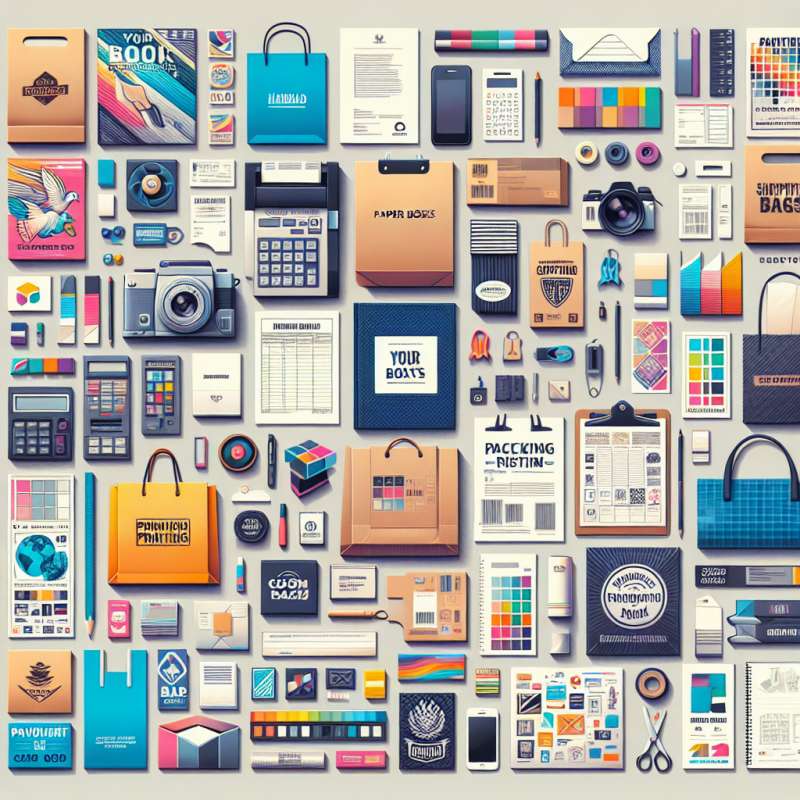

塑膠產業一直是許多國家的重要產業之一,而在這個產業中,製造技術扮演了不可或缺的角色。隨著科技的進步和創新的出現,CNC、伍將和車床等製造技術在塑膠外殼及配件製造、印刷品裝訂及加工以及塑膠袋製品製造等領域中,正發揮著越來越重要的作用。以下我們將討論這些製造技術的未來發展趨勢。

首先,CNC技術在塑膠產業中的應用越來越廣泛。CNC(Computer Numerical Control,電腦數值控制)技術,通過電腦控制機械運動,可以生產出高精度的塑膠製品。隨著電腦軟件和硬件的不斷進步,CNC技術的運作速度和精度也會不斷提高,這將使塑膠製造業能夠生產更多更精確的產品。

其次,伍將和車床等傳統製造技術在塑膠產業中仍然占有重要地位。雖然CNC技術在某些方面具有優勢,但傳統技術仍然有其特殊的應用場景。例如,在生產塑膠外殼和配件時,傳統的伍將和車床技術可以更好地處理一些形狀較為複雜的產品要求。

最後,印刷品裝訂及加工以及塑膠袋製品製造也是塑膠產業中重要的領域。隨著網絡資訊的普及和人們對印刷品和塑膠袋的需求不斷增加,這些領域的發展潛力巨大。將來,印刷品裝訂及加工技術將更加推崇環保和可持續發展的概念,並思考如何減少對環境的影響,例如採用更環保的印刷材料和設備。同樣地,塑膠袋製品製造也將適應環保的要求,開發出更可循環再用和可降解的塑膠袋產品。

綜上所述,CNC、伍將和車床等製造技術在塑膠產業中發揮著重要作用,並且未來將繼續發展和創新。在這個不斷變化的行業中,印刷品裝訂及加工和塑膠袋製品製造也是有著巨大潛力的領域。我們相信,新的技術和趨勢將不斷帶來更高效、環保和創新的解決方案,並推動整個塑膠產業的發展。

關鍵字: CNC, 伍將, 車床, 塑膠外殼及配件製造, 印刷品裝訂及加工, 塑膠袋製品製造

標題: Development Trends in Manufacturing Technology in the Plastic Industry

The plastic industry has always been one of the key industries in many countries, and in this industry, manufacturing technology plays an indispensable role. With advancements in technology and the emergence of innovations, manufacturing technologies such as CNC, lathe, and turning are increasingly important in areas such as plastic casing and accessories manufacturing, print binding and processing, and plastic bag production. In this article, we will discuss the future development trends of these manufacturing technologies.

Firstly, CNC technology is becoming increasingly widespread in the plastic industry. CNC (Computer Numerical Control) technology, which controls machinery movements through computers, can produce plastic products with high precision. As computer software and hardware continue to advance, the speed and accuracy of CNC technology will improve, enabling the plastic manufacturing industry to produce more precise products.

Secondly, traditional manufacturing technologies such as lathe and turning still hold a significant position in the plastic industry. Although CNC technology has its advantages in certain aspects, traditional techniques are better suited for handling more complex product requirements, especially in the production of plastic casings and accessories.

Lastly, print binding and processing, as well as plastic bag manufacturing, are also important sectors in the plastic industry. With the widespread availability of online information and the increasing demand for printed materials and plastic bags, there is enormous potential for development in these areas. In the future, print binding and processing technology will prioritize environmental friendliness and sustainable development, considering how to reduce environmental impact by adopting eco-friendly printing materials and equipment. Similarly, plastic bag manufacturing will also adapt to environmental requirements, developing more recyclable and biodegradable plastic bag products.

In conclusion, CNC, lathe, and turning technologies play a crucial role in the plastic industry and will continue to develop and innovate in the future. In this ever-changing industry, print binding and processing, as well as plastic bag manufacturing, are also areas with great potential. We believe that new technologies and trends will constantly bring more efficient, eco-friendly, and innovative solutions, driving the overall development of the plastic industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)