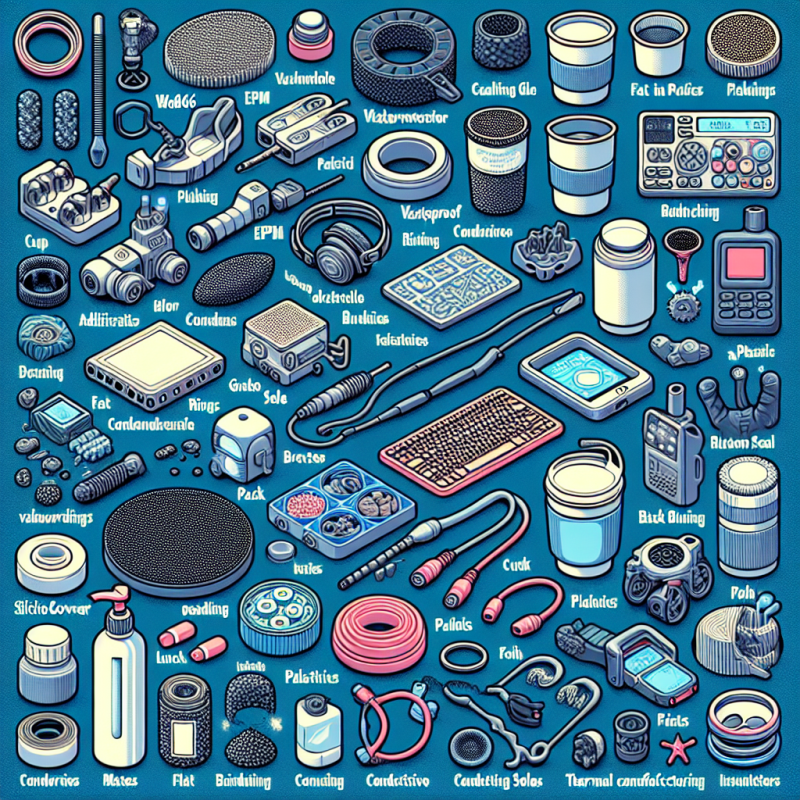

近年來,密封件、防塵套和金屬模具製造在橡膠製品製造業中扮演著關鍵的角色。這些產品的需求增長主要來自於工業用橡膠製品的製造商和綜合商品批發商。

橡膠製品製造業的關鍵產品之一是密封件。密封件具有預防液體或氣體從裝配件之間進出的功能,廣泛應用於機械、汽車、航空航天等領域。隨著這些行業的增長,對密封件的需求也在不斷增加。市場上的密封件主要有橡膠密封件、矽膠密封件和氟碳橡膠密封件。其中,矽膠密封件和氟碳橡膠密封件在高溫和耐腐蝕性能方面具有優勢,受到廣泛的青睞。

除了密封件外,防塵套也是橡膠製品製造業中的重要組件。防塵套的主要功能是阻擋塵埃、液體和其他雜質進入機械裝配體,確保其正常運行。防塵套廣泛應用於汽車、航空航天、電子設備等行業。市場上的防塵套材料主要有橡膠和矽膠,具有靈活性和耐用性。

另一個關鍵的市場需求增長來源是金屬模具製造。金屬模具主要用於橡膠製品的製造,如車輪、密封件和防塵套等。金屬模具的質量和製造工藝對於最終產品的質量至關重要。因此,橡膠製品製造商對金屬模具的需求也在增加。金屬模具製造需要精密加工和高技術水準,因此,優質的金屬模具製造商在市場上具有競爭力。

總的來說,橡膠製品製造業的關鍵產品密封件、防塵套和金屬模具製造是市場需求增長的重要動力。隨著工業領域的發展,對這些產品的需求將會持續增加。同時,這些產品的品質和技術也將成為業內競爭的關鍵因素。

關鍵字: Seal, Dust cover, Air hydraulic pressure, Rubber product manufacturing, Metal mold manufacturing

標題: The Key to Rubber Product Manufacturing: Seal, Dust Cover, and Metal Mold

In recent years, seal, dust cover, and metal mold manufacturing have played a crucial role in the rubber product manufacturing industry. The demand for these products primarily comes from manufacturers of industrial rubber products and wholesale distributors.

One of the key products in the rubber product manufacturing industry is seal. Seals are designed to prevent liquids or gases from entering or exiting between assemblies and are widely used in machinery, automotive, aerospace, and other industries. With the growth of these industries, the demand for seals continues to increase. The market offers various types of seals, including rubber seals, silicone seals, and fluorocarbon rubber seals. Silicone and fluorocarbon rubber seals, in particular, have advantages in high-temperature and corrosion resistance, making them popular choices.

In addition to seals, dust covers are also important components in the rubber product manufacturing industry. Dust covers mainly function to prevent dust, liquids, and other impurities from entering mechanical assemblies, ensuring their normal operation. Dust covers are widely used in automotive, aerospace, and electronic equipment industries. The materials used for dust covers are primarily rubber and silicone, which offer flexibility and durability.

Another key driver of market demand growth is metal mold manufacturing. Metal molds are mainly used in the manufacturing of rubber products such as wheels, seals, and dust covers. The quality and manufacturing process of metal molds are critical to the quality of the final products. Therefore, rubber product manufacturers have an increasing demand for metal molds. Metal mold manufacturing requires precision machining and high technical expertise, making quality metal mold manufacturers competitive in the market.

In conclusion, seal, dust cover, and metal mold manufacturing are key products in the rubber product manufacturing industry, driving market demand growth. With the development of industrial sectors, the demand for these products will continue to rise. At the same time, the quality and technology of these products will be crucial factors in industry competition.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)