近年來,精密鑄造技術在電子零件製造領域中扮演著越來越重要的角色。台中地區的壓鑄廠擁有各種大型壓鑄機,包括800噸、1000噸和1250噸的設備,可用於鋁壓鑄和鋅壓鑄,以及其他精密壓鑄工藝。

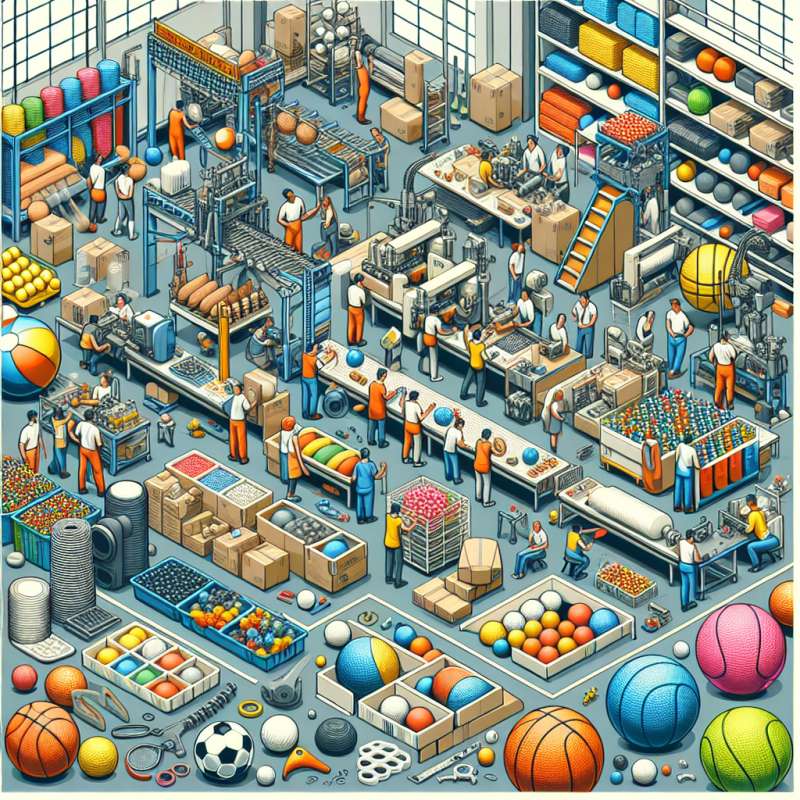

精密鑄造技術能夠製造出高精度、複雜形狀的電子零件,如汽車電力系統製造中所需的部件。同時,這些零件也常用於木工機械、體育用品製造和金屬模具製造等行業中。鋁合金壓鑄和鋁合金鑄造技術的應用,不僅可以提高產品的質量和耐用性,還可以實現較輕的重量和更高的效能。

隨著科技的不斷進步,精密鑄造技術將會繼續在電子零件製造中扮演重要角色。高壓鑄造和精密鑄造技術的應用將進一步擴展,並為未來電子產品的發展帶來更多可能性。

Translation:

Keywords: Electronics Components, Precision Casting, High Pressure Casting

Title: The Application of Precision Casting Technology in Electronic Components Manufacturing

Article: In recent years, precision casting technology has been playing an increasingly important role in the manufacturing of electronic components. In the Taichung area, pressure casting factories possess various large-scale casting machines, including equipment ranging from 800 tons to 1250 tons, which can be used for aluminum and zinc casting, as well as other precision casting processes.

Precision casting technology can produce high-precision, complex-shaped electronic components, such as parts required in the manufacturing of automotive power systems. These components are also commonly used in industries such as woodworking machinery, sports equipment manufacturing, and metal mold production. The application of aluminum alloy casting and aluminum alloy casting technology can not only improve the quality and durability of products but also achieve lighter weight and higher efficiency.

With the continuous advancement of technology, precision casting technology will continue to play an important role in the manufacturing of electronic components. The application of high-pressure casting and precision casting technology will further expand, bringing more possibilities for the development of future electronic products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)