隨著科技的進步和工業的發展,位移檢測已成為許多行業的重要工具。材料試驗是一種常見的位移檢測應用領域,它在確保產品質量和安全性方面扮演著關鍵角色。然而,傳統的材料試驗方法存在效率低下、成本高昂以及人為誤差等問題。

在未來的發展趨勢中,自動化將成為材料試驗的主流。通過引入自動化技術,可以實現試驗過程的持續監控和控制,提高測量的準確性和一致性。自動化還可以大幅減少人為誤差,提高工作效率。此外,自動化還能夠有效降低試驗成本,提升產品的競爭力。

此外,事務機械設備製造和抽風機製造也是未來的關鍵發展領域。隨著建築物、工廠和辦公室等室內環境對空氣品質的要求越來越高,抽風機的應用日益普及。然而,傳統抽風機存在噪音大、能耗高和維護困難等問題。為了滿足環境保護和節能的需求,抽風機製造需要引入新技術和創新材料。

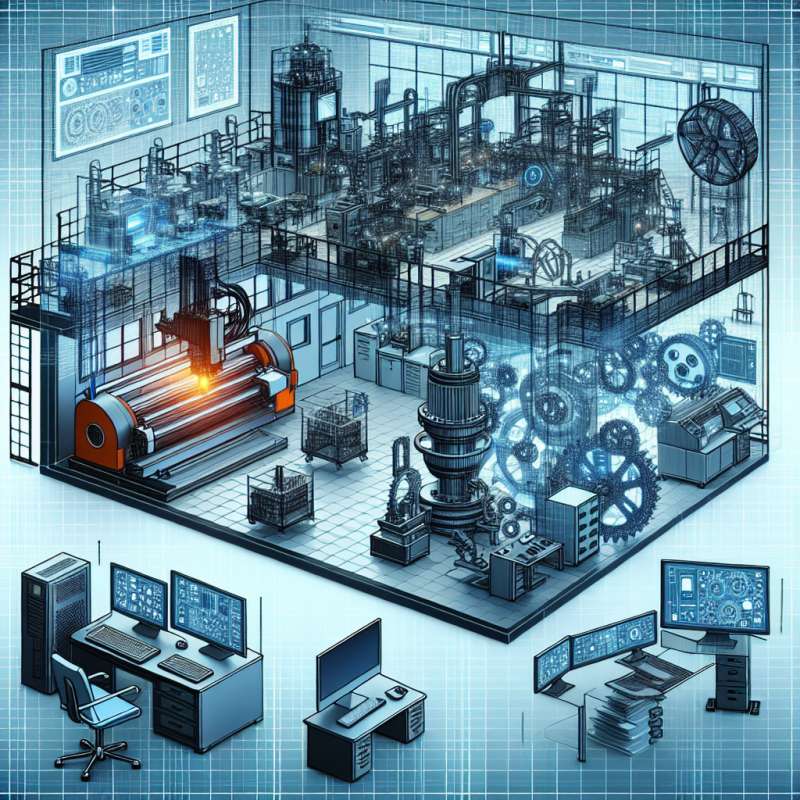

事務機械設備製造是一個能夠提供高效、可靠且符合現代化需求的工業解決方案的領域。將自動化技術應用於事務機械設備製造,可以提高產品的性能和生產效率。例如,自動化裝配線和智能監控系統可以實現更快速的生產速度和更高的生產質量。未來,事務機械設備製造將朝著更高效、可持續、智能和綠色的方向發展。

綜上所述,隨著位移檢測、材料試驗、自動化、事務機械設備製造和抽風機製造等領域的不斷發展和創新,未來的趨勢將朝著更加自動化、高效、可持續和智能的方向發展。這些趨勢將在提高生產效率、降低成本和改善產品質量等方面產生巨大的影響,並為相關行業帶來更多的發展機遇。

關鍵字: Displacement detection, Material testing, Automation, Manufacturing of office machinery equipment, Manufacturing of ventilation fans

標題: Future Trends in Automated Material Testing and Ventilation Fan Manufacturing

With the advancement of technology and industrial development, displacement detection has become an essential tool in many industries. Material testing is a common application area for displacement detection, playing a crucial role in ensuring product quality and safety. However, traditional material testing methods suffer from inefficiency, high costs, and human errors.

In the future, automation will dominate the field of material testing. By introducing automation technology, continuous monitoring and control of the testing process can be achieved, improving the accuracy and consistency of measurements. Automation also greatly reduces human errors and improves work efficiency. Additionally, automation can effectively lower testing costs and enhance product competitiveness.

Furthermore, the manufacturing of office machinery equipment and ventilation fans is also a key area for future development. As indoor environments such as buildings, factories, and offices increasingly demand better air quality, the application of ventilation fans is becoming more widespread. However, traditional ventilation fans face challenges such as high noise levels, energy consumption, and maintenance difficulties. To meet the demands of environmental protection and energy efficiency, innovative technologies and materials need to be introduced in the manufacturing of ventilation fans.

Manufacturing of office machinery equipment offers industrial solutions that are efficient, reliable, and meet modern demands. Applying automation technology to the manufacturing of office machinery equipment can enhance product performance and production efficiency. For example, automated assembly lines and intelligent monitoring systems can achieve faster production speeds and higher production quality. In the future, the manufacturing of office machinery equipment will move towards increased efficiency, sustainability, intelligence, and eco-friendliness.

In conclusion, with the continuous development and innovation in the fields of displacement detection, material testing, automation, manufacturing of office machinery equipment, and manufacturing of ventilation fans, future trends will lean towards increased automation, efficiency, sustainability, and intelligence. These trends will have a significant impact on improving production efficiency, reducing costs, and enhancing product quality, creating more development opportunities for related industries.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)