近年來,工業用橡膠製品製造與EMI(電磁干擾)和ACTI(自動化導電膠構件)領域之間的關聯越來越密切。兩者的相互影響推動了產業的發展,並在未來展現出巨大潛力。

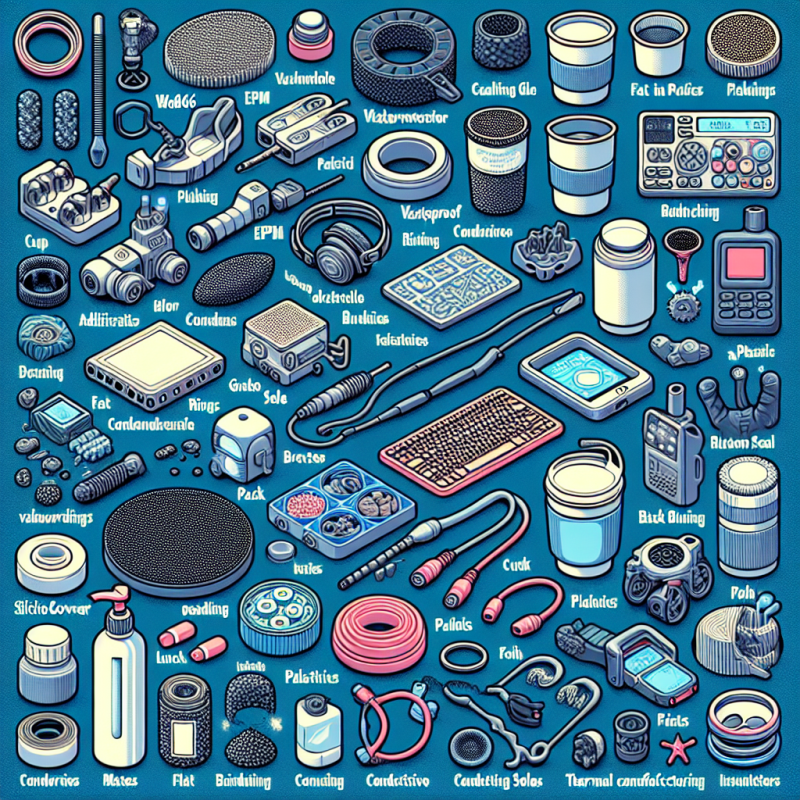

工業用橡膠製品製造是一個多樣化的行業,包括橡膠密封件、橡膠管、橡膠墊板等產品的製造。這些產品在許多行業中被廣泛應用,包括汽車、航空航天、建築、能源等。然而,隨著現代科技的發展,電子設備的使用越來越普及,導致對EMI和ACTI的需求也越來越高。

EMI是指電磁干擾,指的是電子設備之間電磁信號的干擾現象。對於需要電子元件的不受干擾工作環境,EMI成為一個關鍵問題。因此,工業用橡膠製品製造商已經開始研究和開發具有EMI屏蔽效果的橡膠產品。這些產品通常在橡膠中添加特殊的導電材料,以抑制或降低干擾電磁波的穿透。

同樣地,ACTI(自動化導電膠構件)也在工業用橡膠製品製造領域中佔有重要地位。ACTI是將導電性物質添加到橡膠產品中,以使其能與電子設備進行電氣連接。這樣,工業用橡膠製品可以用於傳輸電流、信號和數據,同時具有橡膠的柔韌性和耐用性。

在未來,工業用橡膠製品製造領域將與EMI和ACTI的應用密不可分。隨著科技的進步,電子設備的數量和種類將不斷增加,對於EMI和ACTI的需求將持續增長。因此,工業用橡膠製品製造商需要不斷創新和研發新產品,以滿足不斷變化的市場需求。

同時,隨著綠色環保意識的提高,未來工業用橡膠製品製造將越來越注重環境友好型材料的研發和應用。這需要在保證EMI屏蔽和ACTI功能的同時,減少對環境的負面影響。

總而言之,工業用橡膠製品製造、EMI和ACTI之間存在著密不可分的關聯。隨著科技的發展和市場需求的不斷變化,這種關聯將繼續加強。未來的發展趨勢將包括EMI屏蔽效果更好、ACTI功能更強的工業用橡膠製品的研發和應用。

Keywords: emi, acti, ic, 工業用橡膠製品製造, 化學製品製造

Title: The Connection Between Industrial Rubber Product Manufacturing and EMI and ACTI Fields

Article: In recent years, there has been a growing connection between industrial rubber product manufacturing and the fields of EMI (electromagnetic interference) and ACTI (automated conductive rubber components). The interplay between the two has been driving the industry forward and showing great potential for future development.

Industrial rubber product manufacturing is a diverse industry that includes the production of rubber seals, hoses, gaskets, and more. These products find extensive applications in various industries, including automotive, aerospace, construction, energy, and others. However, with the advancement of modern technology, the widespread use of electronic devices has increased the demand for EMI and ACTI.

EMI, or electromagnetic interference, refers to the disturbance caused by electromagnetic signals between electronic devices. It has become a critical issue for working environments that require electronic components to be free from interference. As a result, industrial rubber product manufacturers have begun researching and developing rubber products with EMI shielding capabilities. These products typically incorporate special conductive materials into the rubber to suppress or reduce the penetration of interfering electromagnetic waves.

Similarly, ACTI (automated conductive rubber components) plays a crucial role in the field of industrial rubber product manufacturing. ACTI involves adding conductive substances to rubber products to enable electrical connections with electronic devices. This allows industrial rubber products to transmit currents, signals, and data while still possessing the flexibility and durability of rubber.

In the future, the connection between industrial rubber product manufacturing and the applications of EMI and ACTI will be inseparable. As technology advances, the number and variety of electronic devices will continue to increase, driving the demand for EMI and ACTI. Consequently, industrial rubber product manufacturers will need to innovate and develop new products to meet evolving market needs.

Moreover, with the growing awareness of environmental sustainability, future industrial rubber product manufacturing will place increasing emphasis on the research and application of environmentally friendly materials. This requires balancing EMI shielding and ACTI functionality while minimizing negative impacts on the environment.

In conclusion, there is an intrinsic connection between industrial rubber product manufacturing, EMI, and ACTI. As technology progresses and market demands evolve, this connection will continue to strengthen. Future development trends will include the development and application of industrial rubber products with improved EMI shielding capabilities and enhanced ACTI functionality.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)