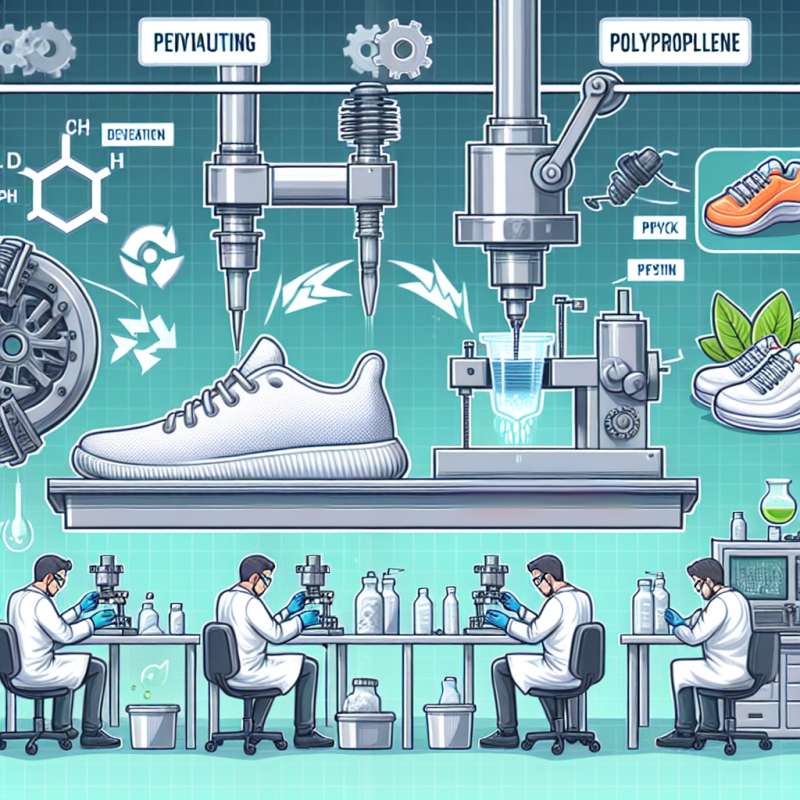

近年來,塑膠鞋材製造業因其生產製造過程中使用的原料聚乙烯 (PE) 和聚丙烯 (PP) 而受到關注。這些高密度的塑料材料通常通過射出成型來製造塑膠鞋材。然而,隨著環境議題日益受到重視,塑膠製品的生產和使用也面臨著挑戰。

未來發展趨勢顯示,塑膠鞋材製造業將朝著更環保的方向發展。企業將不僅需要關注生產過程中的環境影響,也要思考如何更有效地利用資源。針對塑膠原料的再生利用和循環利用將成為業界的一個重要趨勢,以減少對自然資源的消耗和減少塑膠廢棄物對環境造成的負面影響。

因此,塑膠鞋材製造業在未來的發展中將更加注重研發環保技術和改進生產過程,以降低對環境的影響。透過採用更有效的生產方法和利用可再生資源,塑膠鞋材製造業將能夠實現可持續發展,同時為環境保護盡一份力。

Keywords: Production Manufacturing, Polyethylene, Injection Molding, Environment, Future Trends

Title: Future Trends in Plastic Shoe Material Manufacturing

Article: In recent years, the plastic shoe material manufacturing industry has received attention due to the use of materials such as polyethylene (PE) and polypropylene (PP) in the production process. These high-density plastic materials are typically manufactured into plastic shoe materials through injection molding. However, as environmental issues are increasingly emphasized, the production and use of plastic products also face challenges.

Future trends indicate that the plastic shoe material manufacturing industry will move towards a more eco-friendly direction. Companies will not only need to pay attention to the environmental impacts during production processes but also consider how to use resources more effectively. The recycling and reuse of plastic materials will become an important trend in the industry to reduce the consumption of natural resources and minimize the negative impact of plastic waste on the environment.

Therefore, the future development of the plastic shoe material manufacturing industry will focus more on researching and developing environmentally friendly technologies and improving production processes to reduce environmental impact. By adopting more efficient production methods and utilizing renewable resources, the plastic shoe material manufacturing industry will be able to achieve sustainable development while contributing to environmental protection.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)