事務機械設備製造業在全球范圍內都扮演著重要的角色。為了確保產品的質量和可靠性,該行業必須遵循國際標準和取得相應的認證。其中一個關鍵的認證是ISO 9001,它確保企業遵守一個有效的質量管理體系。

精密控制技術在事務機械設備製造業中扮演著重要的角色。利用CNC(Computer Numerical Control)技術,企業可以實現高度的自動化和精度。CNC技術使用電腦控制機器工具,提供更快速和準確的生產過程。這使得企業能夠大規模生產高品質和高精度的產品。

ISO 9001和CNC技術的關聯在於,ISO 9001標準要求企業建立有效的質量管理體系,並且不斷改進。CNC技術的引入可以幫助企業達到更高的精度和可持續的品質。此外,CNC技術還可以提高生產效率和生產能力,同時減少資源浪費。

在美國,AS(Aerospace Standard)是另一個重要的認證標準。事務機械設備製造業也受到AS認證的影響。AS認證確保企業在航空、航天和國防領域擁有符合要求的資質和能力。這種認證對于事務機械設備製造商來說是一個重要的市場競爭優勢。

未來,事務機械設備製造業的發展趨勢將與精密控制技術密不可分。企業需要不斷改進其生產過程,提高品質,減少生產時間和成本。借助CNC技術和ISO 9001認證,企業可以確保產品的高品質和精度。同時,AS認證可以幫助企業開拓新的市場并擴大業務范圍。

綜上所述,事務機械設備製造業必須遵循國際標準和認證來確保產品的質量和可靠性。精密控制技術是實現高品質和高精度產品的關鍵。未來,這些關聯將在業界中持續發展,并在全球范圍內推動事務機械設備製造業的進步。

關鍵字: ISO, CNC, 9001, precision, control, certification, IS, United States, AS, industrial machinery manufacturing

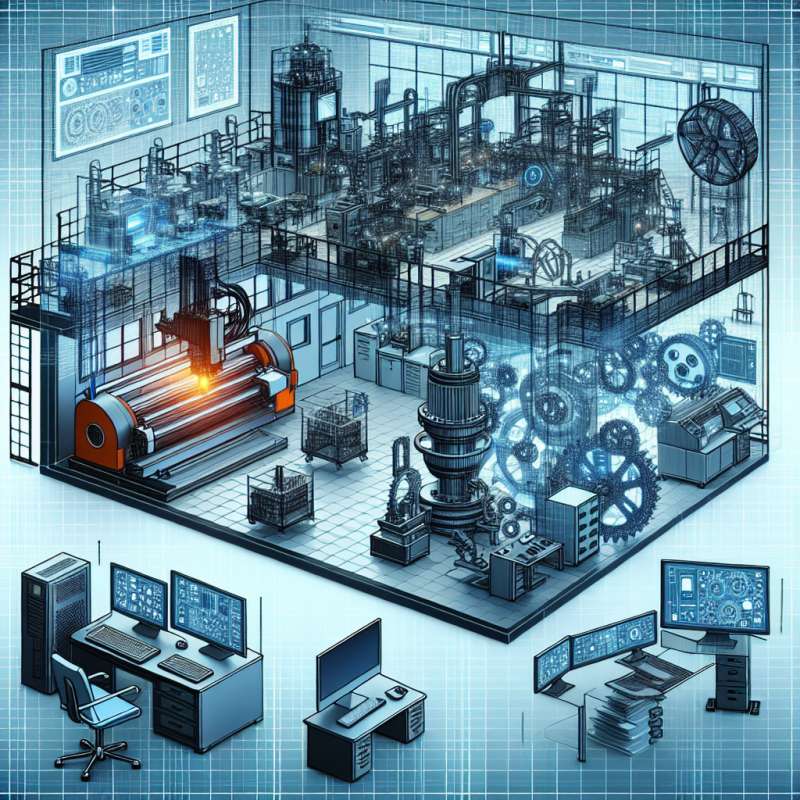

標題: The Future Development Trends of Industrial Machinery Manufacturing and its Connection with Precision Control Technology

Industrial machinery manufacturing plays a crucial role globally. In order to ensure the quality and reliability of their products, this industry needs to adhere to international standards and obtain relevant certifications. One key certification is ISO 9001, which ensures that companies follow an effective quality management system.

Precision control technology plays a significant role in the industrial machinery manufacturing sector. Through Computer Numerical Control (CNC) technology, companies achieve high automation and precision. CNC technology utilizes computer-controlled machine tools, enabling faster and more accurate production processes. This allows companies to mass-produce high-quality and high-precision products.

The connection between ISO 9001 and CNC technology lies in the fact that ISO 9001 standards require companies to establish effective quality management systems and continuously improve them. The introduction of CNC technology helps businesses achieve higher levels of precision and sustainable quality. Additionally, CNC technology enhances production efficiency and capacity while reducing resource waste.

In the United States, AS (Aerospace Standard) is another crucial certification standard that influences industrial machinery manufacturing. The AS certification ensures that companies possess the qualifications and capabilities required in the aerospace, aviation, and defense industries. This certification provides a significant competitive advantage for manufacturers in the industrial machinery sector.

In the future, the development trends of industrial machinery manufacturing will be closely tied to precision control technology. Companies need to continuously improve their production processes, enhance quality, and reduce production time and costs. With CNC technology and ISO 9001 certification, businesses can ensure high-quality products and precision. Meanwhile, AS certification can help expand market opportunities and grow business operations.

In conclusion, industrial machinery manufacturers must adhere to international standards and certifications to ensure product quality and reliability. Precision control technology is the key to achieving high-quality and high-precision products. In the future, these connections will continue to evolve within the industry, driving advancements in industrial machinery manufacturing on a global scale.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)