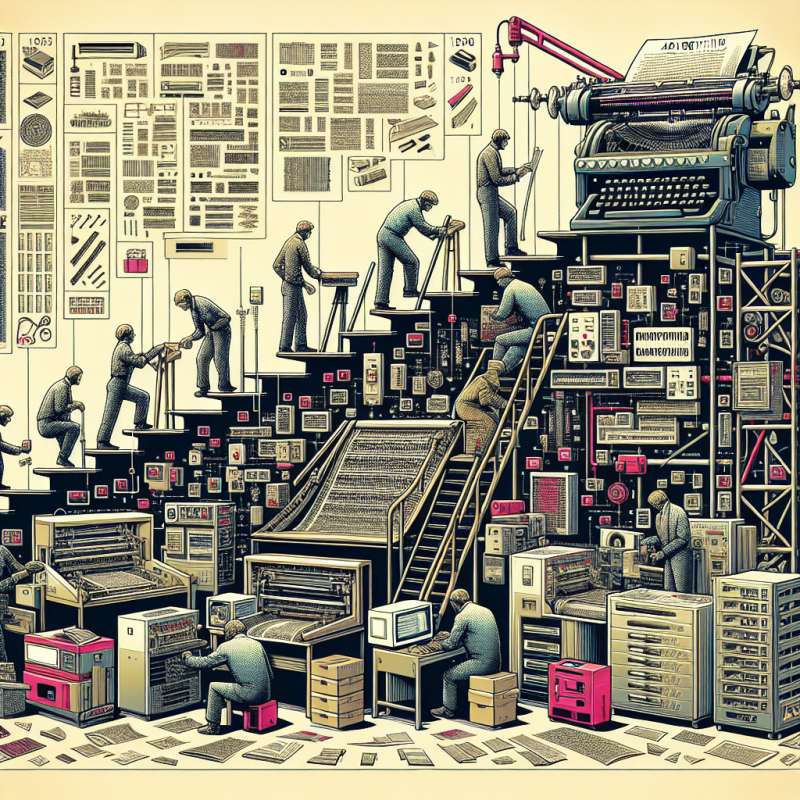

Article: In recent years, NCT sheet metal and automation equipment have played a crucial role in the metal processing manufacturing industry. NCT sheet metal technology is an efficient metal sheet processing technique that enables rapid cutting and shaping of metal sheets with high precision and low cost. The application of automation equipment can improve production efficiency, reduce labor costs, and ensure consistent product quality.

In terms of metal processing, argon welding is a common welding technique that enables high-strength connections of metal components and enhances product durability. In the field of circuit engineering, the metal processing manufacturing industry also needs to consider the integration of metal with circuit components, paying attention to the stability and reliability of electrical performance during the manufacturing process.

By integrating these emerging technologies with the metal processing manufacturing industry, companies can significantly enhance their product competitiveness, accelerate production cycles, and improve overall operational efficiency. To stay ahead in the competitive market, the metal processing manufacturing industry needs to continuously update their technologies and seek innovative solutions.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)