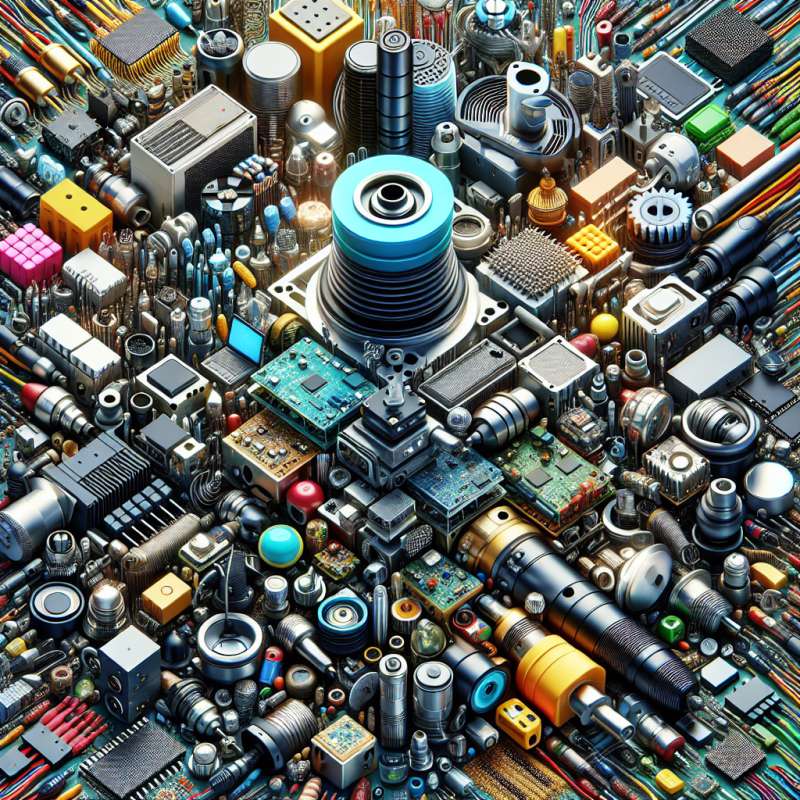

專業沖壓在製造業中扮演著重要角色,尤其是在連接器的製造過程中。連接器是電子產品中不可或缺的組件之一,它們負責連接不同零件和設備,確保電流的穩定傳輸。隨著科技的快速發展和日益普及,連接器製造業正處於蓬勃發展的階段。

金屬沖壓技術在連接器製造過程中扮演關鍵角色。金屬沖壓是一種以板材為基材,利用模具施加力量將其塑形成所需的形狀。連接器的製造需要高度精密的模具,以及具有持久耐用和良好導電性能的金屬材料。連接器的成功運作取決於沖壓過程中的精確度和結構品質。

隨著連接器的需求不斷增加,連續沖壓模具成為製造業中的關鍵技術。連續沖壓模具能夠連續、高效地塑形金屬材料,提高生產效率並保證一致的品質。連續沖壓精密的模具技術不僅能夠應對大批量生產,同時還能夠應對不同尺寸和形狀的連接器需求。

在電子產品的製造中,電子連接器尤為重要。它們是電子產品中各個零件之間的橋樑,確保訊號和電力的順利傳遞。隨著便攜式和無線電子產品的普及,電子連接器的需求也不斷增加。

電腦週邊設備製造和視聽電子產品製造是連接器製造業的主要應用領域之一。現代的電腦和視聽設備需要各種連接器,以實現與其他設備的連接和互動。隨著人們對高畫質和多媒體體驗的追求,這些領域將持續需要高品質和高性能的連接器。

未來,連接器製造業將繼續朝著更高的精密度和更高的性能要求發展。隨著科技的進步,連接器需要更小、更輕巧,同時具有更好的導電性和耐用性。

總的來說,連接器製造業具有廣闊的市場前景和潛在的發展機會。專業沖壓、連續沖壓模具和連接器製造技術的不斷進步將為這個行業帶來更多創新和競爭力。隨著無線通訊技術、智能家居和物聯網的迅速發展,連接器製造業將繼續扮演關鍵角色,推動科技的進步。

關鍵字: Professional stamping, connectors, medical, metal stamping, progressive die stamping, continuous stamping precision, electronics, components, manufacturing of electronic connectors (wires), manufacturing of computer peripheral equipment, manufacturing of audio-visual electronic products

Title: Prospects and Trends in the Connector Manufacturing Industry

Article: Professional stamping plays an important role in the manufacturing industry, especially in the production of connectors. Connectors are essential components in electronic products, responsible for connecting different parts and devices to ensure stable current transmission. With rapid technological advancements and increasing popularity, the connector manufacturing industry is in a thriving phase.

Metal stamping technology plays a crucial role in the manufacturing process of connectors. Metal stamping is a technique that uses molds to apply force to sheet metal and shape it into the desired form. The manufacturing of connectors requires highly precise molds and durable metal materials with good conductivity. The successful operation of connectors depends on the accuracy and structural quality during the stamping process.

As the demand for connectors continues to rise, progressive die stamping becomes a key technology in the manufacturing industry. Progressive die stamping allows for continuous and efficient shaping of metal materials, improving production efficiency and ensuring consistent quality. The precision of continuous stamping molds enables the handling of large-scale production while accommodating different sizes and shapes of connectors.

In the manufacturing of electronic products, electronic connectors are particularly important. They serve as bridges between various parts of electronic products, ensuring smooth transmission of signals and power. With the popularity of portable and wireless electronic devices, the demand for electronic connectors is constantly increasing.

Manufacturing of computer peripheral equipment and audio-visual electronic products is one of the main application areas of connector manufacturing. Modern computers and audio-visual devices require various connectors to facilitate connection and interaction with other devices. As people pursue high-definition and multimedia experiences, these sectors will continue to require high-quality and high-performance connectors.

In the future, the connector manufacturing industry will continue to develop towards higher precision and performance requirements. With technological advancements, connectors need to be smaller, lighter, while having better conductivity and durability.

Overall, the connector manufacturing industry offers vast market prospects and potential development opportunities. Advances in professional stamping, progressive die stamping, and connector manufacturing technology will bring more innovation and competitiveness to this industry. With the rapid development of wireless communication technology, smart homes, and the Internet of Things, the connector manufacturing industry will continue to play a key role in driving technological advancements.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)