隨著現代科技的發展,工業領域中的電鍍技術已經成為不可或缺的一環。其中,化學鍍、電子電鍍和工業電鍍是目前最常見且廣泛應用的技術。未來,這些技術將朝著更環保、高效和創新的方向發展。

在化學鍍方面,未來的發展趨勢將集中在研發更環保的鍍液和藥劑。傳統的鍍液通常包含有害物質,對環境和人體健康造成威脅。因此,科學家和工程師正在努力尋找替代鍍液,例如水性鍍液和無機鍍液,以減少對環境的影響。同時,他們還致力於提高鍍膜的質量和穩定性,以滿足不同工業領域的需求。

在電子電鍍方面,未來的發展趨勢將集中在提高鍍膜的導電性和耐久性。隨著5G、物聯網和人工智能等技術的發展,對於電子元件的需求也在不斷增加。因此,電子電鍍領域需要尋找更高效和可靠的鍍膜技術,以滿足這些新興技術的要求。此外,隨著可穿戴裝置和柔性顯示器等產品的興起,柔性電子電鍍技術也將成為未來的發展重點。

在工業電鍍方面,未來的發展趨勢將集中在節能降耗和提高產能。工業電鍍是許多製造業中不可或缺的工藝,但同時也消耗大量的能源和資源。未來,工程師將致力於研發更節能高效的電鍍設備和技術,以減少環境影響並提高產能。此外,智能工業電鍍技術也將逐漸發展起來,例如使用物聯網和人工智能技術實現電鍍過程的監控和調整。

綜上所述,工業電鍍、化學鍍和電子電鍍是未來工業領域中具有關聯性且非地區性的關鍵技術。未來,這些技術將朝著更環保、高效和創新的方向發展,並應用於各個工業領域中。我們期待著這些技術的不斷發展和創新,為工業領域帶來更大的突破和進步。

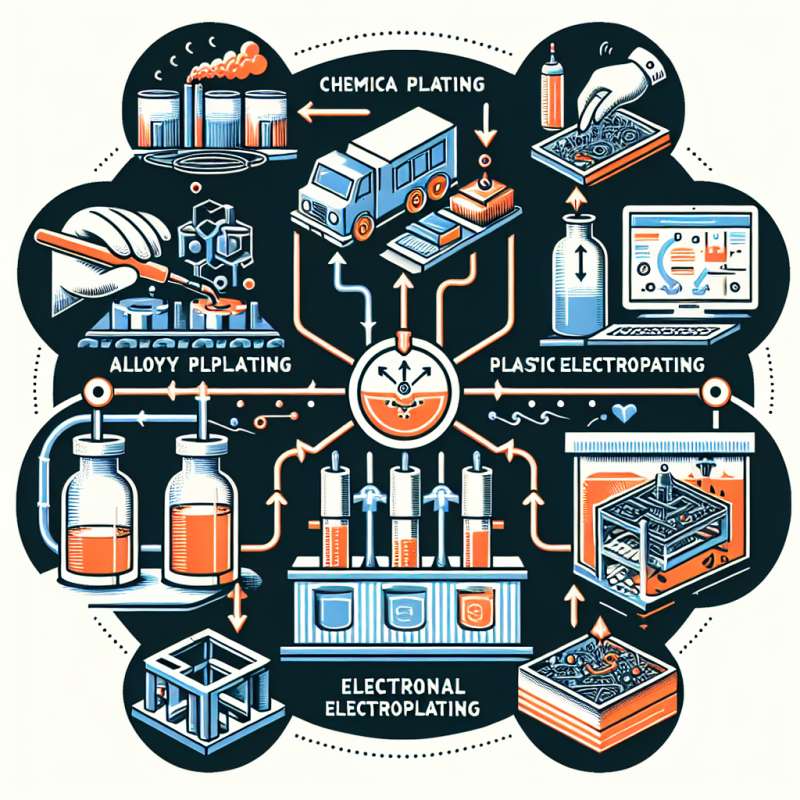

關鍵字:Chemical plating, alloy electroplating, plastic electroplating, post-treatment chemicals, industrial electroplating, electronic electroplating, chemical raw material manufacturing

標題:Future Development Trends and Innovations in Industrial Electroplating

With the advancement of modern technology, electroplating has become an indispensable part of the industrial sector. Among them, chemical plating, electronic electroplating, and industrial electroplating are currently the most common and widely used techniques. In the future, these technologies will develop towards being more environmentally friendly, efficient, and innovative.

In regards to chemical plating, future development trends will focus on the research and development of more environmentally friendly plating solutions and chemicals. Traditional plating solutions often contain hazardous substances, posing a threat to the environment and human health. Therefore, scientists and engineers are working tirelessly to find alternative solutions such as water-based plating solutions and inorganic plating solutions to reduce environmental impact. At the same time, efforts are also being made to improve the quality and stability of the deposited coatings to meet the demands of different industrial sectors.

In terms of electronic electroplating, future development trends will focus on enhancing the conductivity and durability of the deposited coatings. With the advancements in technologies such as 5G, the Internet of Things, and artificial intelligence, the demand for electronic components is constantly increasing. Therefore, the field of electronic electroplating needs to seek more efficient and reliable coating technologies to meet the requirements of these emerging technologies. Additionally, with the rise of wearable devices and flexible displays, flexible electronic electroplating techniques will also become a focus of future development.

Regarding industrial electroplating, future development trends will concentrate on energy conservation, reducing consumption, and increasing production capacity. Industrial electroplating is an essential process in many manufacturing industries but simultaneously consumes a significant amount of energy and resources. In the future, engineers will focus on developing energy-efficient electroplating equipment and technologies to reduce environmental impact and increase production capacity. Additionally, smart industrial electroplating technologies will gradually emerge, such as using the Internet of Things and artificial intelligence to monitor and adjust the electroplating processes.

In conclusion, industrial electroplating, chemical plating, and electronic electroplating are non-regional and interconnected key technologies in the future industrial sector. Moving forward, these technologies will develop towards being more environmentally friendly, efficient, and innovative, being applied in various industrial sectors. We look forward to the continuous development and innovation of these technologies, bringing about greater breakthroughs and advancements in the industrial field.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)