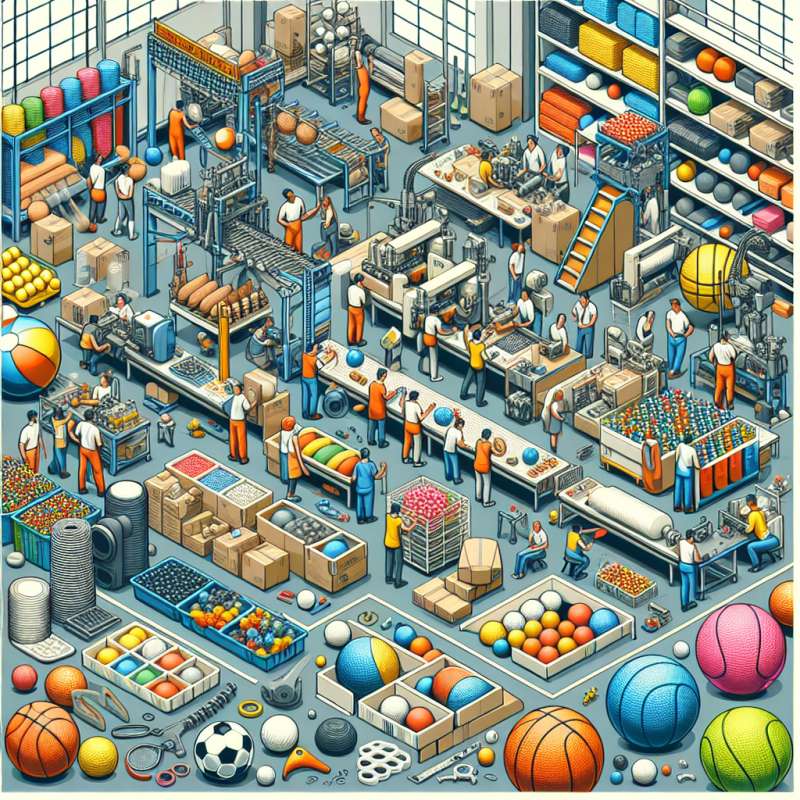

隨著工業緊迫的現代社會需求不斷增加,橡膠製品在各個領域中扮演著重要角色。其中,橡膠製品製造的技術不斷進步,透過矽膠環帶製作和壓花輪製作等先進技術,產品的品質和效能也隨之提升。

未來的發展趨勢將會著重在提高產品的耐用性和多功能性。矽膠環帶製作技術的應用將使橡膠製品更耐磨、耐高溫、耐化學品,同時擁有較好的彈性和導電性能。而壓花輪製作則可以為產品增加獨特的表面紋理,提升外觀吸引力,滿足消費者對美觀的需求。

除了以上技術,未來橡膠製品製造業也可能會著眼於開發彎曲輪製作和轆桶披覆橡膠等創新技術,以應對不斷變化的市場需求。透過這些技術的應用,製造商可以生產出更加耐用且功能更加全面的橡膠製品,滿足不同行業的需求。

總的來說,未來橡膠製品製造業將會不斷追求技術創新,提高產品品質和性能,以滿足市場對高品質產品的需求,促進整個行業的發展。

關鍵字: Rubber products, Silicone belt production, Embossing wheel manufacturing, Industrial pressure

Title: Future Trends in Rubber Products Manufacturing

Article: With the increasing demand in today's fast-paced industrial society, rubber products play a crucial role in various fields. The manufacturing technology of rubber products continues to advance, and with advanced techniques such as silicone belt production and embossing wheel manufacturing, the quality and efficiency of products have also improved.

Future trends will focus on enhancing the durability and versatility of products. The application of silicone belt production technology will make rubber products more wear-resistant, heat-resistant, chemical-resistant, while also possessing better elasticity and conductivity. Embossing wheel manufacturing can add unique surface textures to products, enhancing aesthetic appeal and meeting consumers' demand for beauty.

In addition to the above technologies, the future of rubber products manufacturing may also focus on developing innovative technologies such as curved wheel manufacturing and rubber-coated rollers to address the constantly changing market demands. Through the application of these technologies, manufacturers can produce more durable and comprehensive rubber products to meet the needs of various industries.

In conclusion, the future of rubber products manufacturing will continue to pursue technological innovation, improve product quality and performance to meet the market demand for high-quality products, and promote the development of the entire industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)