金屬結構製造一直是建築和工業領域中重要的一環。這個行業包括容器、鍋爐、化工機械設備製造、食品、飲料及菸草製作用機械設備製造和金屬結構及建築組件批發等不同領域。這篇文章將討論金屬結構製造的未來發展趨勢以及相關的關鍵字。

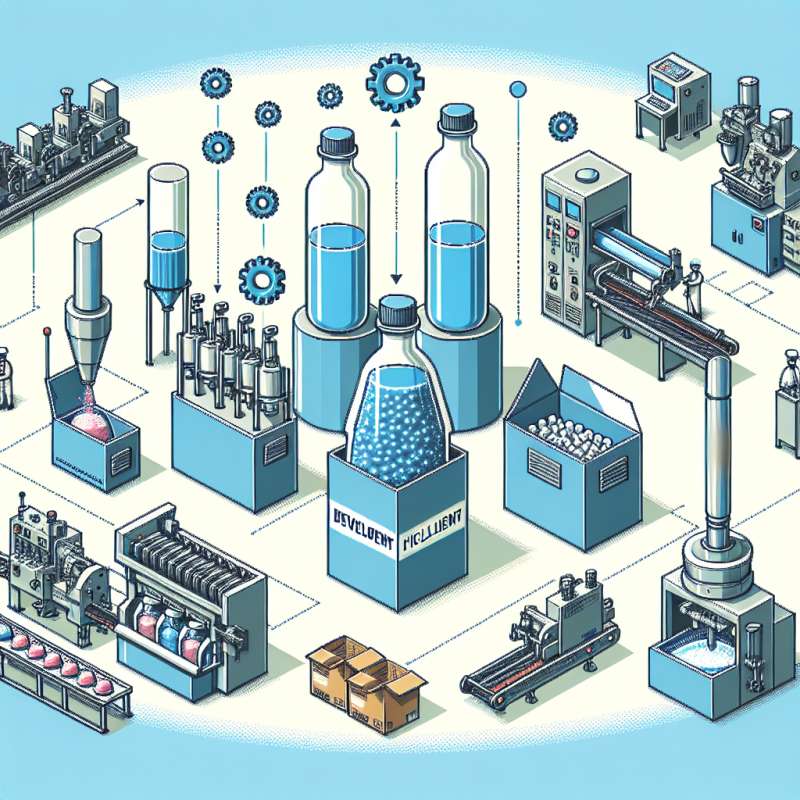

未來金屬結構製造領域的關鍵字之一是自動化。在製造過程中,導入更多自動化技術可以提高生產效率,降低人力成本和錯誤率。自動化設備可以用來製造容器、鍋爐和其他金屬結構,並且可以實現更高的生產能力和品質控制。

另一個關鍵字是數字化製造。隨著科技的進步,數字化製造將成為金屬結構製造的重要趨勢。通過使用先進的設備和軟體,製造商可以更準確地設計和製造金屬結構,並實現更高的生產效率和品質控制。

未來金屬結構製造領域的另一個重要趨勢是可持續性。隨著對環境的關注不斷增加,金屬結構製造商將需要尋找更環保的製造方法和材料。例如,使用再生金屬材料可以降低對有限自然資源的需求。製造商還可以尋找更節能的製造方法,以減少能源消耗和碳排放。

總而言之,未來金屬結構製造領域將朝著自動化、數字化和可持續性的方向發展。這些關鍵字將成為該行業的重要趨勢,並將對製造商和整個供應鏈產生深遠的影響。

關鍵字: Metal Fabrication, Boilers, Manufacturing of Chemical Machinery, Wholesale of Metal Structures and Building Components

標題: Future Trends in Metal Fabrication Industry

Metal fabrication has always been an important aspect of the construction and industrial sectors. This industry encompasses various fields such as manufacturing of containers, boilers, chemical machinery, food, beverage, and tobacco processing equipment, as well as the wholesale of metal structures and building components. This article will discuss the future trends in metal fabrication and its related keywords.

One of the keywords in the future of metal fabrication is automation. Introducing more automation technologies in the manufacturing process can improve production efficiency, reduce labor costs, and minimize error rates. Automated equipment can be used to manufacture containers, boilers, and other metal structures, achieving higher production capacity and quality control.

Another key keyword is digital manufacturing. With advancements in technology, digital manufacturing is set to be a significant trend in the metal fabrication industry. By utilizing advanced equipment and software, manufacturers can design and fabricate metal structures with greater accuracy, achieving higher production efficiency and quality control.

Sustainability is another important trend in the future of metal fabrication. With increasing environmental concerns, metal fabricators will need to seek more environmentally friendly manufacturing methods and materials. For instance, using recycled metal materials can reduce the demand for finite natural resources. Manufacturers can also explore energy-efficient manufacturing methods to reduce energy consumption and carbon emissions.

In conclusion, the future of metal fabrication will revolve around trends such as automation, digitalization, and sustainability. These keywords will shape the industry and have significant impacts on manufacturers and the entire supply chain.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)