近年來,隨著節能綠色概念的普及,冰水機和研磨機的使用在木材加工行業中呈現快速增長的趨勢。這是由於這些機械設備的節能發熱器技術的應用,為加工業者提供了更節能、高效的解決方案。

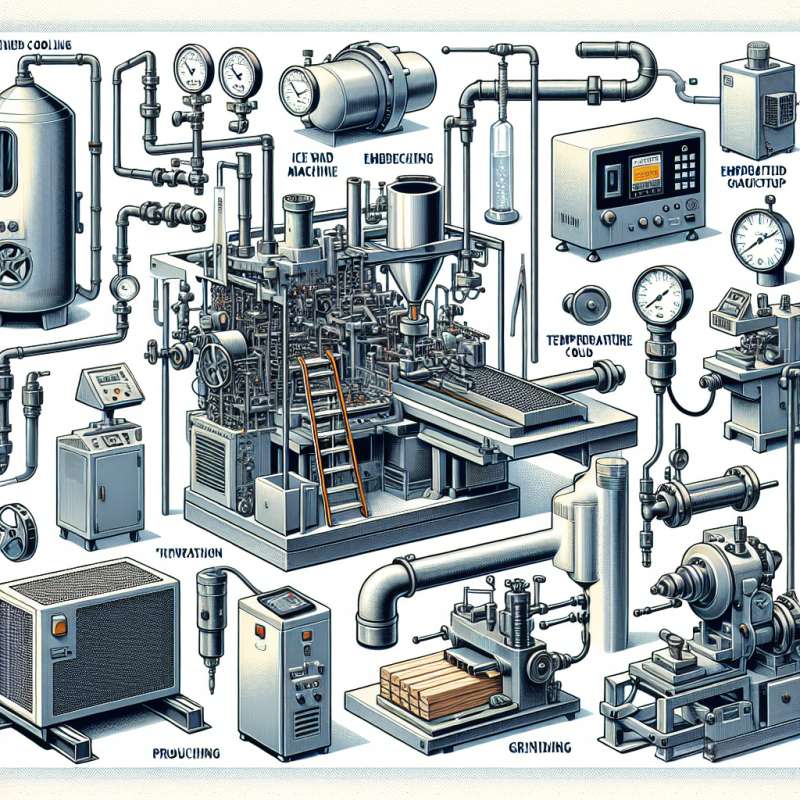

冰水機,作為一種廠房冷卻設備,常用於長時間運轉的機械設備的冷卻系統。在木材加工行業中,冰水機的使用率明顯增加,主要是由於原料木材在加工過程中會產生大量的熱量,這也需要消耗大量的能源。冰水機的應用可以有效地降低原料木材的工作溫度,提高加工效率,同時也節省了能源成本,符合現代節能環保的要求。

而研磨機作為木材加工行業中常見的設備之一,經常用於對木材進行切割、研磨等處理。近年來,研磨機在其技術改進方面取得了許多進展,特別是在機械的節能效果上。研磨機的節能發熱器技術的應用,可以大幅降低設備在運轉過程中的能耗,同時也提高了加工過程的穩定性和效能。這種節能技術不僅為製造商提供了更具競爭力的產品,同時也為市場帶來新的需求增長。

隨著節能概念的日益重要,越來越多的木材加工行業選擇了配備節能發熱器的冰水機和研磨機。這不僅降低了能源成本,同時也提高了設備的運行效率和加工品質。考慮到這些優勢,市場對於節能發熱器技術應用的需求也呈現持續增長的趨勢。

總之,在木材加工行業中,冰水機和研磨機的節能發熱器技術應用正在成為市場需求增長的關鍵。製造商和批發商不僅需關注技術的創新和優化,也需要瞭解市場的趨勢和需求,以滿足客戶的需求並提供更可靠、節能、高效的製造和生產製造設備。

關鍵字: Ice-water machine, Grinding machine, Energy-saving heater, Wholesale of woodworking machinery

Title: Growing Market Demand for Ice-water Machines and Grinding Machines in Woodworking Industry thanks to Energy-saving Heater Technology

Article: In recent years, with the popularization of energy-saving and green concepts, the use of ice-water machines and grinding machines has shown rapid growth in the woodworking industry. This is due to the application of energy-saving heater technology in these machinery equipments, providing woodworkers with more energy-efficient and efficient solutions.

Ice-water machines, as cooling equipment in factories, are commonly used in the cooling system of machinery that operates for long periods of time. In the woodworking industry, the utilization rate of ice-water machines has significantly increased. This is mainly because the raw materials of wood generate a large amount of heat during processing, which also requires a significant amount of energy consumption. The application of ice-water machines can effectively lower the working temperature of the raw materials, improve processing efficiency, and save energy costs, meeting the requirements of modern energy-saving and environmental protection.

As one of the common equipments in the woodworking industry, grinding machines are often used for cutting, grinding, and processing wood. In recent years, grinding machines have made significant progress in their technical improvements, especially in terms of energy efficiency. The application of energy-saving heater technology in grinding machines can significantly reduce the energy consumption during operation while also improving the stability and efficiency of the processing process. This energy-saving technology not only provides manufacturers with more competitive products but also brings new demand growth to the market.

With the increasing importance of energy-saving concepts, more and more woodworking industries are choosing ice-water machines and grinding machines equipped with energy-saving heaters. This not only reduces energy costs but also improves equipment operating efficiency and processing quality. Considering these advantages, the market demand for the application of energy-saving heater technology is showing a continuous growth trend.

In summary, in the woodworking industry, the application of energy-saving heater technology in ice-water machines and grinding machines is becoming a key factor in increasing market demand. Manufacturers and wholesalers need to focus not only on technological innovation and optimization but also understand market trends and demands to meet customer needs and provide more reliable, energy-efficient, and efficient manufacturing and production equipment.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)