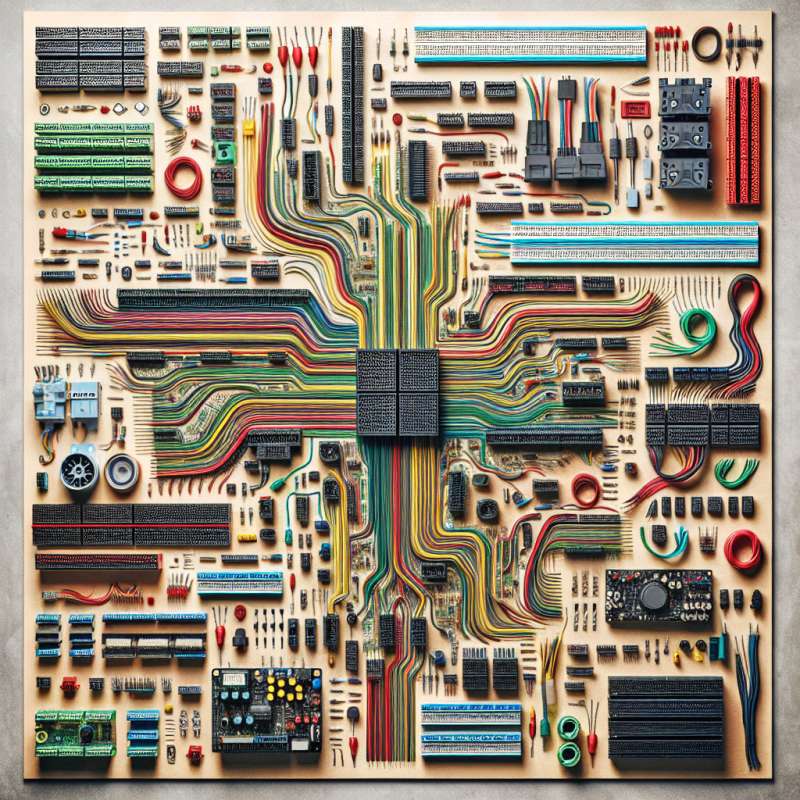

自動化設計在當今科技高速發展的時代中扮演了重要的角色。隨著電子產品和電子連接器(線)製造領域的不斷進步,自動化設計正成為其中的一個關鍵因素。本文將探討自動化設計在這兩個領域中的應用以及未來的發展趨勢。

在電子產品領域,自動化設計可以帶來許多優勢。首先,它可以提高生產效率,降低成本。通過自動控制和自動化技術,生產線的操作可以更加精確和高效,減少了人為因素的干擾。這不僅節省了人力資源,還可以提高生產速度和品質。其次,自動化設計還可以提供更靈活的生產方式。製造業需要快速適應市場需求的變化,而自動化設計可以實現靈活的生產線配置,以應對需求的變化。最後,自動化設計可以提供更高的生產安全性。通過適當的設計和控制系統,可以減少員工接觸到危險物質和危險操作的風險,保護他們的人身安全。

在電子連接器(線)製造領域,自動化設計也起到了重要作用。首先,它可以提高生產精度和一致性。連接器(線)是電子產品必不可少的組件,其發揮著重要的連接功能。通過自動化設計,可以保證連接器(線)的生產精度和一致性,確保連接效果的穩定性和品質的可靠性。其次,自動化設計還可以提高生產速度和效率。連接器(線)的需求量通常很大,因此提高生產速度和效率非常重要。自動化設計可以實現更快速和高效的製造方式,提高生產效益。最後,自動化設計的應用還可以降低生產成本。通過自動化設計,可以減少人力投入和人為因素帶來的錯誤,從而降低生產成本。

未來,自動化設計在電子產品和電子連接器(線)製造領域將繼續發展。隨著科技的進步和自動化技術的成熟,自動化設計的應用將越來越廣泛。未來的自動化設計將更加智能化和靈活化。它將與人工智能和大數據等技術相結合,實現更高的自主性和智能化控制。同時,未來的自動化設計也將更加注重環境保護和節能減排。在製造過程中,將更多地採用節能和環保的技術,減少對環境的影響。此外,自動化設計還將更加注重人性化設計,提供更好的使用者體驗和工作環境。

總之,自動化設計在電子產品和電子連接器(線)製造領域中具有重要的應用價值。它不僅提高了生產效率和品質,還降低了生產成本。隨著未來的發展,自動化設計將不斷加強智能化和環保性,為產業的持續進步和發展做出貢獻。

關鍵字:electronics products, automatic control, automation, design, electrical and electronic connectors (cables) manufacturing

標題:The Application and Future Trends of Automation Design in Electronics Products and Electrical and Electronic Connectors (Cables) Manufacturing

Automation design plays an important role in the era of rapid technological advancement. With the continuous progress in the field of electronics products and electrical and electronic connectors (cables) manufacturing, automation design has become a key factor. This article will explore the application of automation design in these two fields and discuss the future development trends.

In the field of electronics products, automation design brings many advantages. Firstly, it can improve production efficiency and reduce costs. Through automatic control and automation technology, the operation of production lines can be more precise and efficient, reducing the interference of human factors. This not only saves human resources but also improves production speed and quality. Secondly, automation design can provide a more flexible production approach. The manufacturing industry needs to quickly adapt to the changes in market demand, and automation design can achieve flexible production line configurations to respond to such changes. Lastly, automation design can provide higher production safety. By proper design and control systems, the risk of employees being exposed to hazardous substances and dangerous operations can be reduced, protecting their personal safety.

In the field of electrical and electronic connectors (cables) manufacturing, automation design also plays a significant role. Firstly, it can improve production precision and consistency. Connectors (cables) are essential components in electronics products, playing a vital role in ensuring stable connections. Through automation design, the production precision and consistency of the connectors (cables) can be guaranteed, ensuring the stability of the connection effectiveness and reliability of the quality. Secondly, automation design can also increase production speed and efficiency. There is usually a high demand for connectors (cables), so improving production speed and efficiency is critical. Automation design can achieve faster and more efficient manufacturing methods, thus enhancing production benefits. Lastly, the application of automation design can also reduce production costs. By adopting automation design, human labor input and errors caused by human factors can be minimized, thereby lowering production costs.

In the future, automation design will continue to evolve in electronics products and electrical and electronic connectors (cables) manufacturing. With the advancement of technology and the maturity of automation, the application of automation design will become more extensive. Future automation design will be more intelligent and flexible. It will integrate with technologies such as artificial intelligence and big data to achieve higher autonomy and intelligent control. At the same time, future automation design will also focus more on environmental protection and energy conservation. Energy-saving and environmentally friendly technologies will be used more extensively in the manufacturing process to minimize environmental impacts. In addition, automation design will pay more attention to user-friendly design, providing better user experiences and working environments.

In conclusion, automation design has significant application value in the fields of electronics products and electrical and electronic connectors (cables) manufacturing. It not only improves production efficiency and quality but also reduces production costs. With future development, automation design will continue to strengthen in terms of intelligence and environmental friendliness, making contributions to the ongoing progress and development of the industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)