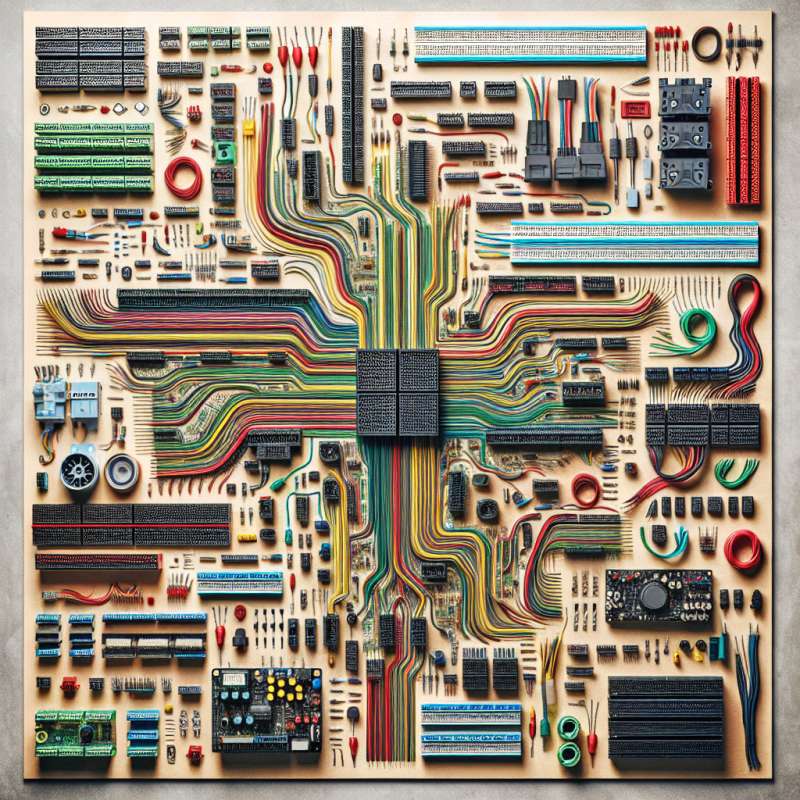

隨著現代電子產品的持續迭代和需求增長,被動電子元件製造成為電子行業中不可或缺的一部分。在被動電子元件中,我們介紹幾個關鍵技術,包括正溫度系數電阻、無引線電阻、氧化電阻、高頻電阻、琺瑯繞線電阻、精密電阻以及電子連接器(線)製造。這些關鍵技術的發展將推動被動電子元件製造領域的未來發展趨勢。

正溫度系數電阻是一種特殊的電阻,其電阻值在溫度上升時會增加。這種正溫度系數的特性使得它在測量和控制電流的應用中得到廣泛使用。未來,隨著對精密控制的需求不斷增加,正溫度系數電阻的精密度和溫度穩定性將成為發展的關鍵。同時,應用於高溫或極低溫環境的正溫度系數電阻也將成為研究的熱點。

無引線電阻是一種現代化的電阻結構,它不使用傳統的金屬引線來連接電阻和電路板,而是通過無引線的電極直接連接。這種結構可以提高電阻的穩定性和可靠性,減少尺寸並提高組裝效率。未來,隨著電子產品尺寸的不斷縮小和高密度集成的需求增加,無引線電阻的研發和應用將成為電子元件製造的一個重要方向。

氧化電阻是一種基於金屬氧化物的電阻,具有高溫穩定性和低溫暈變特性。這種特性使得氧化電阻在高溫環境中的應用非常廣泛,例如汽車電子、航空航天和醫療設備等。未來,隨著對高溫穩定性和耐聚變性能的要求不斷提高,氧化電阻的研究將更加重要。

除了以上介紹的關鍵技術外,高頻電阻、琺瑯繞線電阻、精密電阻和電子連接器(線)製造也是被動電子元件製造領域的重要技術。高頻電阻在無線通信、雷達和衛星通信等領域中扮演著關鍵角色,隨著5G和物聯網技術的發展,對高頻電阻的需求將持續增加。琺瑯繞線電阻和精密電阻在精密測量、溫度控制和儀器儀表等領域有著廣泛的應用。電子連接器(線)製造則是實現電子設備連接和通信的重要環節,隨著智能家居和智慧城市的快速發展,對電子連接器(線)製造的需求也在不斷增加。

總結而言,被動電子元件製造行業將朝著更高精密度、更可靠性和更高性能的方向發展。關鍵技術的不斷創新和應用將推動被動電子元件的發展和應用。我們可以期待在未來,被動電子元件將在各個領域中扮演更加關鍵的角色,為現代化的科技社會提供更好的支持和服務。

Keywords: positive temperature coefficient resistor, leadless resistor, oxide resistor, high-frequency resistor, enamel wire resistor, precision resistor, glass, precision, passive electronic component manufacturing, electronic connector (wire) manufacturing

Title: The Future Development Trends Driven by Key Technologies in Passive Electronic Component Manufacturing

Article:

With the continuous iteration and increasing demand of modern electronic products, passive electronic component manufacturing has become an essential part of the electronics industry. In this article, we introduce several key technologies related to passive electronic components, including positive temperature coefficient resistors, leadless resistors, oxide resistors, high-frequency resistors, enamel wire resistors, precision resistors, and electronic connector (wire) manufacturing. The development of these key technologies will drive the future development trends in the field of passive electronic component manufacturing.

Positive temperature coefficient resistors are special resistors whose resistance increases with temperature. This positive temperature coefficient property makes them widely used in applications involving current measurement and control. In the future, with the increasing demand for precision control, the precision and temperature stability of positive temperature coefficient resistors will be crucial for their development. Additionally, positive temperature coefficient resistors applied in high-temperature or ultra-low-temperature environments will also become a research hotspot.

Leadless resistors are a modern resistor structure that eliminates the use of traditional metal leads for connecting resistors to printed circuit boards. Instead, they directly connect to the board through leadless electrodes. This structure enhances resistance stability and reliability, reduces size, and improves assembly efficiency. In the future, as electronic products continue to shrink in size and the demand for high-density integration increases, the development and application of leadless resistors will become crucial in the field of electronic component manufacturing.

Oxide resistors are resistors based on metal oxides, exhibiting high-temperature stability and low-temperature drift characteristics. This makes them widely used in high-temperature environments, such as automotive electronics, aerospace, and medical equipment. In the future, as the demand for high-temperature stability and resistance to fusion increases, the research on oxide resistors will become more important.

In addition to the aforementioned key technologies, high-frequency resistors, enamel wire resistors, precision resistors, and electronic connector (wire) manufacturing are also important in the field of passive electronic component manufacturing. High-frequency resistors play a crucial role in areas such as wireless communication, radar, and satellite communication. With the development of 5G and IoT technologies, the demand for high-frequency resistors will continue to increase. Enamel wire resistors and precision resistors find extensive applications in precision measurement, temperature control, and instrumentation. Electronic connector (wire) manufacturing is essential for achieving device connectivity and communication. With the rapid development of smart homes and smart cities, the demand for electronic connector (wire) manufacturing is also increasing.

In conclusion, the passive electronic component manufacturing industry will continue to evolve towards higher precision, reliability, and performance. The continuous innovation and application of key technologies will drive the development and application of passive electronic components. We can expect that passive electronic components will play increasingly critical roles in various fields, providing better support and services for a modern technological society.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)