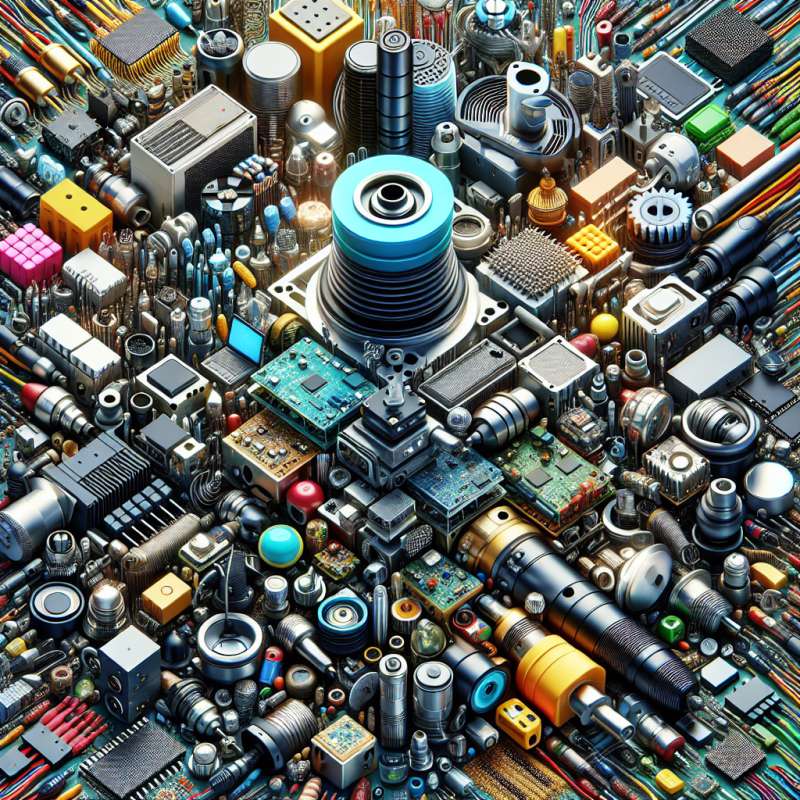

近年來,隨著科技的發展與創新,自動化製造成為各行各業追求的目標之一。控制桌、配電箱和雷射沖孔機作為未來製造業的重要機械設備之一,隨著技術的不斷進步,將迎來更加廣闊的發展前景。

控制桌是一種用於控制和監測生產流程的關鍵設備。它通常由電腦終端、觸摸屏和各種儀器儀表組成,可以實現自動化控制、數據記錄和監測功能。在未來,隨著製造業的智能化發展,控制桌將更加精確、高效地執行任務,提高生產效率,降低人力成本。

配電箱在能源管理中扮演著重要的角色。它用於接收、分配和控制電力供應,保護電器設備免受過載和短路的損壞。未來,隨著清潔能源和可再生能源的不斷普及,配電箱將具有更好的節能效果和穩定性。同時,配電箱將與智能電網相連接,實現遠程監控和智能控制,提高能源利用率。

雷射沖孔機是一種高效、精確的鈑金加工設備。它通過高能雷射束對金屬材料進行切割、沖孔和加工,實現複雜形狀和細小尺寸的零件加工。未來,隨著工業4.0的普及和數字化製造的興起,雷射沖孔機將更加智能化和自動化。它將與其他製造設備相連接,實現自動化生產線的無人化運營,提高生產效率和產品質量。

總之,未來控制桌、配電箱和雷射沖孔機將向更高效、智能化方向發展。隨著技術的繼續進步和應用的擴大,這些機械設備領域將為製造業帶來更多的創新和發展機會。

關鍵字: control desk, distribution box, laser punching machine

標題: Future Trends: The Application of Automation in Control Desks, Distribution Boxes, and Laser Punching Machines

In recent years, with the development and innovation of technology, automation has become one of the goals pursued by various industries. Control desks, distribution boxes, and laser punching machines, as important mechanical equipment in the future manufacturing industry, are expected to have a broad development prospect with the continuous advancement of technology.

Control desks are crucial equipment used for controlling and monitoring production processes. They typically consist of computer terminals, touch screens, and various instruments and meters, enabling automated control, data recording, and monitoring functions. In the future, with the intelligent development of the manufacturing industry, control desks will execute tasks with greater precision and efficiency, improving production efficiency and reducing labor costs.

Distribution boxes play an important role in energy management. They are used to receive, distribute, and control power supply while protecting electrical equipment from overload and short circuit damage. In the future, with the widespread adoption of clean and renewable energy, distribution boxes will have better energy-saving effects and stability. Simultaneously, distribution boxes will be connected to smart grids, enabling remote monitoring and smart control to improve energy utilization efficiency.

Laser punching machines are efficient and precise sheet metal processing equipment. They utilize high-energy laser beams to cut, punch, and process metal materials, enabling the fabrication of complex shapes and small-sized parts. In the future, with the popularity of Industry 4.0 and the rise of digital manufacturing, laser punching machines will become more intelligent and automated. They will be interconnected with other manufacturing equipment to realize unmanned operation of automated production lines, improving production efficiency and product quality.

In conclusion, control desks, distribution boxes, and laser punching machines will move towards a more efficient and intelligent direction in the future. With continued technological advancements and wider applications, these mechanical equipment fields will bring more opportunities for innovation and development in the manufacturing industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)