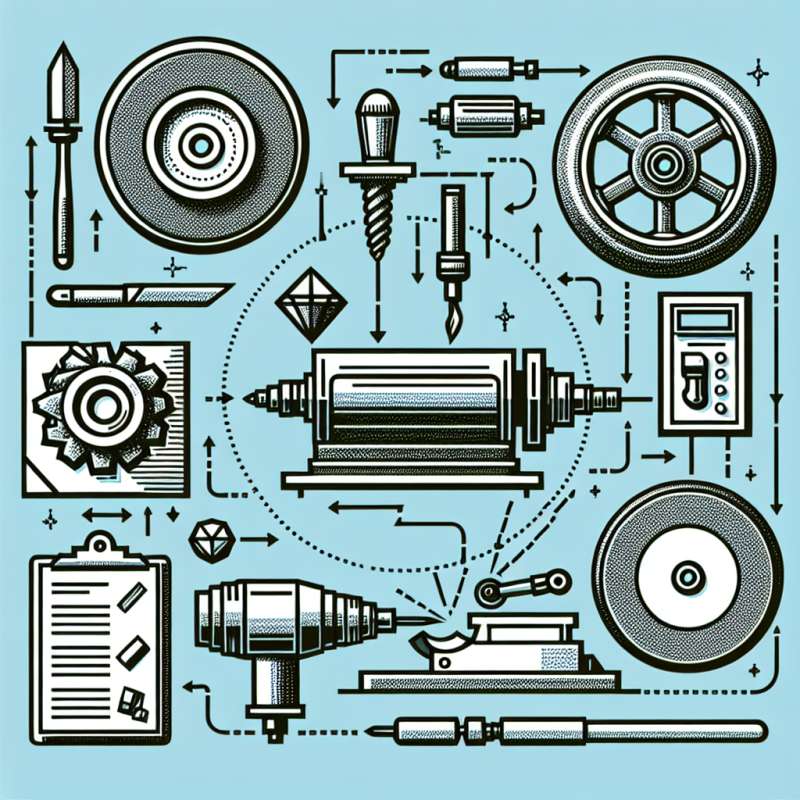

金剛石是一種非常堅硬且耐磨的材質,因此被廣泛應用於切削工具的製造中。金剛石切削工具的製造過程需要遵循特定的步驟和使用特殊的材料。本文將介紹金剛石切削工具的製造過程以及其在各個領域的應用。

金剛石切削工具的製造始於選擇適當的基材。常見的基材包括碳化鈷、硬質合金和超硬材料等。基材的選擇要考慮到金剛石的附著性和撞擊抗力等因素。一旦選擇好基材,就需要將金剛石磨成合適的形狀和尺寸。砂輪磨削是最常見的方式之一,它可以將金剛石塊磨成所需的形狀。在砂輪磨削過程中,要控制砂輪尺寸和顆粒磨輪的選擇,以確保金剛石切削工具的最終形狀和品質。

金剛石切削工具的製造過程不僅僅是將金剛石加工成所需形狀的過程,還需要進行一系列的加工步驟。例如,使用特殊的熱處理技術可以提高金剛石的硬度和耐磨性。此外,還可以通過鍍膜和鍍金剛石等方法來改善金剛石切削工具的性能。

金剛石切削工具由於其硬度高、耐磨性好和熱穩定性高等優點,被廣泛應用於鋼鐵加工、汽車製造、航空航太等領域。在鋼鐵加工中,金剛石切削工具能夠快速而精確地切削各種硬度的金屬材料。在汽車製造行業中,金剛石切削工具能夠提高加工效率並提供更高的加工質量。在航空航太領域中,金剛石切削工具的優異性能使其成為製造難加工材料的首選。

總結起來,金剛石切削工具的製造過程需要考慮材質選擇、砂輪磨削、尺寸控制和顆粒磨輪的選擇等因素。金剛石切削工具以其優異的硬度和耐磨性被廣泛應用於各個行業,提高了切削效率和加工質量。

關鍵字: Manufacturing, Material, Cutting Tools, Diamond

Title: Manufacturing and Applications of Diamond Cutting Tools

Article:

Diamond, known for its exceptional hardness and wear resistance, is widely used in the manufacturing of cutting tools. The process of manufacturing diamond cutting tools involves specific steps and the use of special materials. This article will introduce the manufacturing process of diamond cutting tools and their applications in various industries.

The manufacturing of diamond cutting tools starts with the selection of an appropriate base material. Common base materials include cobalt carbide, hard alloy, and super-hard materials. The choice of base material depends on factors such as the adhesion of diamond and impact resistance. Once the base material is chosen, the diamond needs to be shaped and sized accordingly. Grinding with a grinding wheel is one of the most common methods used to shape diamond into the desired form. During the grinding process, it is crucial to control the size of the grinding wheel and the selection of grit size to ensure the final shape and quality of the diamond cutting tool.

The manufacturing process of diamond cutting tools goes beyond reshaping the diamond into the desired form; it also involves a series of processing steps. For example, special heat treatment techniques can enhance the hardness and wear resistance of diamond. Additionally, coating and diamond plating methods can be employed to improve the performance of diamond cutting tools.

Diamond cutting tools are widely applied in industries such as steel processing, automotive manufacturing, and aerospace due to their high hardness, excellent wear resistance, and thermal stability. In steel processing, diamond cutting tools can cut various metal materials of different hardness quickly and accurately. In the automotive industry, diamond cutting tools can improve processing efficiency and provide higher quality results. In the aerospace field, the superior performance of diamond cutting tools makes them the preferred choice for machining difficult-to-process materials.

In conclusion, the manufacturing process of diamond cutting tools involves considerations such as material selection, grinding, size control, and grit selection. Diamond cutting tools are extensively used in various industries, enhancing cutting efficiency and processing quality, thanks to their exceptional hardness and wear resistance.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)