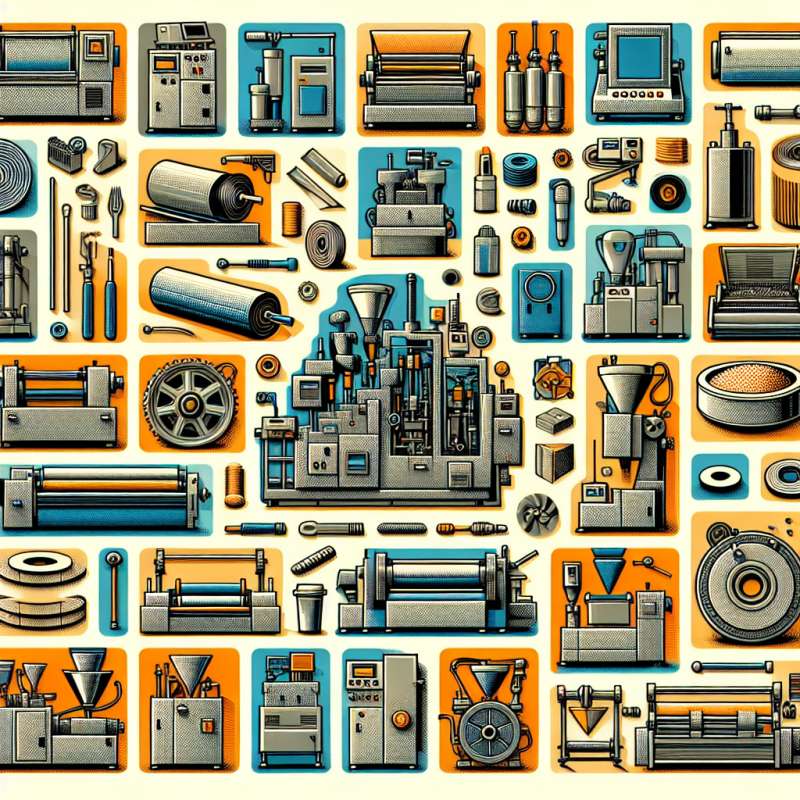

近年來,全球橡膠及塑膠加工行業急速發展,對於押出機、造粒機等機械設備的需求越來越大。押出機和造粒機是橡膠及塑膠製品製造過程中不可或缺的關鍵設備,它們可以將原料加熱後壓條押出,再經過造粒處理,得到所需的成品顆粒。

隨著科技不斷進步,橡膠及塑膠加工機械設備製造領域也將朝著更智能化、自動化的方向發展。未來的押出機和造粒機將更加節能環保,可以實現智能控制和遠程監控,提高生產效率和品質。

密煉機、WSM等高端設備的應用也將逐漸擴大,以滿足市場對高品質橡膠及塑膠製品的需求。橡膠及塑膠加工機械製造企業應加強研發創新,不斷提升設備的技術水平和性能,以應對市場競爭壓力。

關鍵字: extruder, pellete, rubber and plastic processing machinery manufacturing

Title: Future Development Trends of Rubber and Plastic Processing Machinery

Article: In recent years, the global rubber and plastic processing industry has been developing rapidly, leading to a growing demand for machinery such as extruders and pelletizers. Extruders and pelletizers are essential equipment in the manufacturing process of rubber and plastic products, as they can heat and press materials to form strips, which are then processed into the desired finished granules.

With continuous technological advancements, the field of rubber and plastic processing machinery manufacturing will also move towards a more intelligent and automated direction. Future extruders and pelletizers will be more energy-efficient and environmentally friendly, with the ability to achieve intelligent control and remote monitoring, thereby enhancing production efficiency and quality.

The application of high-end equipment such as kneaders and WSM will also gradually expand to meet the market demand for high-quality rubber and plastic products. Rubber and plastic processing machinery manufacturing enterprises should strengthen research and development innovation, continuously improve the technical level and performance of equipment, in order to cope with market competition.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)