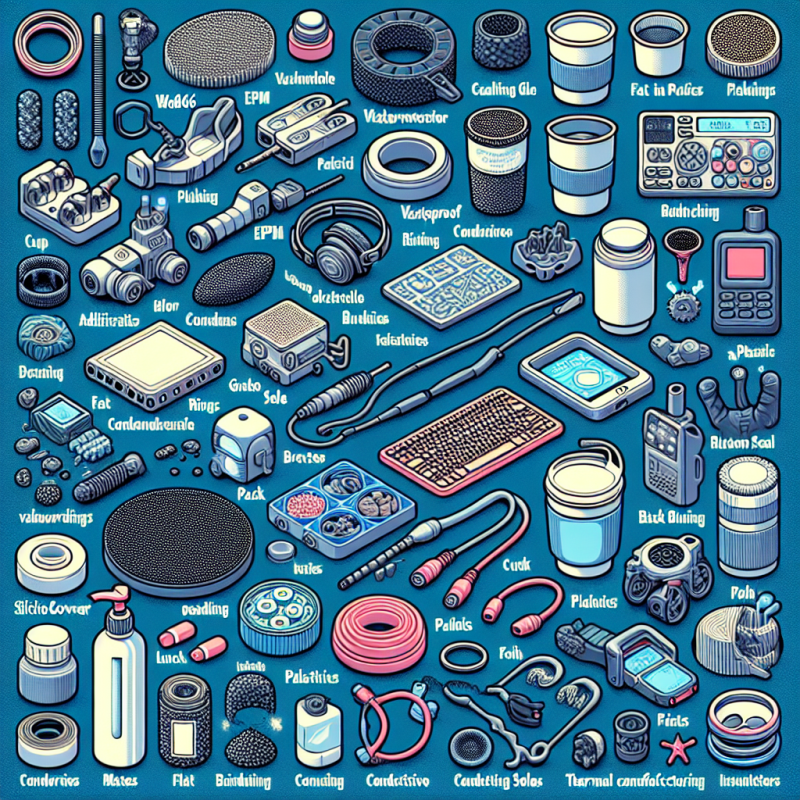

在工業製造領域中,使用無矽無硫材料的需求逐漸增加。隨著技術的不斷進步與市場對產品質量和環境友好的要求提高,無矽無硫材料成為一種受到關注的方向。導電泡棉、精密沖型加工和絕緣材料等材料的應用正在成為未來工業用橡膠製品製造的趨勢。

無矽無硫材料的主要特點是不含有矽和硫元素,這使得它在不同工業應用中具有更多的優勢。例如,無矽無硫材料的使用可以減少矽橡膠成型過程中有害物質的排放,同時提高產品的品質和性能。這種材料被廣泛應用於工業用橡膠製品製造過程中的絕緣材料、導電泡棉和精密沖型加工等領域。

其中,導電泡棉是一種具有良好導電性和絕緣性的材料。它可以用於電子產品的保護和導電隔離,并且在高溫和高壓環境下表現出色。例如,在汽車工業中,導電泡棉被廣泛應用於汽車電池的絕緣和連接。這種材料的不斷發展和創新將有助於未來車輛電氣系統在性能和安全性方面的提升。

另一方面,精密沖型加工技術正在成為工業用橡膠製品製造中的關鍵步驟。精密沖型加工能夠生產出具有高精度和複雜形狀的產品。這種技術的發展使得無矽無硫材料在工業用橡膠製品製造中的應用更加靈活和多樣化。

絕緣材料也是工業用橡膠製品製造中的關鍵材料。絕緣材料可以在高溫和高電壓環境下保護產品的性能和安全性。無矽無硫材料的應用使得絕緣材料更加環保且擁有更高的性能。

總而言之,無矽無硫材料在工業用橡膠製品製造中的應用前景非常廣闊。導電泡棉、精密沖型加工和絕緣材料等材料的發展將有助於提高產品的性能和品質,同時減少對環境的影響。隨著技術不斷進步,這些關鍵材料將繼續在工業製造領域中扮演重要角色,推動產業的發展。

關鍵字: Non-silicone non-sulfur, Conductive foam, Precision stamping, Insulation materials, Industrial rubber product manufacturing

標題: Future Trends in Industrial Rubber Product Manufacturing with Non-Silicone Non-Sulfur Materials

Within the industrial manufacturing sector, the demand for non-silicone non-sulfur materials is gradually increasing. With advancing technology and growing market demands for product quality and environmental friendliness, non-silicone non-sulfur materials have become an area of focus. The application of conductive foam, precision stamping, and insulation materials is emerging as a future trend in the manufacturing of industrial rubber products.

Non-silicone non-sulfur materials are characterized by the absence of silicon and sulfur elements, providing them with numerous advantages in various industrial applications. For instance, the use of these materials can reduce harmful emissions during silicone rubber molding processes while improving product quality and performance. Such materials find wide application in areas such as insulation materials, conductive foam, and precision stamping in the manufacturing of industrial rubber products.

Among these, conductive foam is a material that exhibits excellent conductivity and insulation properties. It can be used for protection and conductive isolation in electronic products, performing exceptionally well under high temperature and pressure conditions. For example, in the automotive industry, conductive foam is widely used for insulation and connection in automotive batteries. Ongoing development and innovation in this material will contribute to enhancing the performance and safety aspects of future vehicle electrical systems.

Furthermore, precision stamping technology is becoming a critical step in the manufacturing of industrial rubber products. Precision stamping enables the production of high-precision and intricately shaped products. The development of this technology allows for more flexible and diverse applications of non-silicone non-sulfur materials in the manufacturing of industrial rubber products.

Insulation materials also play a vital role in the manufacturing of industrial rubber products. These materials protect product performance and safety under high temperature and voltage conditions. The application of non-silicone non-sulfur materials makes insulation materials more environmentally friendly and enhances their performance.

In conclusion, the prospects for non-silicone non-sulfur materials in the manufacturing of industrial rubber products are vast. The development of conductive foam, precision stamping, insulation materials, and other related materials will contribute to improving product performance and quality while reducing environmental impact. As technology continues to advance, these key materials will continue to play essential roles in the industrial manufacturing sector, driving industry growth.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)