近年來,製造業一直是台灣經濟的支柱之一,其中包括了木工機械設備製造、其他金屬刀具及手工具製造、污染防治設備製造和塑膠外殼及配件製造。以下將探討這些產業的未來發展趨勢。

對於木工機械設備製造業而言,國內需求一直穩定增長。隨著綠色環保意識的提高,未來將更加強調節能減碳,推動調整木工機械設備的產品結構和技術水平。此外,自動化生產和智能化控制也將成為未來發展的關鍵。因此,研發和創新將是木工機械設備製造業的重要目標。

其他金屬刀具及手工具製造業也面臨類似的挑戰和機遇。隨著科技進步,傳統的金屬刀具和手工具將不斷被創新和高效的技術所取代。例如,3D列印技術的應用將帶來全新的製造方式和產品設計。此外,為了提高生產效率,智能製造系統也將得到廣泛應用。這些趨勢要求業者不斷進行研發和技術提升,以應對市場的變化和需求。

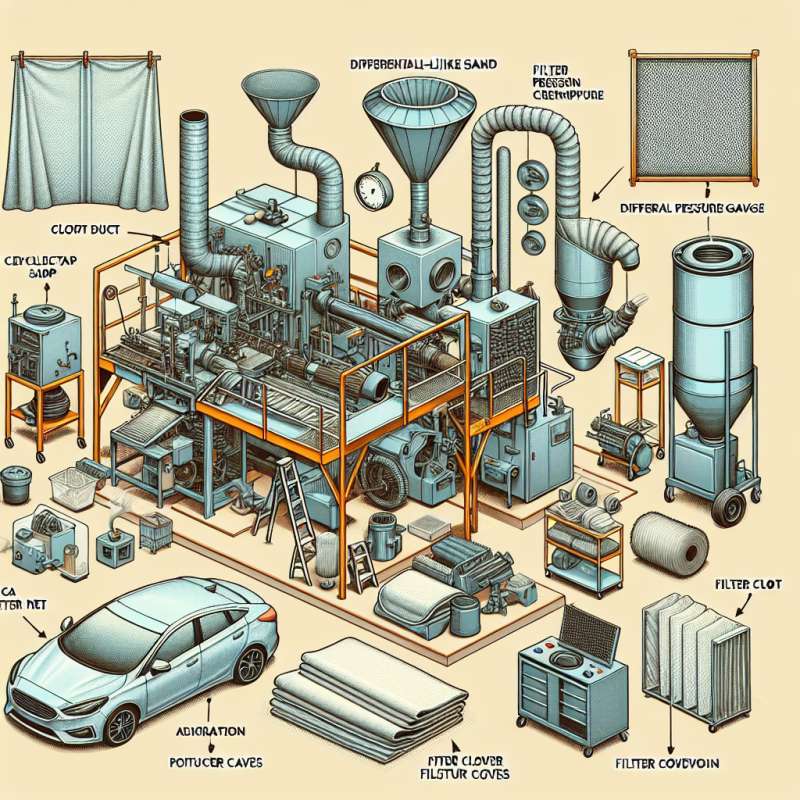

而在污染防治設備製造業方面,綠色和環保已成為行業的主題。由於環境問題的日益嚴峻,需求和政府的監管加強,這個行業的未來發展前景看好。為了滿足更嚴格的環保要求,污染防治設備需不斷創新,提高技術水平和效能。此外,可再生能源設備將成為未來的發展重點,如太陽能發電設備、風力發電設備等。

塑膠外殼及配件製造業面臨著多樣的市場需求。未來,這個行業將更加關注綠色環保和輕量化產品的發展。隨著塑膠製造技術的提升,生產過程中的能源和資源消耗將有所減少。同時,由於物聯網和智能設備的發展,塑膠外殼製造商將面臨機遇和挑戰。例如,智能手機的普及對塑膠外殼的需求增加,但競爭也變得更加激烈。

總結來說,未來發展趨勢將促使這些製造業創新和發展。節能減碳、自動化和智能化、綠色環保、可再生能源以及輕量化產品都將成為未來的關鍵。面對這些挑戰和機遇,業者應积極進行研發和技術提升,以提高競爭力並滿足市場需求。

Title: Key Trends for Future Development - Driving Innovation in the Manufacturing Industry

Article:

In recent years, the manufacturing industry has been one of the pillars of the Taiwan economy, including the manufacturing of woodworking machinery, other metal cutting tools and hand tools, pollution control equipment, and plastic enclosures and accessories. This article explores the future development trends of these industries.

For the woodworking machinery manufacturing industry, domestic demand has been steadily growing. With the increasing awareness of green and environmental protection, future development will emphasize energy conservation and carbon reduction, promoting the adjustment of product structures and technological levels of woodworking machinery. In addition, automated production and intelligent control will also be key to future development. Therefore, research and development (R&D) and innovation will be important goals for the woodworking machinery manufacturing industry.

The manufacturing of other metal cutting tools and hand tools also confronts similar challenges and opportunities. With technological advancements, traditional metal cutting tools and hand tools will be continuously replaced by innovative and efficient technologies. For example, the application of 3D printing technology will bring about new manufacturing methods and product designs. Additionally, to improve production efficiency, intelligent manufacturing systems will be widely utilized. These trends require manufacturers to engage in continuous R&D and technological advancements to adapt to market changes and demands.

In terms of pollution control equipment manufacturing, green and environmental protection have become the industry's focus. With the increasingly severe environmental issues and strengthened demand and government regulations, this industry has promising future prospects. To meet stricter environmental requirements, pollution control equipment needs to continuously innovate, enhance technological levels, and improve efficiency. Additionally, renewable energy equipment will be a key focus for future development, such as solar power equipment and wind power equipment.

The manufacturing of plastic enclosures and accessories faces diverse market demands. In the future, this industry will pay more attention to the development of green and lightweight products. With the improvement of plastic manufacturing technology, energy and resource consumption in the production process will be reduced. Simultaneously, due to the development of the Internet of Things and smart devices, plastic enclosure manufacturers will encounter opportunities and challenges. For example, the proliferation of smartphones increases the demand for plastic enclosures, but the competition becomes more intense.

In conclusion, future development trends will drive innovation and development in these manufacturing industries. Energy conservation and carbon reduction, automation and intelligence, green and environmental protection, renewable energy, and lightweight products will all be key factors. Faced with these challenges and opportunities, manufacturers should actively engage in R&D and technological advancements to enhance competitiveness and meet market demands.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)