近年來,隨著科技的快速發展和智慧交通的興起,汽車電力系統的需求大幅增加。在這個行業中,全方位的電腦加工技術發揮了重要的作用。無論是在零件製造、設計或組裝等方面,電腦加工都成為不可或缺的一環。

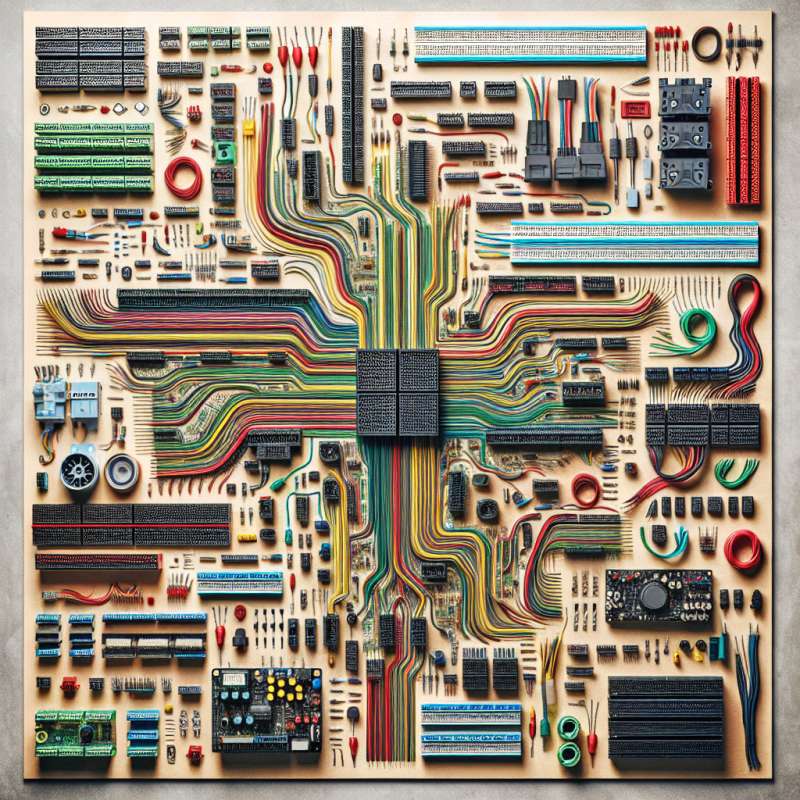

電腦加工技術是指利用電腦控制機械設備來進行材料的加工和製造。這種技術可以提高生產效率和產品質量,並且具有較高的自動化水平。在汽車電力系統製造過程中,電腦加工可以用於製造各種零件,例如電子連接器、汽車控制模組等。

未來,隨著汽車工業的發展,汽車電力系統將持續朝更高效、更智能的方向發展。在這個趨勢下,電腦加工將發揮更加重要的作用。首先,全方位的電腦加工將可以實現更高精度的零件製造,從而提高整個系統的性能和可靠性。其次,電腦加工可以實現更快速的設計和生產週期,大幅縮短產品的上市時間。最後,電腦加工還可以實現更靈活的生產方式,從而適應不斷變化的市場需求。

除了在汽車電力系統製造中的全方位應用,電腦加工還在其他行業中廣泛使用。例如,電子產品的製造、工廠的自動化生產、模具製造等都需要電腦加工技術的支持。隨著人們對科技產品的需求日益增加,電腦加工行業有著十分廣闊的發展前景。

關鍵字:全方位, 電子, 加工, 零件, 電腦

標題: 電子零件加工的全方位發展趨勢

在現代科技發展的浪潮下,電子產品的需求呈現出快速增長的趨勢。在這個行業中,全方位的電子零件加工發揮了重要的作用。無論是在設計、加工或組裝等方面,全方位的電子零件加工都成為不可或缺的一環。

電子零件的加工是指將原材料進行製造和加工,以便用於電子產品的製造。在這個過程中,電腦技術的應用變得至關重要。通過利用電腦控制的加工設備,可以實現高精度、高效率的製造過程。這不僅可以提高產品的質量,還可以大幅提高生產效率。

未來,隨著科技的不斷發展,電子產品將越來越小型化、輕量化和智能化。這將對電子零件的加工提出更高的要求。首先,全方位的電子零件加工將保證高精度的加工品質,以應對微小電子元件的加工需求。其次,加工過程的自動化和智能化將有效地提高生產效率和產品品質。此外,將更多使用先進的材料和製造技術,如3D打印等,以實現更靈活和可定制的生產模式。

除了電子零件加工,全方位的電子應用還在其他行業中得到廣泛應用。例如,家電產品、通訊設備、機械製造等都需要使用電子零件。因此,電子零件加工行業有著十分廣闊的市場前景,未來將繼續迎來更多的發展機遇。

關鍵字: 加工, 模具, 金屬結構製造

標題: 加工模具在金屬結構製造中的重要作用

金屬結構製造是指利用金屬材料進行製造和加工,以創造各種金屬結構產品。在這個過程中,加工模具起著重要的作用。利用加工模具,可以實現對金屬材料進行精確切割、成型和加工的目的。

加工模具是指製作新產品的模具,通常由特定材料製成,具有特定的形狀和尺寸。它通過加工機械的控制,將金屬材料加工成所需形狀的結構。在金屬結構製造中,加工模具可以實現高度精確的加工效果,並且具有較高的生產效率。

未來,隨著建築和製造行業的發展,金屬結構製造將持續成為重要的行業。在這一趨勢下,加工模具的需求也將大幅增加。首先,加工模具的技術將不斷創新和發展,以實現更高效、更精確的加工效果。其次,加工模具的自動化和智能化水平將不斷提高,以應對需求快速變化的市場。最後,加工模具將越來越適應特定金屬結構產品的製造需求,實現更多定制化的生產。

除了在金屬結構製造中的應用,加工模具還在其他行業中得到廣泛應用。例如,塑料製品、電子產品、汽車配件等都需要使用加工模具。因此,加工模具行業有著廣闊的市場前景,並將繼續迎來新的發展機遇。

Title: The Comprehensive Application of Computer Processing in the Manufacturing of Automotive Power Systems

Keywords: Comprehensive, Computer, Processing, Automotive Power System

Article:

In recent years, with the rapid development of technology and the rise of intelligent transportation, the demand for automotive power systems has increased significantly. In this industry, comprehensive computer processing technology plays a crucial role. Whether it is in parts manufacturing, design, or assembly, computer processing has become an indispensable part.

Computer processing technology refers to the use of computer-controlled machinery to process and manufacture materials. This technology can improve production efficiency and product quality, and it has a high level of automation. In the manufacturing process of automotive power systems, computer processing can be used to manufacture various parts, such as electronic connectors and automotive control modules.

In the future, with the development of the automotive industry, automotive power systems will continue to evolve towards greater efficiency and intelligence. In this trend, computer processing will play an even more critical role. Firstly, comprehensive computer processing will enable higher precision in part manufacturing, thereby improving the overall system performance and reliability. Secondly, computer processing can achieve faster design and production cycles, greatly reducing time to market for products. Lastly, computer processing can also enable more flexible production methods to adapt to ever-changing market demands.

In addition to its comprehensive application in the manufacturing of automotive power systems, computer processing is also widely used in other industries. For example, it is essential in the manufacturing of electronic products, factory automation, and mold manufacturing. With the increasing demand for technological products, the computer processing industry has vast development prospects.

Title: Comprehensive Development Trends in Electronic Component Processing

Keywords: Comprehensive, Electronic, Processing, Parts, Computer

Article:

In the wave of modern technological advancements, the demand for electronic products is experiencing rapid growth. In this industry, comprehensive electronic component processing plays a crucial role. Whether it is in design, processing, or assembly, comprehensive electronic component processing has become an essential part.

Electronic component processing refers to the manufacturing and processing of raw materials for use in electronic product production. In this process, the application of computer technology becomes crucial. By using computer-controlled processing equipment, high precision and high-efficiency manufacturing processes can be achieved. This not only enhances the quality of the products but also significantly improves production efficiency.

In the future, with the continuous development of technology, electronic products will become more compact, lightweight, and intelligent. This will bring higher requirements for electronic component processing. Firstly, comprehensive electronic component processing will guarantee high precision in manufacturing, catering to the needs of processing tiny electronic components. Secondly, the automation and intelligence of the processing process will effectively improve production efficiency and product quality. Additionally, advanced materials and manufacturing technologies such as 3D printing will be utilized for more flexible and customizable production modes.

Apart from electronic component processing, comprehensive electronic applications are also widely used in other industries. For example, household appliances, communication devices, and mechanical manufacturing all require the use of electronic components. Therefore, the electronic component processing industry has broad market prospects and will continue to encounter further development opportunities.

Title: The Significance of Mold Processing in Metal Structural Manufacturing

Keywords: Processing, Mold, Metal Structural Manufacturing

Article:

Metal structural manufacturing refers to the manufacturing and processing of metal materials to create various metal structural products. In this process, mold processing plays a crucial role. Through mold processing, precise cutting, forming, and processing of metal materials can be achieved.

Mold processing refers to the production of molds for new products, typically made of specific materials with specific shapes and sizes. It utilizes computer-controlled machinery to process metal materials into desired structural shapes. In metal structural manufacturing, mold processing can achieve highly precise processing effects and has high production efficiency.

In the future, as the construction and manufacturing industries continue to develop, metal structural manufacturing will remain an important industry. In this trend, the demand for mold processing will also increase significantly. Firstly, mold processing technology will continuously innovate and develop to achieve more efficient and precise processing effects. Secondly, the automation and intelligence level of mold processing will continue to improve to meet the market's fast-changing demands. Lastly, mold processing will become more adaptable to the manufacturing needs of specific metal structural products, offering more customization in production.

In addition to its application in metal structural manufacturing, mold processing is widely used in other industries. For example, it is necessary in the production of plastic products, electronic products, and automotive components. Therefore, the mold processing industry has broad market prospects and will continue to encounter new development opportunities.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)