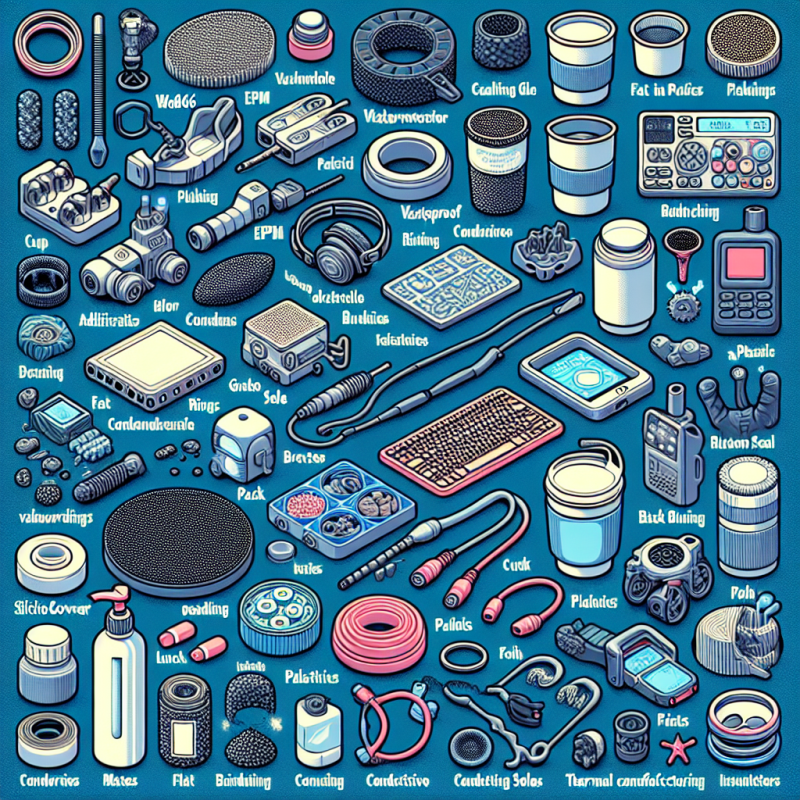

塑膠製造業是現代工業中一個重要且多元化的領域,它包括塑膠的生產、設計和開發。塑膠的應用非常廣泛,從日常生活用品到工業用途都有塑膠的身影。在這個發展迅速的行業中,有幾個非地區性但互相關聯的關鍵字和未來發展趨勢值得關注。

首先是統包商(OEM廠商)。統包商在塑膠製造業中扮演著重要角色,他們不僅提供客戶所需的塑膠製品,還提供相關的設計和開發服務。未來,統包商將更加重視創新和可持續發展。他們將致力於研發環保材料和技術,並將客戶的需求轉化為創新的塑膠製品。

第二個關鍵字是模具開發。模具是塑膠製品的重要組成部分,直接影響其質量和成本。模具開發技術的不斷進步將帶來更高精度和更短的生產週期。未來,模具開發將更加注重自動化和數字化,以提高效率和降低成本。

第三個關鍵字是塑膠射出(Injection Molding)。塑膠射出是最常用的塑膠製造技術之一,它可以生產出各種形狀和尺寸的塑膠製品。未來,塑膠射出技術將更加注重資源節約和環境保護。例如,開發可回收利用的塑膠材料和減少塑膠廢棄物的產生。

另外,塑膠板、管材等製造和工業用橡膠製品製造也是塑膠製造業中一個重要的領域。隨著建築和工業行業的發展,對塑膠板、管材等製品的需求也將持續增長。同時,工業用橡膠製品具有特殊的性能要求,如耐高溫和耐磨損等,未來將更注重研發和應用新型材料。

總的來說,塑膠製造業在未來將朝著環保和創新的方向發展。統包商將主導市場,提供更多創新和可持續發展的塑膠製品。模具開發和塑膠射出技術將不斷進步,提高生產效率和產品品質。塑膠板、管材等製品和工業用橡膠製品將適應建築和工業行業的需求,開發出更具競爭力的產品。

關鍵字: Plastic, OEM Manufacturer, Mold Development, Plastic Injection, Manufacturing of Plastic Sheets, Pipes, Industrial Rubber Products, Manufacture of Unclassified other Plastic Products

標題: Future Trends in the Plastic Manufacturing Industry

The plastic manufacturing industry is an important and diversified sector in modern industry, encompassing the production, design, and development of plastic products. The applications of plastic are extensive, ranging from everyday consumer goods to industrial use. In this rapidly evolving field, there are several non-regional but interrelated keywords and future trends worth noting.

The first keyword is OEM manufacturers. OEM manufacturers play a significant role in the plastic manufacturing industry as they not only provide customers with the required plastic products but also offer related design and development services. In the future, OEM manufacturers will prioritize innovation and sustainable development. They will focus on researching environmentally friendly materials and technologies, transforming customer demands into innovative plastic products.

The second keyword is mold development. Molds are vital components of plastic products, directly impacting their quality and cost. Advances in mold development technology will result in higher precision and shorter production cycles. In the future, mold development will emphasize automation and digitization to enhance efficiency and reduce costs.

The third keyword is plastic injection molding. Plastic injection molding is one of the most commonly used plastic manufacturing techniques, enabling the production of plastic products in various shapes and sizes. In the future, plastic injection molding technology will prioritize resource conservation and environmental protection. For instance, developing recyclable plastic materials and minimizing plastic waste generation.

Additionally, the manufacturing of plastic sheets, pipes, and the production of industrial rubber products are also significant sectors in the plastic manufacturing industry. With the development of the construction and industrial sectors, the demand for plastic sheets, pipes, and related products will continue to grow. Furthermore, industrial rubber products have specific performance requirements such as high temperature resistance and abrasion resistance. Therefore, future efforts will concentrate on researching and applying new materials to meet these needs.

In conclusion, the plastic manufacturing industry is moving towards environmental protection and innovation. OEM manufacturers will dominate the market by providing more innovative and sustainable plastic products. Mold development and plastic injection molding technology will continue to advance, improving production efficiency and product quality. The manufacture of plastic sheets, pipes, and industrial rubber products will adapt to the needs of the construction and industrial sectors, developing more competitive products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)