近年來,工業界對於模具的需求不斷增加,尤其是工業用途的模具,它們在各個行業中扮演著至關重要的角色。而隨著科技不斷進步,模具的製造方式也在不斷改變,加工材料的選擇也越來越多樣化。在這個發展趨勢下,客製化加工已成為未來模具製造的重要方向之一。

模具製造的加工方式已逐漸遷移至數位製造。利用先進的電腦輔助設計(CAD)和電腦輔助製造(CAM)技術,工程師可以輕鬆設計出複雜的模具結構,並且能夠進行快速原型製作,大大節省了製造時間和成本。這種客製化加工的趨勢將為工業模具製造帶來更大的便利性和靈活性。

而在材料方面,工業用模具通常需要具有防撞防震的特性,以保護所加工產品的安全性和品質。近年來,橡膠材料在工業模具製造中的應用越來越廣泛。橡膠材料具有優異的彈性和抗震性能,能夠有效減少意外事故發生的機率,同時還能夠提供良好的密封性和耐磨性。這種特性使得橡膠成為理想的材料選擇,促進了工業用橡膠製品製造的發展。

此外,客製化也成為模具製造風潮中的重要趨勢。不同行業對於模具的需求各異,因此許多廠商開始提供客製化的服務,以滿足不同客戶的需求。這種客製化加工的模具能夠確保產品的精確度和品質,同時還能夠減少材料的浪費,提高生產效率。客製化加工的趨勢將使得工業模具製造更加專業化和差異化。

總而言之,未來工業模具製造將朝著客製化、數位化、材料多樣化的方向發展。隨著科技的不斷進步,工業模具製造將變得更加高效、精確和便捷,並且能夠更好地滿足不同行業的需求。同時,橡膠製品製造在工業模具製造中的應用也將得到進一步推廣和發展。

關鍵字: Mold, Industrial, Processing, Materials, Customization

標題: The Future Trend of Customized Industrial Mold Manufacturing

In recent years, there has been an increasing demand for molds in the industrial sector, especially for industrial purposes. Molds play a crucial role in various industries, and with advancing technology, the manufacturing methods and material choices for molds have become more diverse. In this developing trend, customization has emerged as one of the key directions for future mold manufacturing.

The manufacturing process for molds has gradually shifted towards digital fabrication. Utilizing advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, engineers can easily design complex mold structures and rapidly create prototypes, significantly saving manufacturing time and costs. This trend towards customization will bring greater convenience and flexibility to the field of industrial mold manufacturing.

Regarding materials, industrial molds often need to possess anti-collision and shock-absorbing properties to ensure the safety and quality of the products being processed. In recent years, rubber materials have been increasingly used in the manufacturing of industrial molds. Rubber materials exhibit excellent elasticity and seismic resistance, effectively reducing the probability of accidents. Furthermore, rubber provides good sealing and wear-resistant properties, making it an ideal material choice for industrial mold manufacturing. This has driven the development of industrial rubber product manufacturing.

Moreover, customization has become a significant trend in mold manufacturing. Different industries have unique requirements for molds, leading many manufacturers to offer customized services to meet diverse customer needs. Customized molds ensure the precision and quality of the products while reducing material waste and improving production efficiency. This trend in customization will make industrial mold manufacturing more specialized and differentiated.

In conclusion, the future of industrial mold manufacturing is heading towards customization, digitalization, and material diversification. With advancing technology, mold manufacturing will become more efficient, accurate, and convenient, meeting the varying needs of different industries. Additionally, the application of rubber products in industrial mold manufacturing will continue to expand and develop.

關鍵字: Mold, Industrial, Sports, Impact Resistance, Processing, Materials, Information, Customization, Rubber Product Manufacturing, Industrial Rubber Product Manufacturing

標題: The Future of Industrial Mold Manufacturing and Rubber Product Applications in Sports

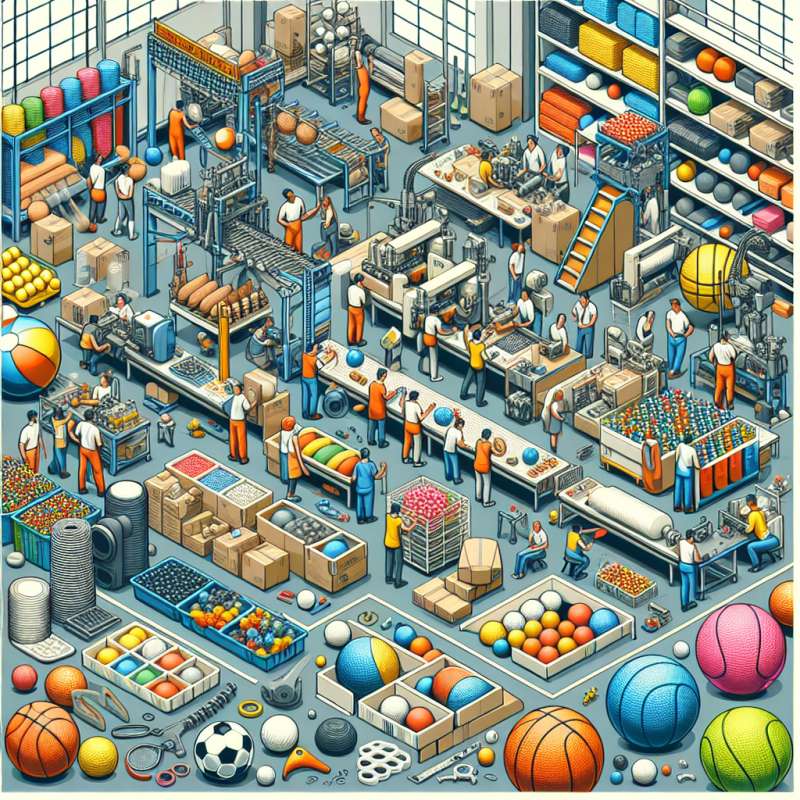

In recent years, the demand for molds in the industrial sector has been continuously increasing, especially for sports-related applications that require impact resistance. Industrial molds play a vital role in various athletic equipment and facilities. With the advancement in technology and material processing, the future of industrial mold manufacturing and its applications in sports is poised for remarkable development.

Industrial mold manufacturing has seen a shift towards digitalization and customization. The use of advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies has enabled engineers to design complex molds with ease and create rapid prototypes. This digitalized approach has not only reduced manufacturing time and costs but has also provided increased flexibility for customization. This trend aligns with the growing demand for tailor-made sports equipment and facilities for athletes of different disciplines.

In terms of materials, impact resistance is a crucial requirement for sports-related molds. Rubber, as a versatile material, has demonstrated excellent shock-absorption and durability properties, making it an ideal choice for molding sports-related components. The application of rubber materials allows for enhanced safety and protection in sports activities, mitigating the risk of injuries. The development of industrial rubber product manufacturing has further expanded the possibilities for the production of sports equipment, such as helmets, padding, and soles.

Additionally, the combination of information technology and industrial mold manufacturing has led to the creation of smart sports equipment. With embedded sensors and data tracking capabilities, these customized molds can produce intelligent sports products that provide real-time feedback on performance and assist in injury prevention. This integration of technology and industrial molds brings about a new era of sports equipment, further enhancing athletes' training and performance.

In conclusion, the future of industrial mold manufacturing in sports lies in the digitalization, customization, and incorporation of advanced materials. Through the utilization of digital technologies and rubber materials, sports-related molds can meet the demand for impact resistance and tailor-made equipment. Furthermore, the integration of information technology opens doors to smart sports equipment that revolutionizes athletes' training and performance monitoring capabilities. The synergy between industrial mold manufacturing and sports applications bears promising prospects for innovation and advancement in the athletic world.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)