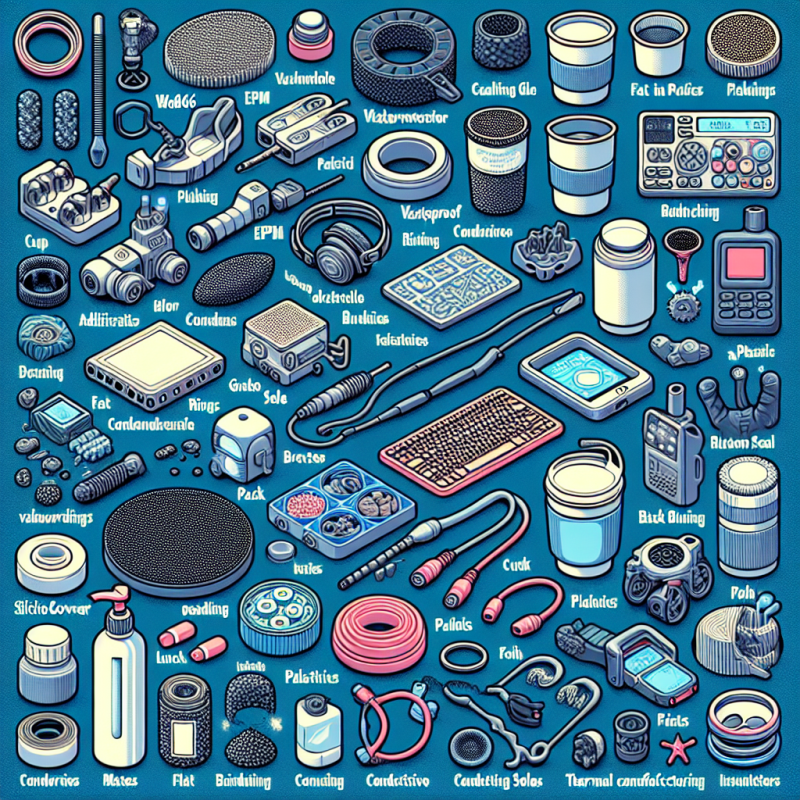

在現代工程機械領域中,O型環、油壓密封、旋轉油封、鐵氟龍墊片等工業用橡膠製品和油封產品扮演著重要的角色。這些密封裝置不僅能防止流體或氣體的外泄,同時還能提供良好的密封效果和機械運動的平穩性。

工程機械油封是指應用於各種工程機械中的油封產品。它們主要包括O型環、油壓密封、旋轉油封和鐵氟龍墊片等多種密封裝置。這些油封產品在工程機械中起著密封液壓系統和維持機械運作平穩的關鍵作用。

未來發展趨勢:

1. 高效能材料的應用: 隨著科學技術的進步,人們將不斷開發和應用新型的高效能材料,例如聚醚類、矽橡膠等。這些新材料具有更好的耐磨損性和適應性,能夠提高工程機械油封的耐用性和使用壽命。

2. 高壓密封技術的突破: 隨著工程機械的發展,對於密封裝置的要求也越來越高。未來,工程機械油封將朝著高壓密封技術的方向發展,以滿足更大壓力和更嚴苛條件下的使用需求。

3. 數字化和智能化應用: 隨著工業4.0時代的到來,工程機械油封將越來越多地應用於數字化和智能化的工程機械設備中。通過傳感器和監控系統的應用,可以實現對油封狀態的監測和預測,提高設備的效率和可靠性。

4. 省能節能和環保意識的提高: 未來,隨著對節能節材和環保的重視,工程機械油封將更加注重節能節材和環保性能。例如,開發更低摩擦系數的油封產品,以減少能源損耗和環境污染。

總之,工程機械油封作為工業用橡膠製品的重要組成部分,在未來將繼續發揮著關鍵的作用。通過高效能材料的應用、高壓密封技術的突破、數字化和智能化應用以及節能節材和環保性能的提升,工程機械油封將不斷提高其性能和應用領域,以滿足不斷發展的工程機械需求。

關鍵字: O-ring, hydraulic seal, rotary oil seal, PTFE gasket, engineering machinery oil seal

標題: Future Development Trends of Engineering Machinery Oil Seals

In the field of modern engineering machinery, industrial rubber products such as O-rings, hydraulic seals, rotary oil seals, PTFE gaskets, and other oil seal products play a crucial role. These sealing devices not only prevent fluid or gas leakage but also provide excellent sealing effects and smooth mechanical movements.

Engineering machinery oil seals are a type of oil seal product used in various engineering machinery. They mainly include O-rings, hydraulic seals, rotary oil seals, and PTFE gaskets. These oil seal products play a key role in sealing hydraulic systems and ensuring smooth machinery operations.

Future development trends:

1. Application of high-performance materials: With advancements in science and technology, new high-performance materials such as polyether and silicone rubber will be continuously developed and applied. These new materials have better wear resistance and adaptability, improving the durability and lifespan of engineering machinery oil seals.

2. Breakthrough in high-pressure sealing technology: As engineering machinery continues to develop, the requirements for sealing devices are becoming increasingly demanding. In the future, engineering machinery oil seals will evolve towards high-pressure sealing technology to meet the needs of higher pressures and more stringent conditions.

3. Digitalization and intelligent applications: With the advent of Industry 4.0, engineering machinery oil seals will be increasingly applied in digitalized and intelligent engineering machinery equipment. By using sensors and monitoring systems, it is possible to monitor and predict the condition of oil seals, enhancing equipment efficiency and reliability.

4. Increased focus on energy conservation and environmental awareness: In the future, with a greater emphasis on energy conservation and environmental protection, engineering machinery oil seals will prioritize energy-saving and environmentally friendly performance. For example, developing oil seal products with lower friction coefficients to reduce energy consumption and environmental pollution.

In conclusion, as an important component of industrial rubber products, engineering machinery oil seals will continue to play a crucial role in the future. Through the application of high-performance materials, breakthroughs in high-pressure sealing technology, digitalization and intelligent applications, and improvements in energy conservation and environmental performance, engineering machinery oil seals will continuously enhance their performance and application areas to meet the evolving demands of engineering machinery.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)