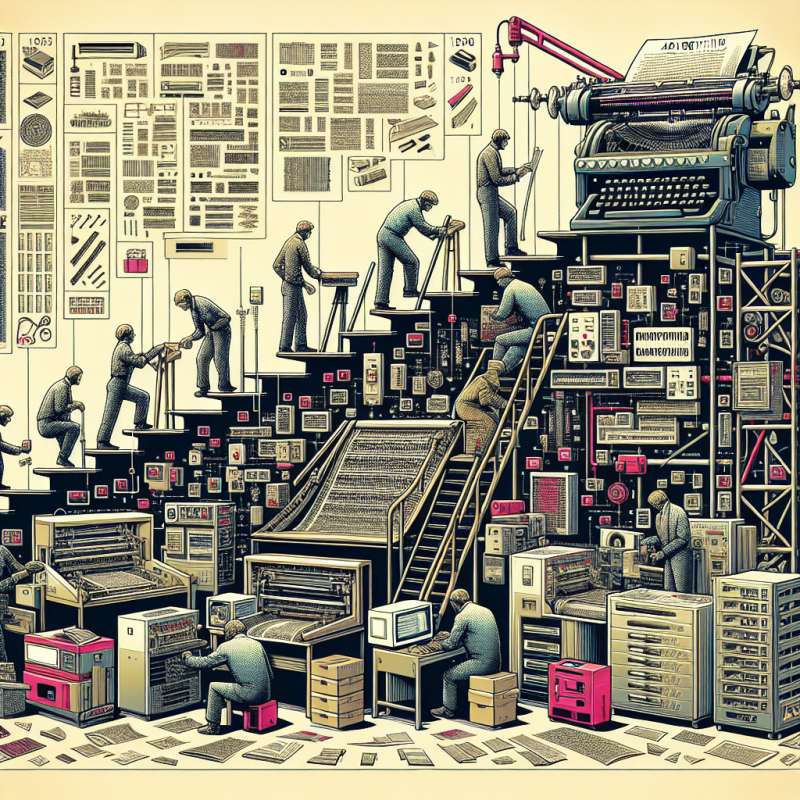

在印刷業的發展中,印刷品質一直是個不可忽視的重要因素。印刷品質的提升不僅關乎印刷品的美觀度,更與行業的競爭力和顧客滿意度息息相關。如何提高印刷品質,一直是印刷業界關注的焦點。近年來,隨著科技的進步,數碼印刷和裝幀印刷作為新興的印刷技術,開始在印刷品質的提升上發揮著重要的作用。

數碼印刷是利用電腦技術和數位設備將數據直接轉化為印刷品的印刷技術。相比傳統印刷,數碼印刷具有快速、靈活、可定制性高等優勢。它不需要製版,印刷過程簡單方便,並且可以根據客戶需求進行快速變更。數碼印刷的出現和發展,讓印刷品質提高到了一個新的水平。

然而,單純依靠數碼印刷無法滿足所有的印刷需求。這時候裝幀印刷作為一種傳統的印刷工藝技術,扮演了重要的角色。裝幀印刷是指將裝訂和裝幀製作相結合的印刷方式。它包括書籍裝訂、平版印刷、裝幀設計等多個環節。裝幀印刷的特點是精緻、持久、具有藝術性和觀賞性。它可以使印刷品更具價值感和觸感,進一步提升印刷品質。

因此,結合數碼印刷和裝幀印刷的優點,將是提升印刷品質的有力方式。這種結合能夠同時擁有數碼印刷的靈活性和快速性,以及裝幀印刷的藝術性和觀賞性。例如,在數碼印刷的基礎上,通過裝幀印刷可以為印刷品增加紙張的厚度和質地,使得印刷品更具質感。同時,裝幀印刷也可以為數碼印刷提供更加完美的書脊和封面設計,使得印刷品更具觀賞性。

隨著市場對印刷品質要求的不斷提高,數碼印刷和裝幀印刷的結合在印刷市場中已經得到廣泛應用。這種結合不僅滿足了客戶對印刷品質的追求,同時也帶來了新的商機和發展機遇。然而,在實際應用中,印刷廠商需要仔細考慮印刷工藝流程、印刷設備和印刷材料等多個因素,確保產品能夠達到預期的印刷效果。

綜上所述,數碼印刷和裝幀印刷的結合為印刷品質的提升開闢了新的道路。這種結合不僅具有較高的靈活性和定制性,同時也能為印刷品增加藝術性和觀賞性。在具體應用時,印刷廠商需要綜合考慮印刷工藝流程、印刷設備和印刷材料等因素,確保產品能夠達到預期的印刷效果。隨著印刷市場的不斷發展,印刷品質的提升將成為印刷業界的持續追求。

關鍵字: Print quality, Digital printing, Binding printing

標題: Improving Print Quality: Exploring the Combination of Digital and Binding Printing

Print quality has always been an important factor in the development of the printing industry. Improving print quality is not only about the aesthetics of printed materials, but also closely related to competition and customer satisfaction. How to improve print quality has been a focus of the printing industry. In recent years, with the advancement of technology, digital printing and binding printing have emerged as new printing technologies that play a crucial role in enhancing print quality.

Digital printing is a printing technology that uses computer technology and digital devices to directly convert data into printed materials. Compared to traditional printing, digital printing offers advantages such as speed, flexibility, and high customization. It eliminates the need for plate making and simplifies the printing process, allowing for quick changes based on customer requirements. The emergence and development of digital printing have taken print quality to a new level.

However, relying solely on digital printing cannot meet all printing needs. This is where binding printing, a traditional printing process, plays an important role. Binding printing combines binding and packaging production, encompassing book binding, offset printing, and packaging design. Binding printing is known for its precision, durability, artistic value, and visual appeal. It enhances the value and tactile experience of printed materials, further improving print quality.

Therefore, the combination of digital printing and binding printing is a powerful way to enhance print quality. This combination leverages the flexibility and speed of digital printing, as well as the artistic value and visual appeal of binding printing. For example, by combining digital printing with binding printing, the thickness and texture of paper can be increased to add a tactile feel to printed materials. Additionally, binding printing can provide perfect spine and cover designs for digital printing, increasing the visual appeal of printed materials.

With the increasing demand for print quality in the market, the combination of digital printing and binding printing is widely applied in the printing industry. This combination not only meets customers' pursuit of print quality but also brings new business opportunities and development prospects. However, in practical applications, print manufacturers need to carefully consider factors such as printing processes, equipment, and materials to ensure that the products achieve the desired print effects.

In conclusion, the combination of digital printing and binding printing opens up new possibilities for improving print quality. It offers high flexibility and customization, as well as artistic value and visual appeal. In specific applications, print manufacturers need to consider various factors, including printing processes, equipment, and materials, to ensure that products achieve the desired print effects. With the continuous development of the printing market, the pursuit of print quality will remain a constant endeavor for the printing industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)